Automatic cocoon cooking device

An automatic cocoon cooking technology, which is applied in silk fiber production, textiles and papermaking, and mechanical processing, can solve the problems of inconvenient fishing of cocoons, affecting the quality of cocoons, and incomplete soaking of cocoons, so as to improve the efficiency of cocoon cooking and reduce the Labor intensity, the effect of ensuring the quality of cooking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

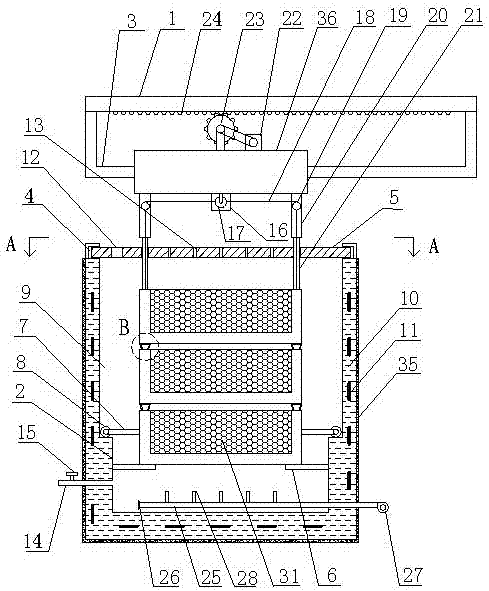

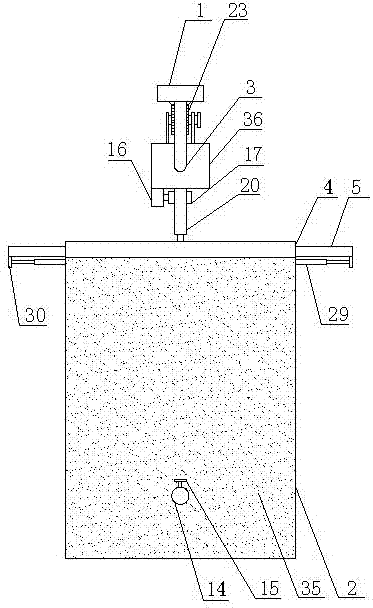

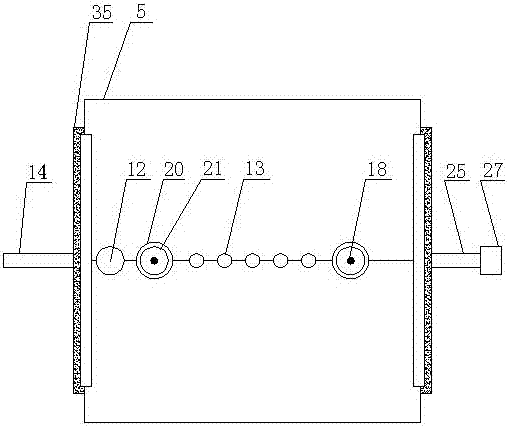

[0025] Such as Figure 1 to Figure 5 As shown, an automatic cocoon cooking device includes a support plate 1 and a cocoon cooking tank 2 with a rectangular structure, a slide bar 3 is provided at the bottom of the support plate, and a slide block 36 and a drive mechanism for driving the slide block to move are provided on the slide bar. The driving mechanism for slider movement includes travel motor 22, gear 23 and tooth pattern 24. The gear is installed above the slider for rotation. The output shaft of the travel motor is connected to the gear. The gear meshes with the gear at the bottom of the support plate, and the travel motor drives the gear to rotate. , because the gear meshes with the tooth pattern, the slider can move back and forth along the slider. The cocoon cooking tank is located below the slider, and a slot 4 is provided at the top, and a cover plate 5 and a cover plate opening are installed in the slot. Closing mechanism, the cover plate is formed by splicing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com