Blade adjusting mechanism of tea picking machine

An adjustment mechanism and tea picking machine technology, which is applied to picking machines, agricultural machinery and implements, harvesters, etc., can solve problems that affect work efficiency, cannot change the arbitrary height of the blade, troublesome positioning screws, etc., and achieve the effect of improving the picking speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

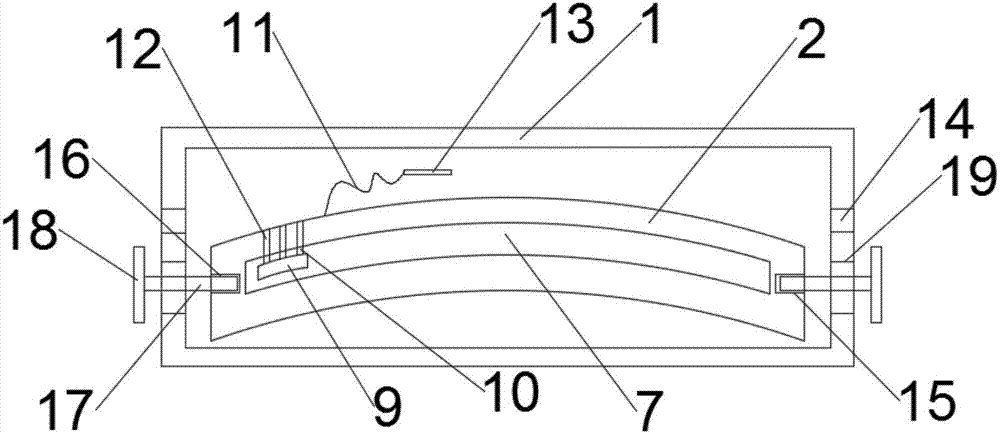

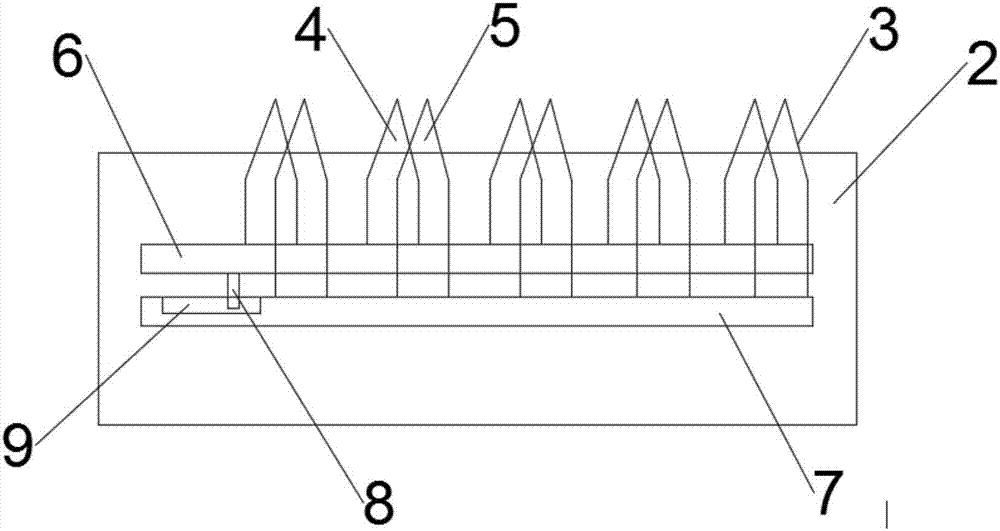

[0022] like figure 1 and figure 2 As shown, the present invention provides a blade adjustment mechanism of a tea picking machine, including a housing 1, the housing 1 includes a bottom plate 2, and several sets of cutting blades 3 are arranged on the front side of the bottom plate 2, and the cutting blades 3 each includes a left blade 4 and a right blade 5, and the inside of the bottom plate 2 is provided with a first drive shaft 6 and a second fixed shaft 7, and the left blade 4 and the right blade 5 are respectively fixed on the first drive shaft 6 and the second fixed shaft 7. On the second fixed shaft 7, a limit plate 8 is provided on the side of the first drive shaft 6, a groove 9 is provided on the side of the second fixed shaft 7, and the limit plate 8 is inserted in the groove 9, The top surface of the second fixed shaft 7 is provided with a number of through holes 10, the through holes 10 are located directly above the groove 9, the upper surface of the bottom plate...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap