Composite equipment for voltage-sharing membrane electrode assembly

An electrode assembly and composite equipment technology, applied in electrical components, circuits, fuel cells, etc., can solve the problems of unqualified product quality, difficulty in uniform stress on molding, uneven stress on products, etc., to prevent movement and ingenious design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

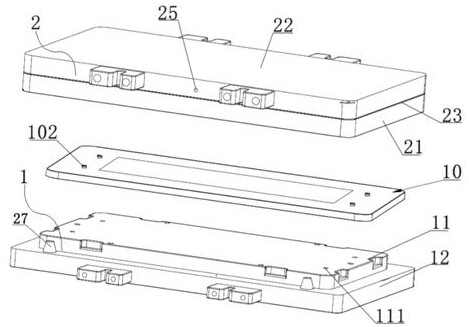

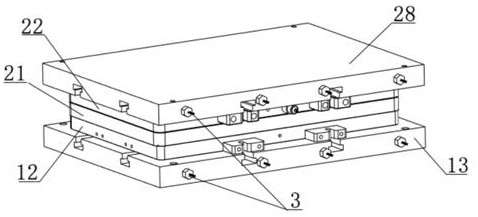

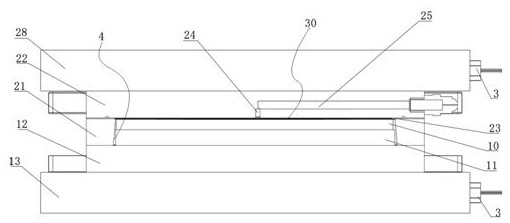

[0031] Refer to the attached Figure 1-10 , a pressure-equalizing membrane electrode assembly compound equipment, which includes a base plate assembly 1, an upper pressure assembly 2, and an upper pressure assembly 2 is designed above the base plate assembly 1, and the upper pressure assembly 2 includes an upper pressure plate 21, an air chamber plate 22, a gas Warehouse pad 23, a rectangular through hole 4 is opened in the middle of the upper pressure plate 21, the upper pressure plate 21 is installed under the gas warehouse plate 22, and a gas warehouse pad 23 is installed between the upper pressure plate 21 and the gas warehouse plate 22, and the gas warehouse pad 23 is covered in a rectangular shape. Above the through hole 4, the upper pressure plate 21 and the air silo pad 23 form an air silo chamber; a circular groove 24 is designed at the lower end of the middle of the air silo plate 22, and a hole 25 is designed on one side of the bottom of the circular groove 24. The h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com