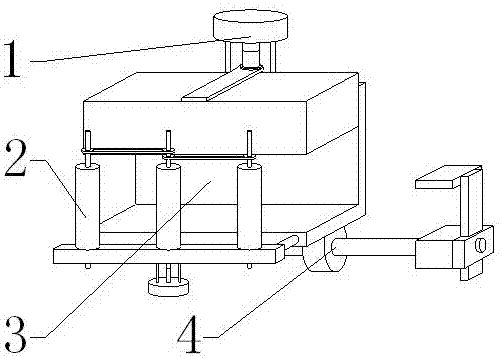

Plane correcting device for silicon steel column

A technology of plane correction and silicon steel, which is applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of increasing non-renewable energy consumption, increasing the workload of users, and long working hours, so as to increase the non-renewable energy consumption. Energy consumption, high correction effect, short working time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

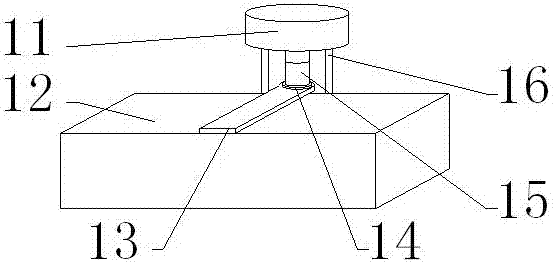

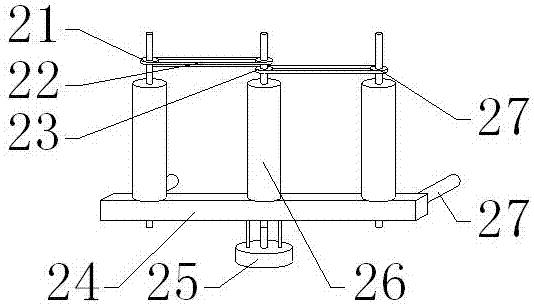

[0029]Specific embodiments: before the user uses the present invention, the user first checks the present invention, checks whether the present invention is intact, replaces it if it is damaged, and uses it if it is intact. During use, the user checks the volume size of the silicon steel column Observe, then the user moves the solid bar 24 back and forth, and the fixed bar 24 moves back and forth to drive the slide bar 27 to move back and forth. When the fixed bar 24 moves to a suitable position, the user moves the limit block on the slide bar 27 to The sliding rod 27 is fixed at the limit, and then the user starts the rotating motor 25, the rotating motor 25 works to drive the roller shaft 26 to rotate, and the roller shaft 26 rotates to drive the second runner 23 to rotate, because the first runner 21 and the second runner 23 pass through the belt 22 Connected, so runner two 23 rotates and drives runner one 21 to rotate, and because runner two 23 is connected with runner thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com