Installation equipment for large diameter pipes in tube wells

A pipeline installation, large-diameter technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of pipeline interface welding dead angle, large number of pipeline cutting sections, etc., achieve low operating consumption, reduce pipeline cutting sections, structure and other problems. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

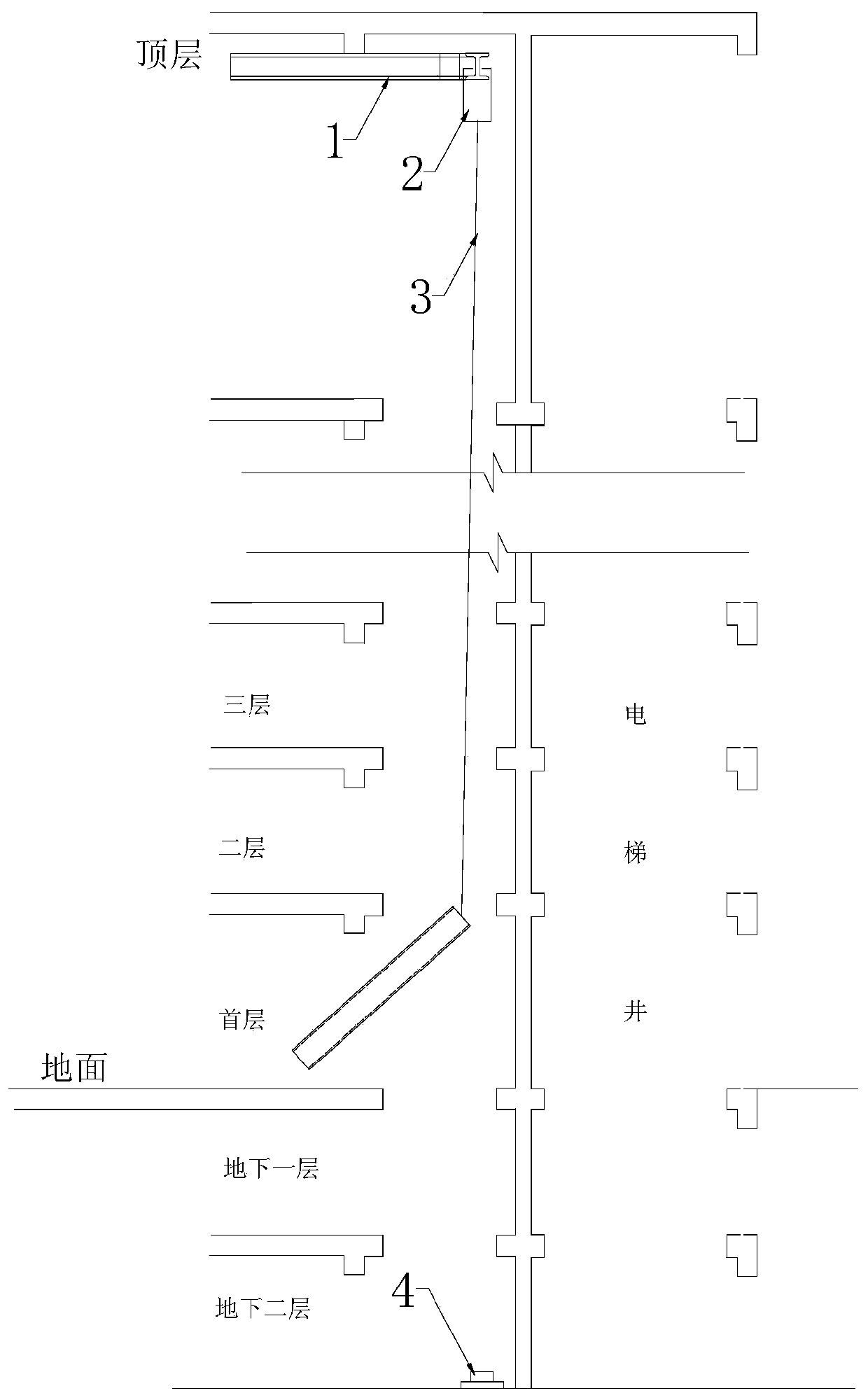

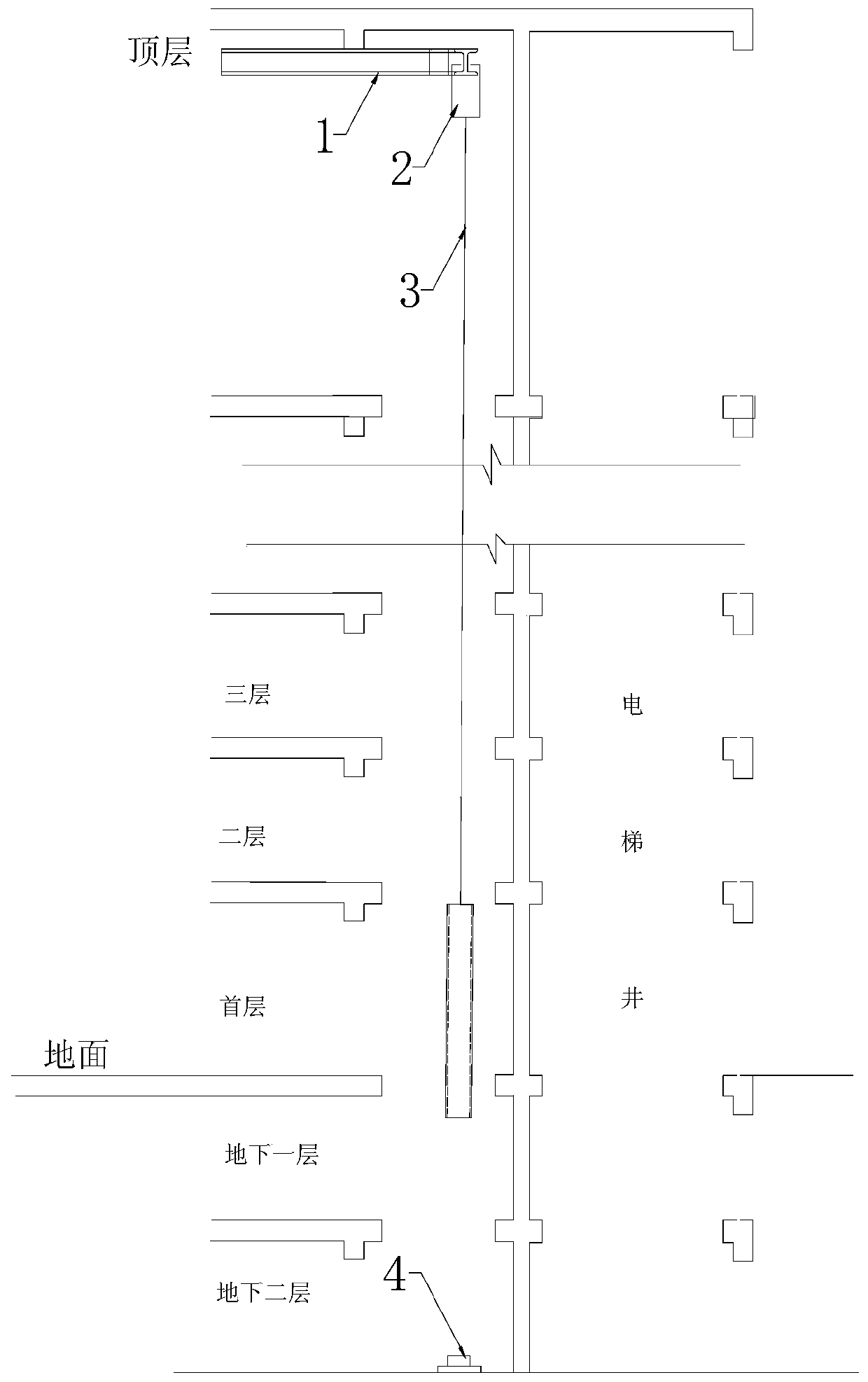

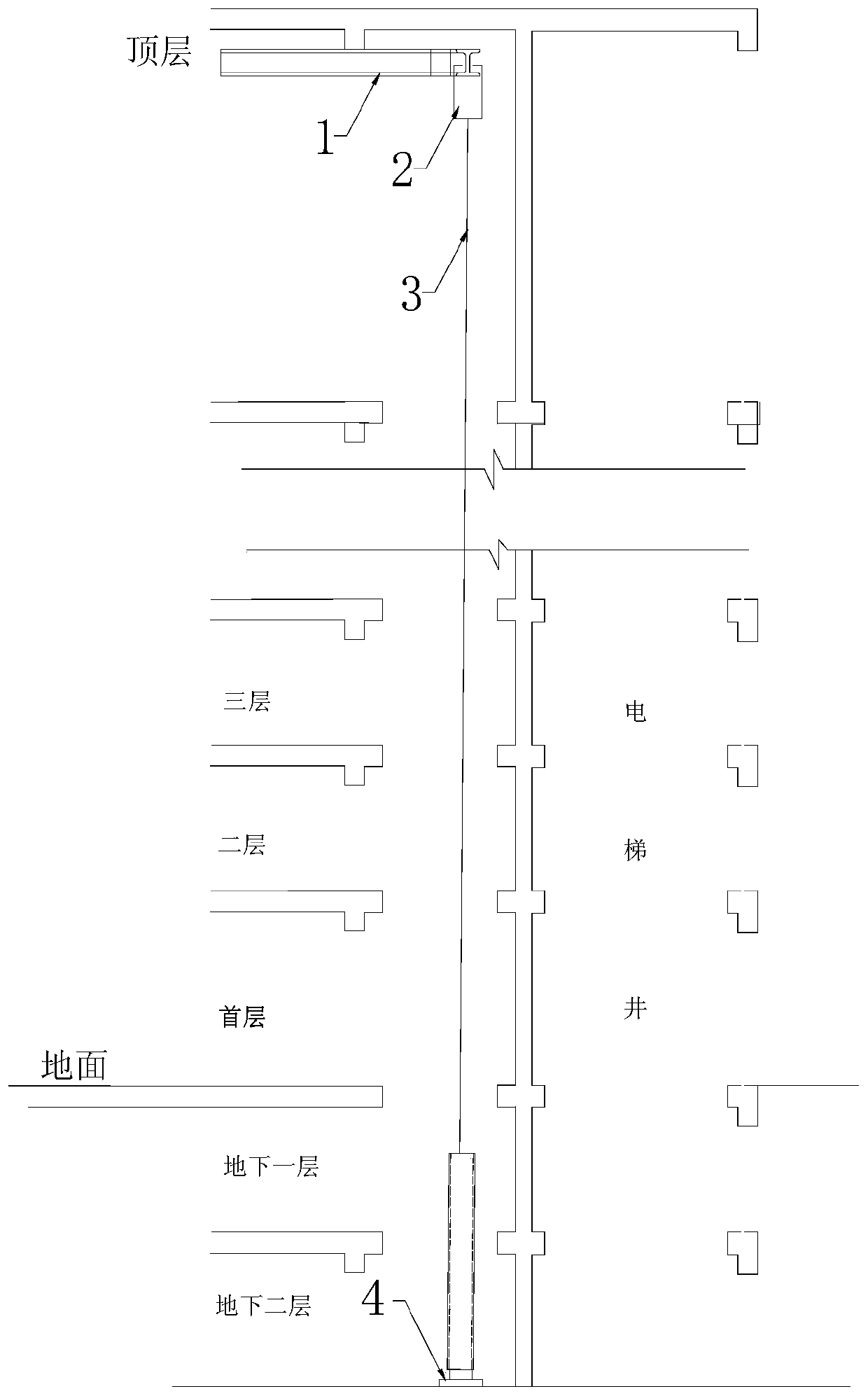

[0019] In the pipeline construction in the prior art, the long pipe is directly hoisted from the top of the pipeline well and sent into the well, but the required hoisting equipment is large, and the implementation cost is very high. When installing the riser in the tube well, if the tower crane has been removed, the external elevator can be used to transport the tube. In high-rise construction, the floor height of each floor is generally between 3-4.5 meters, including the basement. The size of the elevator corresponds to the height of each floor. Due to the size of the elevator Restrictions require the entire tube to be cut off. Existing pipelines are generally six meters long, and each section of the pipeline is cut to a length of 3 meters. These pipelines need to be sent to each floor to prepare for welding, and the transportation workload is heavy. Due to the large number of pipe sections after cutting, the welding work in the well is quite heavy, and the space in the pip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com