High-temperature high-pressure multi-compound sealed casing head

A high-temperature, high-pressure, composite sealing technology, which is applied in sealing/isolation, wellbore/well components, earthwork drilling and production, etc., can solve the problems of unsafe and reliable use, poor sealing effect, etc., and achieve safe and reliable use and prevent fluid leakage The effect of channeling and reducing the cost of production operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

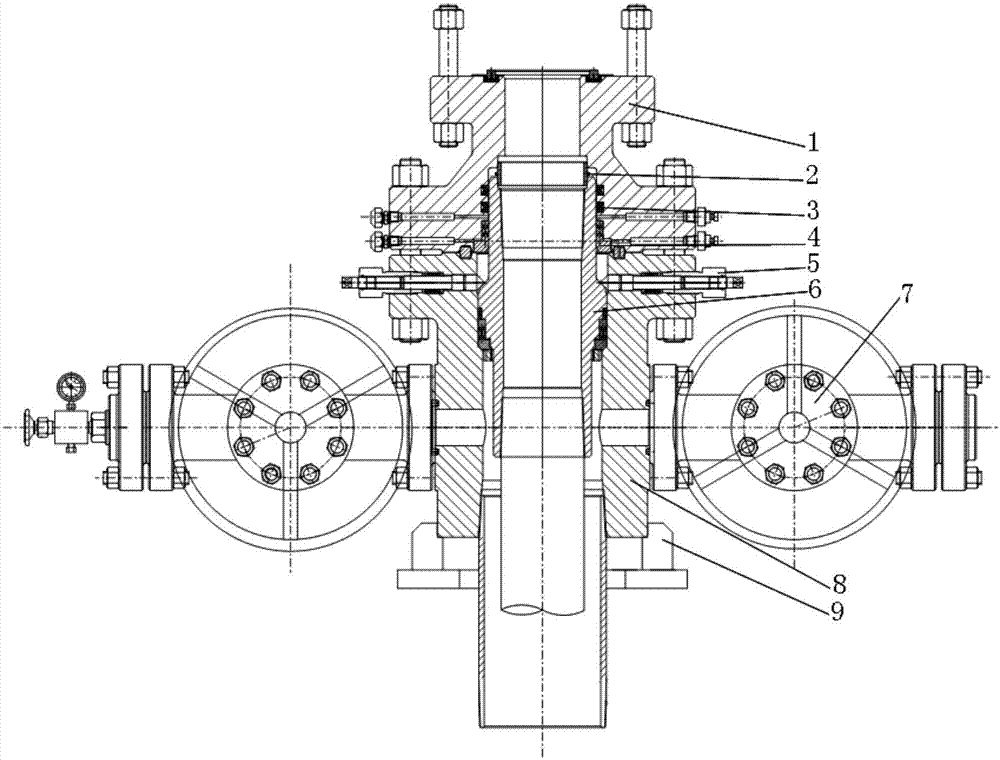

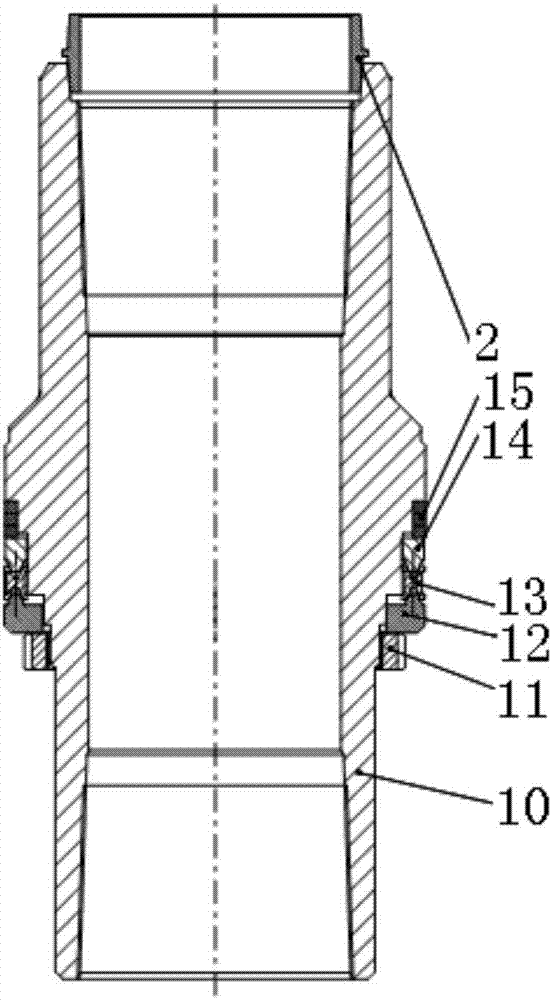

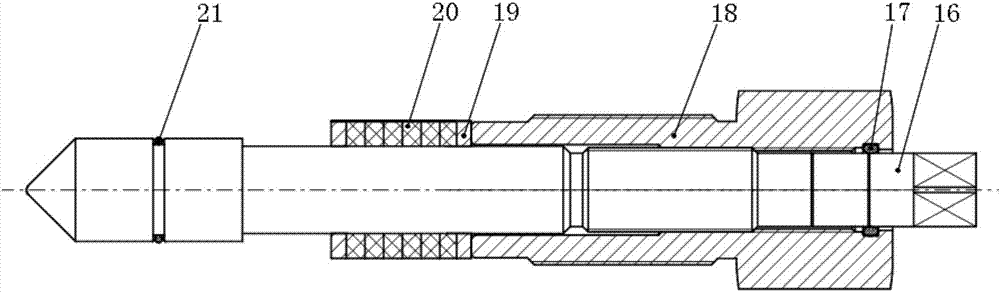

[0020] Such as figure 1 , figure 2 , image 3 As shown, a high temperature and high pressure multiple compound sealed casing head includes a cover flange 1, a high temperature and high pressure flat valve 7 and a casing head body 8; the upper end of the casing head body 8 is connected to the cover flange 1 and the casing head body 8 Both sides are connected with high-temperature and high-pressure flat valve 7, a mandrel hanger assembly 6 is installed inside the casing head body 8, and the mandrel hanger assembly 6 includes a mandrel hanger main body 10, and a mandrel hanger main body A positioning metal sealing steel ring 2 is arranged between the upper end of 10 and the cover flange 1, and an auxiliary non-metallic sealing ring 3 and an upper metal sealing assembly 4 are arranged between the outer wall of the upper end of the mandrel hanger main body 10 and the inner wall of the cover flange 1, A positioning anti-rotation sealing device 5 is arranged on the side wall of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com