Concrete preparation machinery for water conservancy construction

A concrete and mechanical technology, applied in the field of concrete preparation machinery, can solve the problems of different impact force of materials, large manpower consumption, interference in weighing process, etc., and achieve the effect of uniform impact force and accurate weighing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

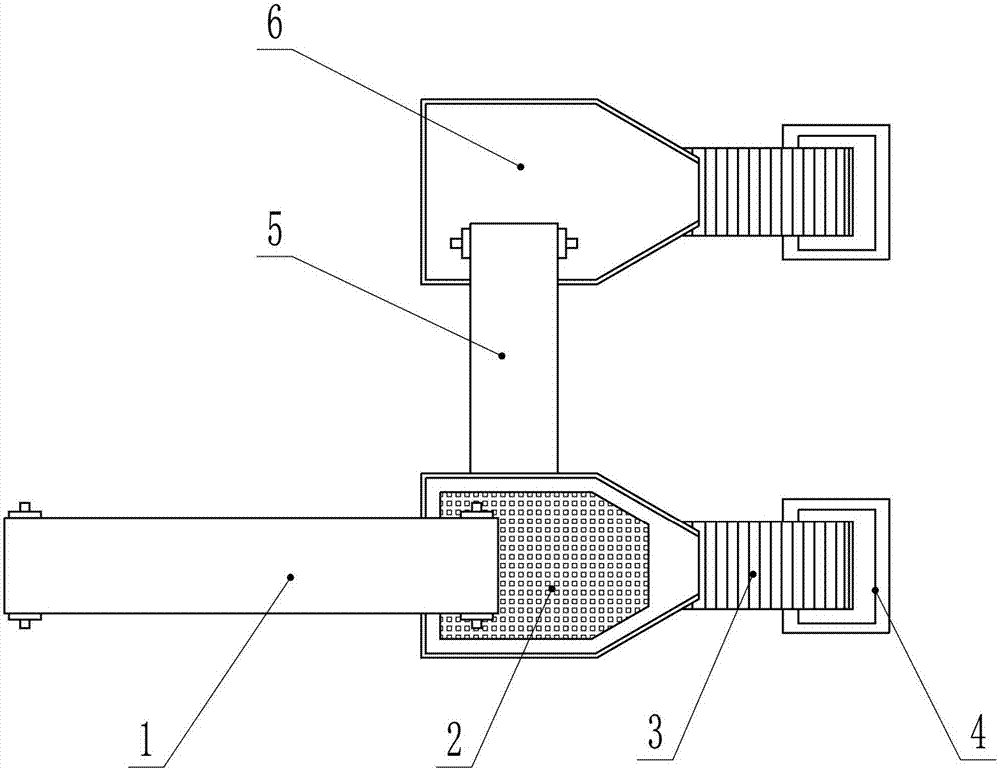

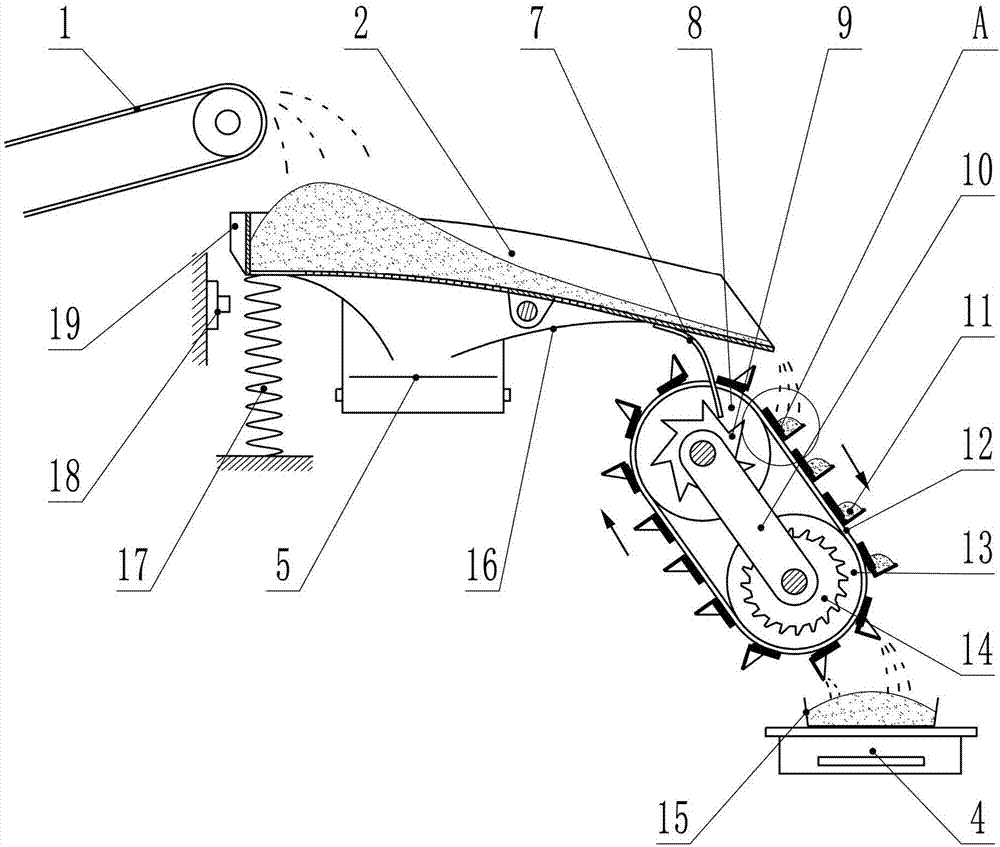

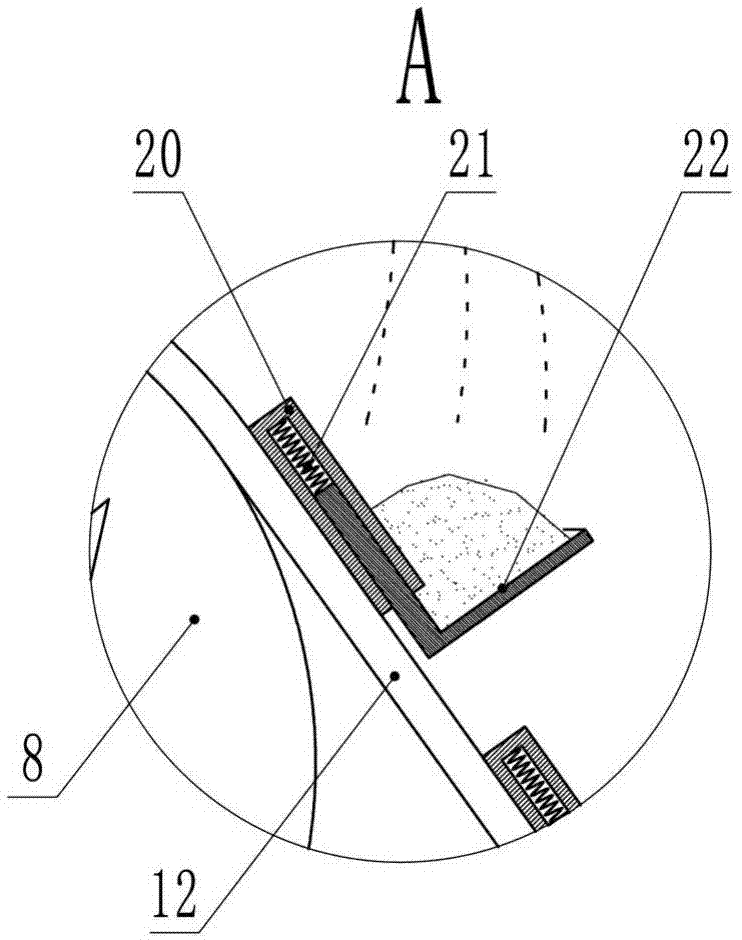

[0023] In embodiment 1 such as figure 1 , 2 , 3, the present embodiment includes a conveyor belt, a frame body, a vibrating screen 2, a lower hopper 6, a bucket conveyor 3 and a weighing assembly 4. In order to facilitate the display of the internal structure, the frame structure has been partially omitted in the figure, and only the part connected to other structures is drawn, that is, the straight line with hatching in the figure (except for the section line). The frame structure is used to support, connect and fix other structures. Since the specific structure of the frame is determined by the position and size of other structures and has no impact on the working principle of the present invention, its specific structure will not be repeated.

[0024] The conveyor belts include a No. 1 conveyor belt 1 and a No. 2 conveyor belt 5. The end of the No. 1 conveyor belt 1 is located above the vibrating screen 2, and is fed into the vibrating screen 2 through the No. 1 conveyor b...

Embodiment 2

[0035] In embodiment 2, such as Figure 4 , 5 As shown, the present embodiment includes a conveyor belt, a frame body, a vibrating screen 2, a lower hopper 6, a bucket conveyor 3 and a weighing assembly 4. Wherein the conveyor belt, the vibrating screen 2, the lower hopper 6, and the bucket conveyor 3 are the same in structure and connection relationship as in Embodiment 1, and will not be repeated in this embodiment. The frame structure is adaptively changed according to the change of the structure of the weighing assembly 4 . The difference between this embodiment and Embodiment 1 mainly lies in the change of the weighing assembly 4 .

[0036] Described installation assembly 4 comprises No. 1 set pan frame 38, No. 1 crossbeam 28, No. 2 crossbeam 24 and dolly 27, and described No. 1 set pan frame 38 is fixed on the frame body (or it can be said that frame body a part of it), placed obliquely, the front is high and the back is low, the No. 1 tray rack 38 is used to place th...

Embodiment 3

[0042] In Embodiment 3, this embodiment is an ore feeding device. Such as Figure 6 , 7 As shown, the present embodiment includes a conveyor belt, a crusher 61 , a frame body, a vibrating screen 2 , a bucket conveyor 3 and a weighing assembly 4 . For ease of description, the outlet direction of the vibrating screen 2 is set as the front, and the opposite direction is the back.

[0043] The conveyor belts include a feed conveyor belt 60 and a return conveyor belt 62 . The head end of the feeding conveyor belt 60 is located at the stockyard, and its feeding method can be manual feeding or mechanical feeding. The end of the feeding conveyor belt 60 is located above the rear end of the vibrating screen 2 . The head end of the return conveyor belt 62 is located below the outlet of the vibrating screen 2, the end of the return conveyor belt 62 is located at the feed inlet of the crusher 61, and the discharge port of the crusher 61 is located at the feeding conveyor belt 60. In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com