Three-point self-centering device

A self-centering and fixed disk technology, applied in the field of mechanical parts processing, can solve the problems of high synchronization and high concentricity, and can not fully guarantee the complete synchronization of the three-jaw clamping progress, and achieve the effect of good concentricity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

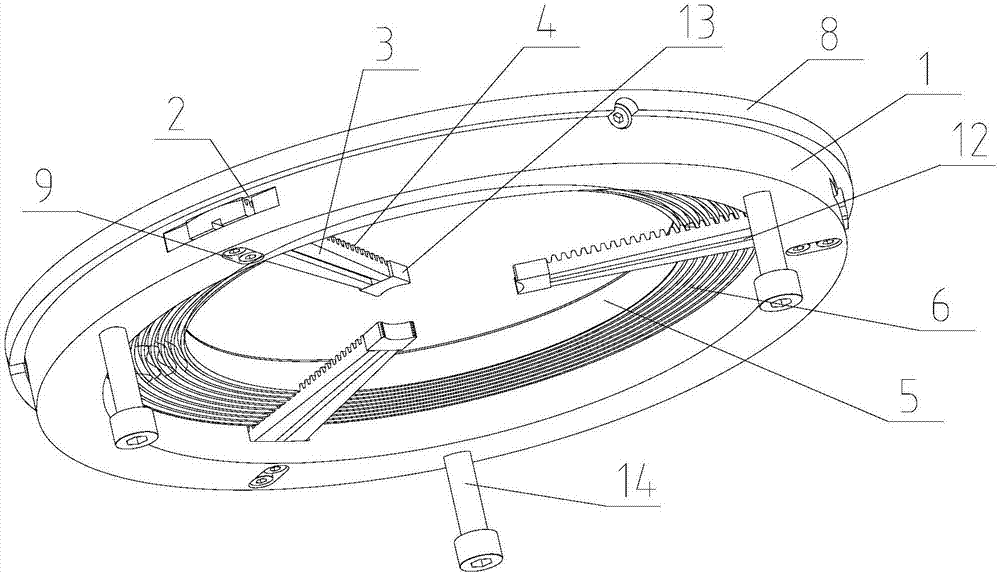

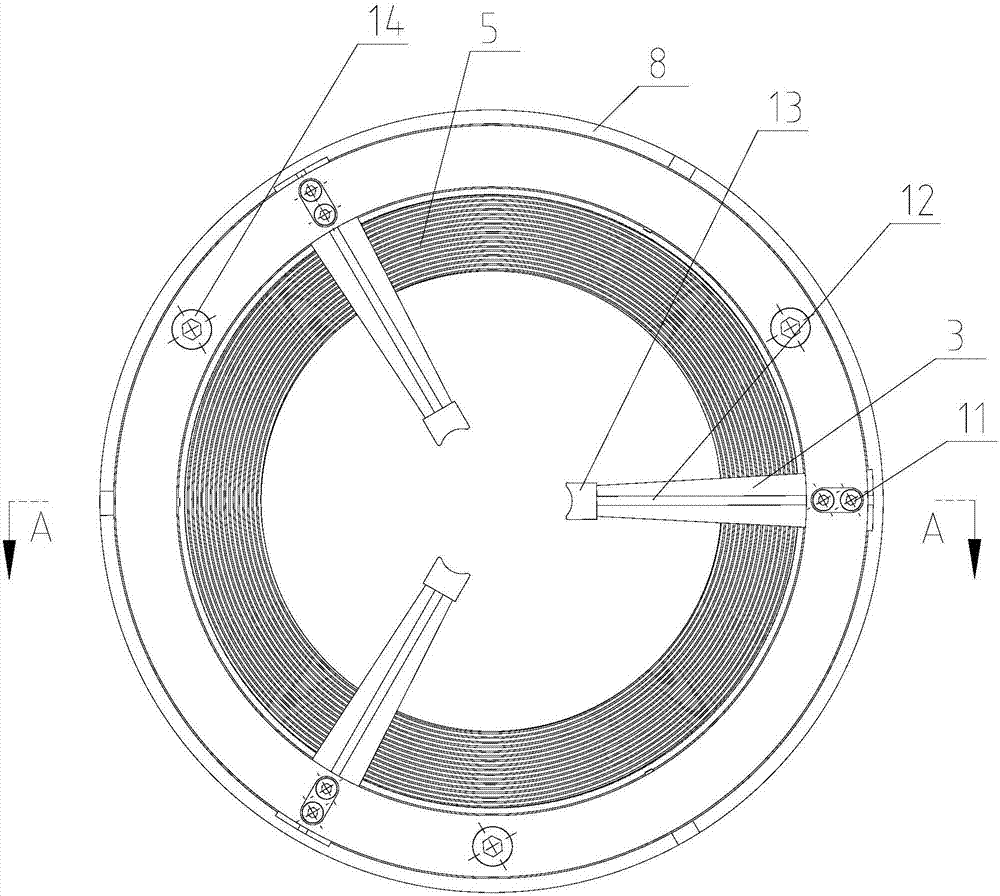

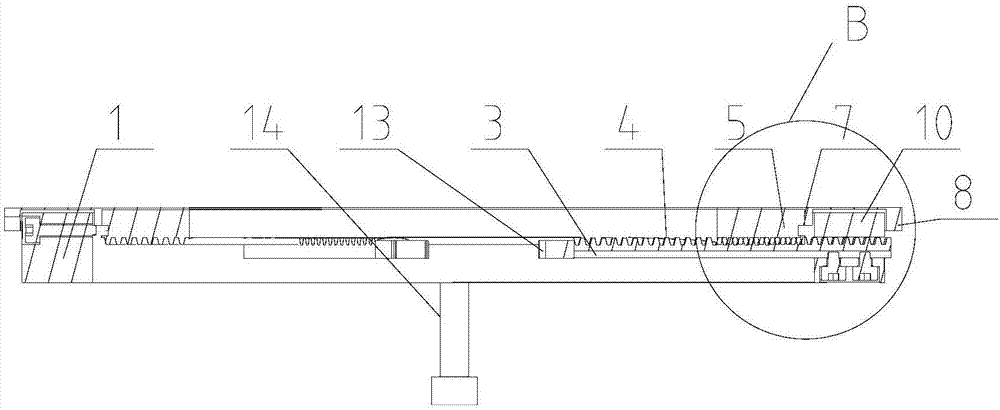

[0016] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, and only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0017] Such as Figure 1 to Figure 4 A three-finger self-centering device shown is the most preferred embodiment of the present invention, including an annular fixed disk 1. The upper surface of the fixed disk 1 is evenly spaced with three draw-in grooves 2, and the adjustment blocks 3 are clamped in the draw-in grooves 2 respectively. Adjusting block 3 ends are fixed with support block 13, and the inner surface of described support block 13 is arc surface, can adapt to workpiece surface radian conveniently.

[0018] In order to facilitate support, three uniform support columns 14 are screw-fastened under the fixed plate 1 . The position of support column 14 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com