Energy-saving door and window profile surface transfer printing technique

A door and window profile and profile technology, which is applied in transfer printing, rotary printing machine, printing, etc., can solve the problems of high quality adhesive tape, inability to recycle, and high production cost, so as to improve the transfer printing effect and avoid Waste, the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

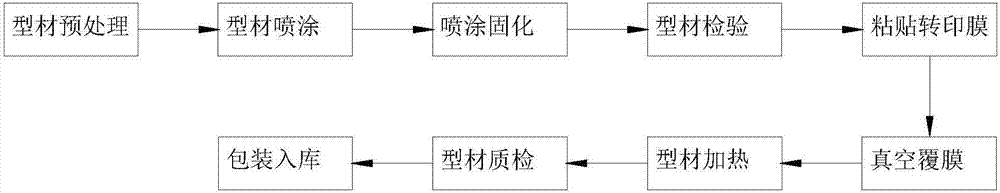

[0027] see figure 1 , the present invention provides a technical solution: comprising the following steps:

[0028] Step 1: Profile pretreatment: Cut and polish the profile according to the user's needs, and clean the profile surface;

[0029] Step 2: Profile spraying: Concentrate and evenly spray the pretreated profiles;

[0030] Step 3: Spraying and curing, performing curing operation on the profile after spraying;

[0031] Step 4: Profile inspection. For profiles that have been sprayed and cured, inspectors inspect the profiles to remove defective products that are deformed and incompletely sprayed;

[0032] Step 5: Paste the transfer film, wrap the transfer surface of the transfer film on the outer surface of the profile, install it on the profile with three high-temperature-resistant rubber rings, and fix the transfer film on the surface of the profile;

[0033] Step 6: Vacuum coating, put the profile wrapped with the transfer film into the film sleeve, and use the air...

Embodiment 2

[0046] Including the following steps:

[0047] Step 1: Profile pretreatment: Cut and polish the profile according to the user's needs, and clean the profile surface;

[0048] Step 2: Profile spraying: Concentrate and evenly spray the pretreated profiles;

[0049] Step 3: Spraying and curing, performing curing operation on the profile after spraying;

[0050] Step 4: Profile inspection. For profiles that have been sprayed and cured, inspectors inspect the profiles to remove defective products that are deformed and incompletely sprayed;

[0051] Step 5: Paste the transfer film, wrap the transfer surface of the transfer film on the outer surface of the profile, install it on the outer surface of the profile with a high temperature resistant rubber ring, and fix the transfer film on the surface of the profile;

[0052] Step 6: Vacuum coating, put the profile wrapped with the transfer film into the film sleeve, and use the air pump to extract the air in the film sleeve, so that t...

Embodiment 3

[0064] Including the following steps:

[0065] Step 1: Profile pretreatment: Cut and polish the profile according to the user's needs, and clean the profile surface;

[0066] Step 2: Profile spraying: Concentrate and evenly spray the pretreated profiles;

[0067] Step 3: Spraying and curing, performing curing operation on the profile after spraying;

[0068] Step 4: Profile inspection. For profiles that have been sprayed and cured, inspectors inspect the profiles to remove defective products that are deformed and incompletely sprayed;

[0069] Step 5: Paste the transfer film, wrap the transfer surface of the transfer film on the outer surface of the profile, use two high-temperature-resistant rubber rings to install on both ends of the profile, and fix the transfer film on the surface of the profile;

[0070] Step 6: Vacuum coating, put the profile wrapped with the transfer film into the film sleeve, and use the air pump to extract the air in the film sleeve, so that the fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com