Advanced type polisher

A polishing machine and an improved technology, applied in the field of polishing machines, can solve the problems of poor grinding effect and low efficiency, and achieve the effect of good grinding effect and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

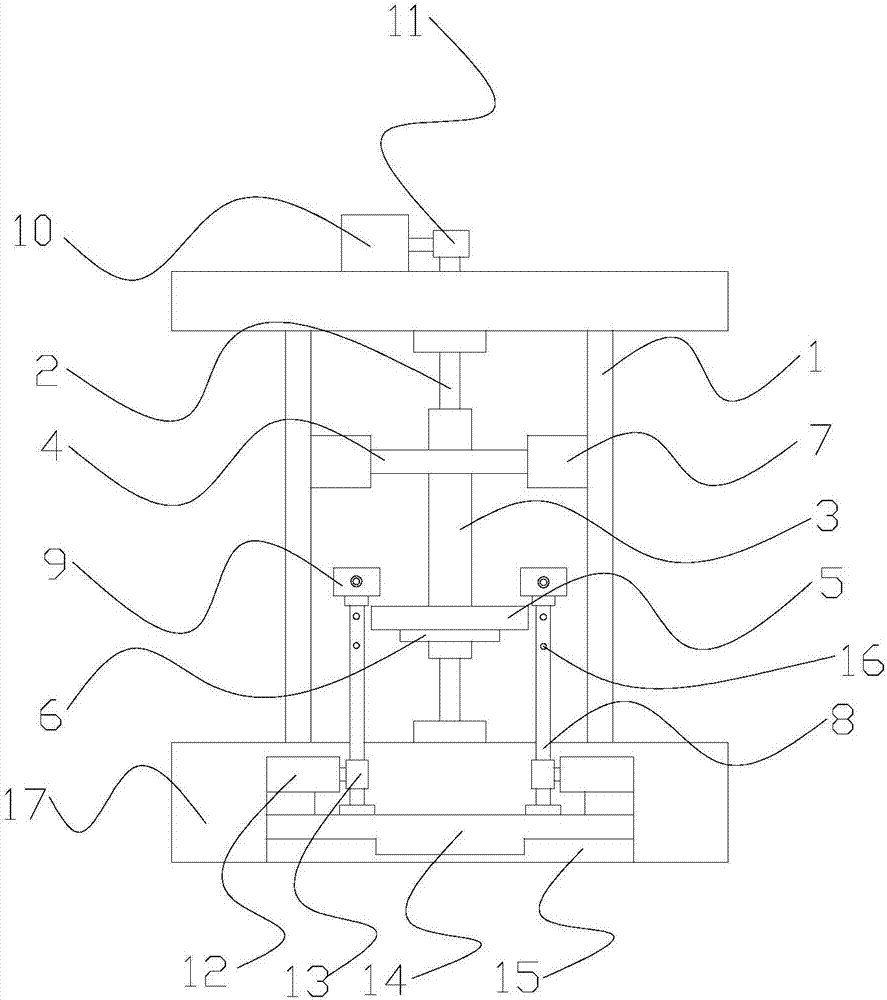

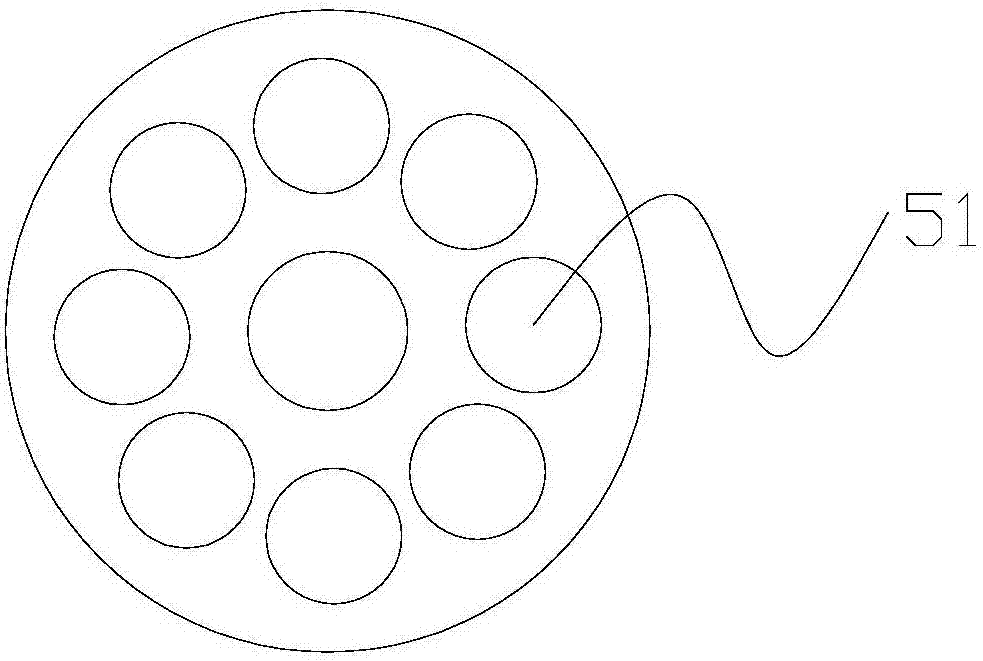

[0018] Such as figure 1 with 2 As shown, the present invention provides an improved polishing machine, comprising: a bin body 1; a lifting assembly, which includes a rotating shaft 2, a sleeve rod 3, an upper fixing ring 4, a lower fixing ring 5, a screw sleeve 6 and two The limit slider 7, the rotating shaft 2 are rotatably arranged in the bin body 1, the side wall of the rotating shaft 2 has an external thread, the sleeve rod 3 is threaded on the rotating shaft 2, and the upper fixing ring 4 sets are fixed on the sleeve On the rod 3, two limit sliders 7 are symmetrically fixed on both sides of the upper fixing ring 4, and a slide rail is symmetrically provided on the inner wall of the warehouse body 1, and a limit slider 7 can be slid up and down. In the slide rail, the lower fixing ring 5 is set on the sleeve rod 3 at the bottom of the upper fixing ring 4, the lower fixing ring 5 and the sleeve rod 3 are in clearance fit, and the screw sleeve 6 is threaded on the lower sle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com