Construction method of high-speed railway overhead line support column foundation structure

A basic structure and construction method technology, applied in basic structure engineering, construction and other directions, can solve the problems of no proposed construction method, large environmental pollution and large impact of excavation, and achieve easy popularization and use, convenient and efficient construction, and foundation pit excavation. less digging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further explained below in conjunction with the drawings and embodiments:

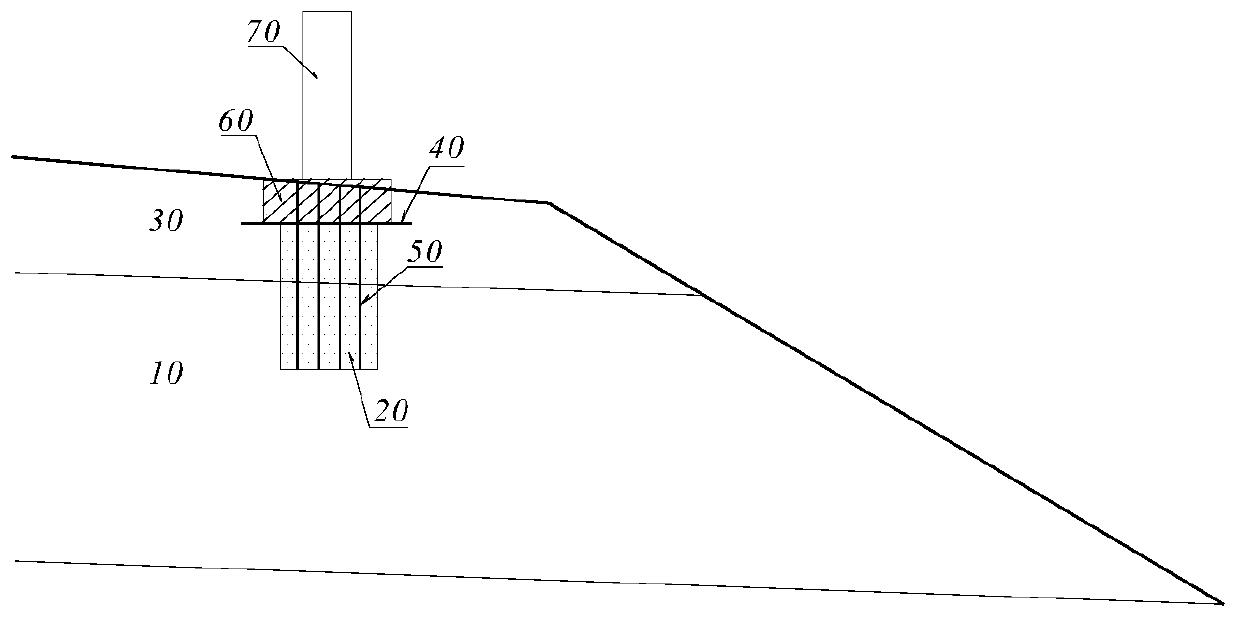

[0030] Reference figure 1 , The construction method of a high-speed railway catenary pillar foundation structure provided by the present invention includes the following steps:

[0031] ① Fill the lower part of the subgrade 10 in layers to the elevation position of the bottom of the catenary pillar foundation;

[0032] ②Continue to fill up the subgrade subgrade 10 and subgrade surface structure 30 above the bottom elevation of the catenary pillar foundation in layers, and fill the corresponding position of the catenary pillar foundation with water-permeable filler to form the water-permeable filler material 20 until the subgrade surface structure 30 20-30cm below the top surface;

[0033] ③Lay a layer of composite geomembrane 40 on the top of the water-permeable filling material 20, the size of the composite geomembrane 40 is larger than that of the contact net pillar foun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com