A Deformation Method to Reduce the Grade of Ribbon Carbide in GCR15 Bearing Steel

A technology of banded carbide and bearing steel, which is applied in the field of deformation technology of bearing steel, can solve the problem of few deformation studies, and achieve the effect of improving banded carbide.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] This embodiment is a deformation method for reducing the level of GCr15 bearing steel strip carbides, comprising the following steps:

[0022] (1) Electromagnetic stirring is adopted in the molten steel continuous casting stage, and high-temperature annealing is adopted after continuous casting. The high-temperature annealing temperature is 1220 ° C, and the holding time is 120-180min;

[0023] (2) After high-temperature annealing, the billet is rolled and opened into a cylindrical billet or square billet;

[0024] (3) The steel billet is formed by forging or rolling deformation method, the deformation temperature is 800 ℃, and the deformation amount of the billet is 40%.

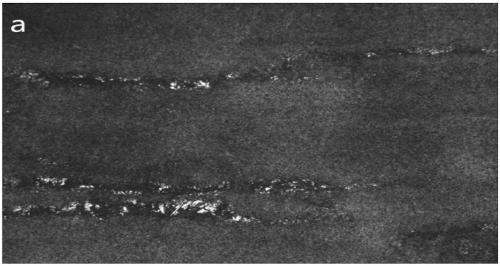

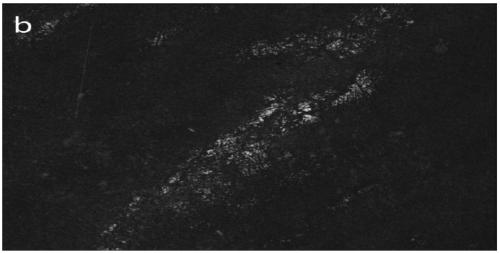

[0025] figure 1 It is the metallographic structure picture that present embodiment 1 obtains under 800 DEG C deformation temperature, figure 2 It is the metallographic structure picture at the deformation temperature of 850°C, figure 2 It is the metallographic structure picture obtained at the d...

Embodiment 2

[0027] This embodiment is a deformation method for reducing the level of GCr15 bearing steel strip carbides, comprising the following steps:

[0028] (1) The molten steel continuous casting stage adopts electromagnetic stirring, and adopts high-temperature annealing after continuous casting. The high-temperature annealing temperature is 1220 ° C, and the holding time is 120 min;

[0029] (2) After high-temperature annealing, the billet is rolled and opened into a cylindrical billet or square billet;

[0030] (3) The steel billet is formed by forging or rolling deformation method, the deformation temperature is 780 ℃, and the deformation amount of the billet is 30%.

Embodiment 3

[0032] This embodiment is a deformation method for reducing the level of GCr15 bearing steel strip carbides, comprising the following steps:

[0033] (1) Electromagnetic stirring is adopted in the molten steel continuous casting stage, and high-temperature annealing is adopted after continuous casting. The high-temperature annealing temperature is 1220 ° C, and the holding time is 180 min;

[0034] (2) After high-temperature annealing, the billet is rolled and opened into a cylindrical billet or square billet;

[0035] (3) The steel billet is formed by forging or rolling deformation method, the deformation temperature is 820 ℃, and the deformation amount of the billet is 50%.

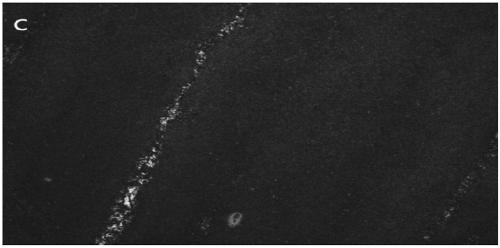

[0036] Figure 4 It is the metallographic structure picture under 25% deformation, Figure 5 It is the metallographic picture of the present embodiment 3 under 50% deformation. It can be seen from the comparison of the figures that the present invention can effectively reduce the level of GCr15 bande...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com