Inkjet textile printing equipment

A textile and printing technology, which is applied in the field of inkjet textile printing equipment, can solve problems such as the influence of cloth spraying, the inability to tighten the fabric, and the wrinkles of cloth spraying, so as to overcome existing defects, improve printing quality, and achieve good use effects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

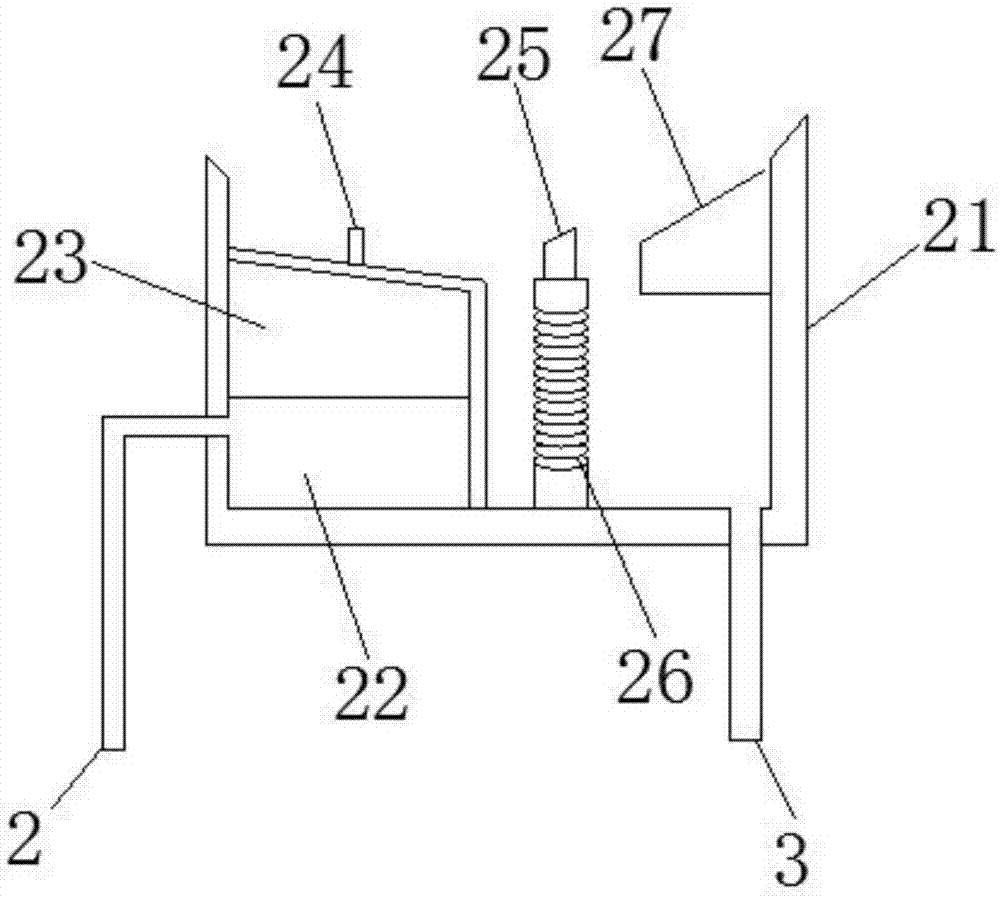

[0021] As an embodiment of the present invention, the cleaning unit 21 includes a water tank 22, a high-pressure pump 23, a nozzle 24, a scraper 25, a telescopic spring 26, and a dryer 27. The bottom side of the cleaning unit 21 is equipped with a water tank 22, so A high-pressure pump 23 is installed on the upper part of the water tank 22, and a nozzle 24 is installed on the upper part of the high-pressure pump 23. A scraper 25 is installed on one side of the water tank 22, and a telescopic spring 26 is installed on the lower part of the scraper 25. The scraper 25 A dryer 27 is installed on one side. In this technical solution, the cylinder 8 is cleaned by high-pressure water, and then the water on the cylinder is removed by the scraper 25, so that the subsequent dryer 27 can quickly dry the cylinder 8, and the purpose of rapid cleaning of the cylinder 8 is realized.

[0022] As another embodiment of the present invention, the cleaning unit 21 includes a collection box 31, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com