Construction site control cabinet

A technology for control cabinets and construction sites, which is applied in the direction of electrical components, substation/power distribution device shells, substation/switchgear cooling/ventilation, etc. It can solve problems such as confusing switches and wiring arrangements, accidents, etc., and achieve stable control cabinets. The effect of not being easily blown down by the wind

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

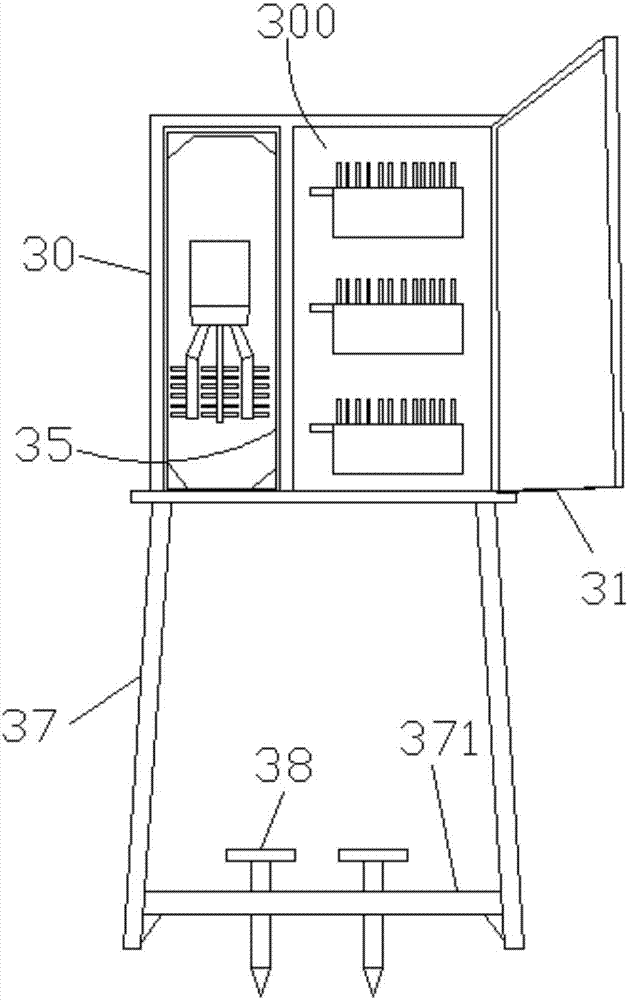

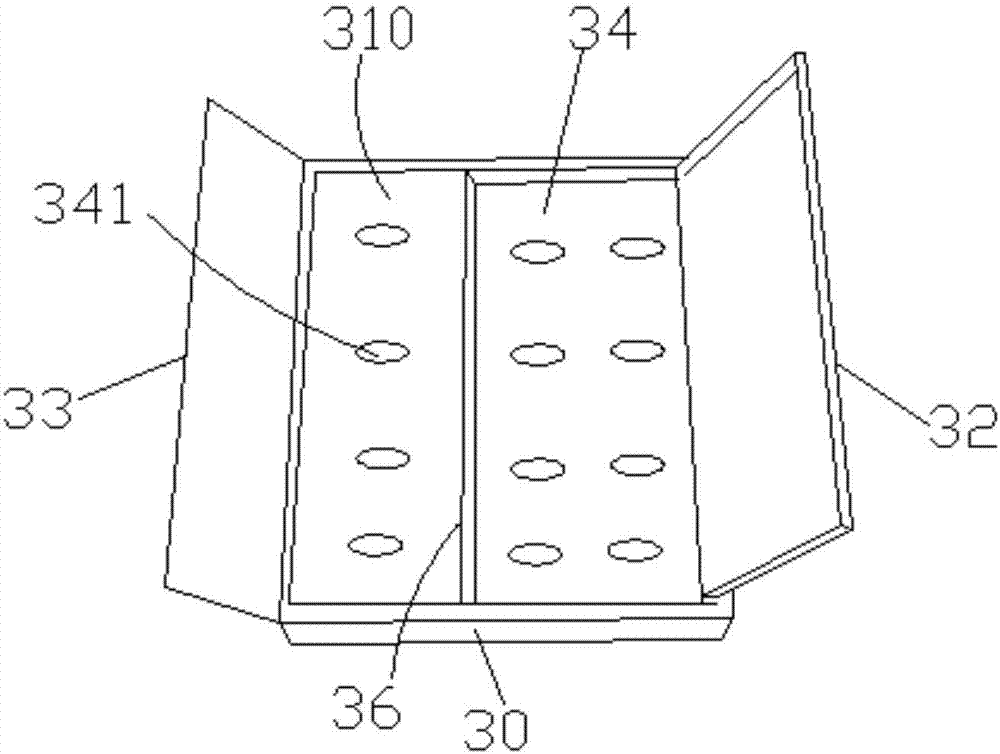

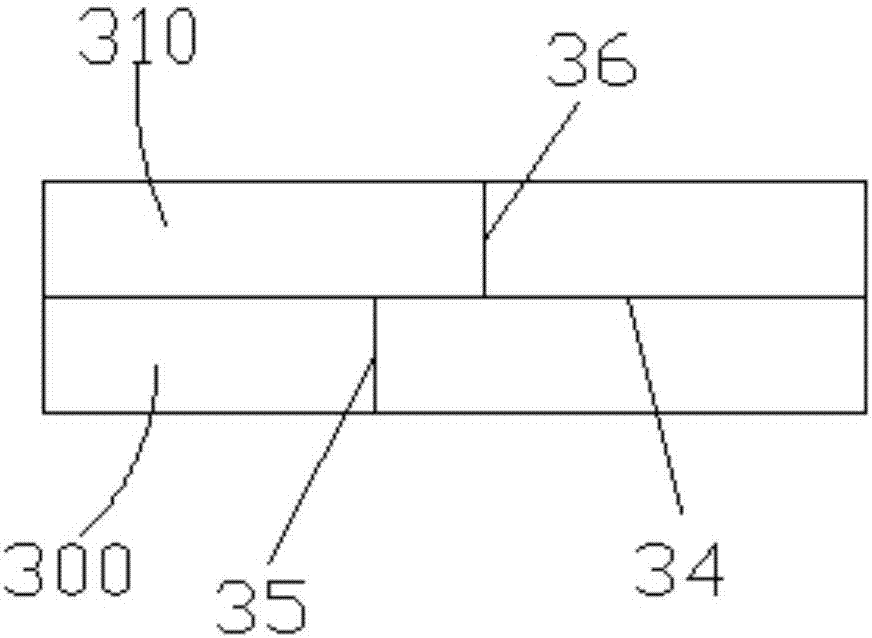

[0013] Such as Figure 1 to Figure 3 As shown, the present invention discloses a construction site control cabinet, comprising a cabinet body 30, a first cabinet door 31, a second cabinet door 32, a third cabinet door 33, a first partition 34, a second partition 35, a third partition Plate 36, mounting frame 37 and fixing screw 38, cabinet body 30 is fixed on the mounting frame 37, and fixing screw 38 is threadedly connected on the cabinet body 30, and the first dividing plate 34 is located in the inner chamber of cabinet body 30, and the cabinet body The inner cavity of the body 30 is divided into a front cavity 300 and a rear cavity 310 , the second partition 35 is arranged in the front cavity 300 , and the second partition 35 divides the front cavity 300 into two small cavities. The third partition 36 is disposed in the rear cavity 310 , and the third partition 36 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com