A method of improving the storage period of fried fishbone food

A technology for frying fish bones and food storage, which is applied in the storage field of fish food products, can solve the problems affecting the taste and quality of food, and achieve the effect of increasing the storage period and improving the crispy taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

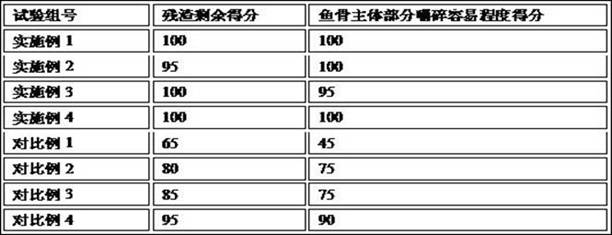

Examples

Embodiment 1

[0020] A method for improving the storage life of fried fishbone food, it goes through the following steps:

[0021] (1) Spray 14 parts by weight of treatment liquid on the surface of 1000 parts by weight of fried fishbone food and mix uniformly, said treatment solution comprises 0.72% butyl hydroxyanisole and 18% corn syrup by weight percentage, 3.5% citric acid, the rest is ethanol;

[0022] (II) Add 17 parts by weight of cornstarch to the fried fishbone food obtained in step I, and mix well;

[0023] (III) Bake the fried fishbone food obtained in step II in an oven at 175 degrees Celsius for 9 minutes;

[0024] (IV) Place the fried fishbone food obtained in step III in a closed reaction kettle, vacuumize to 0.12 atmospheric pressure, and keep for 48 minutes;

[0025] (V) Packing the fried fishbone food obtained in step IV, and storing at a temperature below room temperature.

Embodiment 2

[0027] A method for improving the storage life of fried fishbone food, it goes through the following steps:

[0028] (1) Spray 10 parts by weight of treatment liquid on the surface of 1000 parts by weight of fried fishbone food and mix uniformly, said treatment solution comprises 1% butyl hydroxyanisole and 20% corn syrup by weight percentage, 5% citric acid, the rest is ethanol;

[0029] (II) Add 20 parts by weight of cornstarch to the fried fishbone food obtained in step I, and mix well;

[0030] (III) Bake the fried fishbone food obtained in step II in an oven at 160 degrees Celsius for 12 minutes;

[0031] (IV) Place the fried fishbone food obtained in step III in a closed reaction kettle, vacuumize to 0.3 atmospheric pressure, and keep for 60 minutes;

[0032] (V) Packing the fried fishbone food obtained in step IV, and storing at a temperature below room temperature.

Embodiment 3

[0034] A method for improving the storage life of fried fishbone food, it goes through the following steps:

[0035] (1) Spray 20 parts by weight of treatment liquid on the surface of 1000 parts by weight of fried fishbone food and mix uniformly, said treatment solution comprises 0.5% butyl hydroxyanisole and 10% corn syrup by weight percentage, 2% citric acid, the rest is ethanol;

[0036] (II) Add 10 parts by weight of cornstarch to the fried fishbone food obtained in step I, and mix well;

[0037] (III) Bake the fried fishbone food obtained in step II in an oven at 180 degrees Celsius for 6 minutes;

[0038] (IV) Place the fried fishbone food obtained in step III in a closed reaction kettle, vacuumize to 0.1 atmospheric pressure, and keep for 30 minutes;

[0039] (V) Packing the fried fishbone food obtained in step IV, and storing at a temperature below room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com