Carrying frame for finished products in glass manufacturing process

A technology for glass manufacturing and placing racks, which is applied to the packaging of vulnerable items, types of packaged items, rigid containers, etc., and can solve problems such as long cost, laborious, and cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

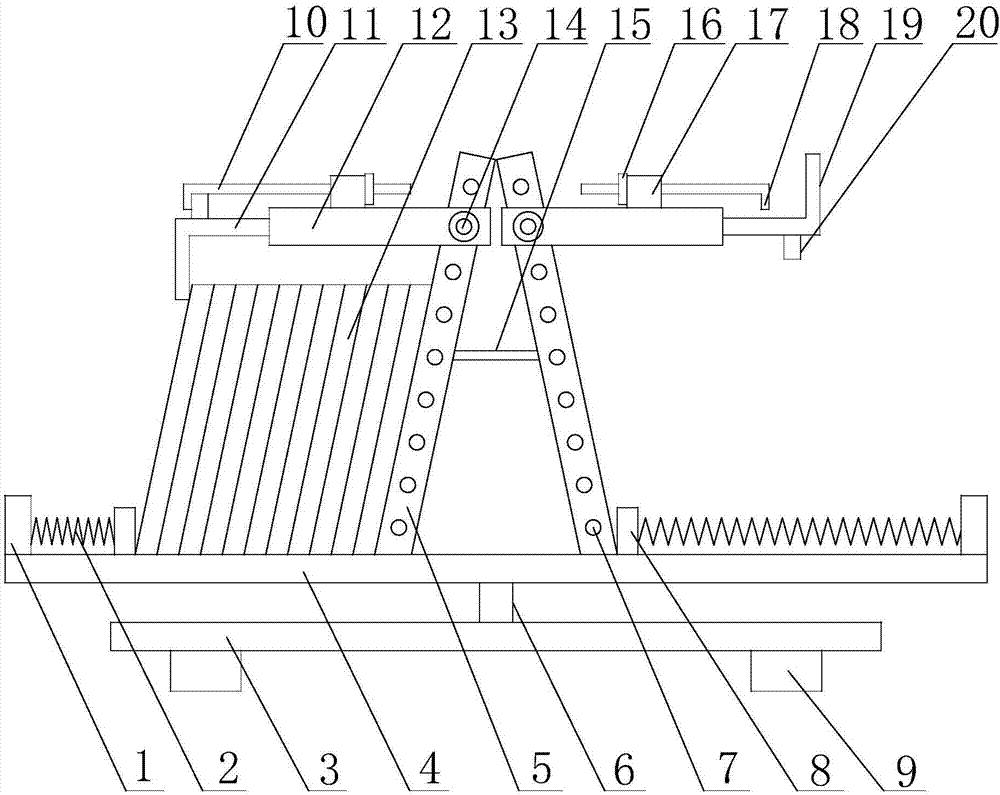

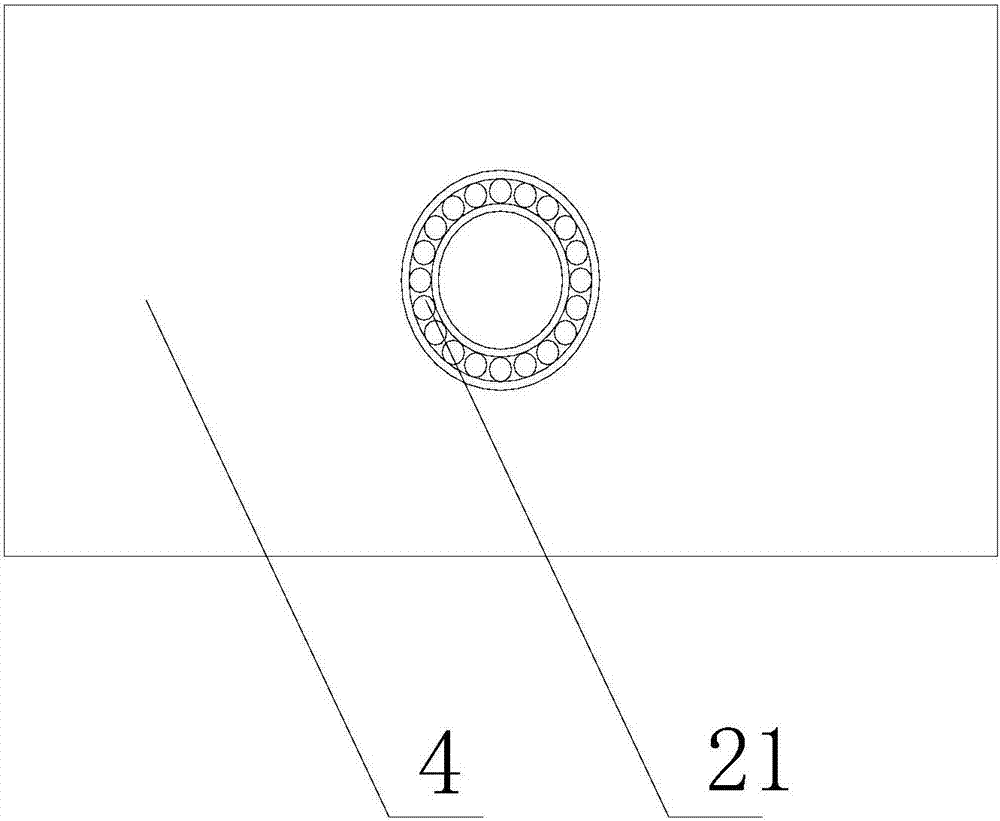

[0024] Such as figure 1 , figure 2 As shown, the shelf for placing finished products in the glass manufacturing process of the present invention includes a base 3 and two shovels 9 arranged at the bottom of the base 3, the shovels 9 are convenient for forklifts to carry the base 3, and the base 3 The top is provided with a support shaft 6, the support shaft 6 is located at the central position of the base 3, the support shaft 6 is provided with a bearing 21, the bearing 21 is matched with the support shaft 6, the bearing 21 is sleeved on the support shaft 6, and the bearing 21 can be mounted on the support shaft 6. Rotate on the support shaft 6, the bearing 21 is provided with a support plate 4, when the bearing 21 rotates, the support plate 4 can rotate together with the bearing 21, the top of the support plate 4 is provided with two baffle plates 5, the baffle plate 5 are respectively located on both sides of the axis of the support plate 4, and reinforcing ribs 15 are pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com