Dust removal system of stepped atomizing sub-region of fully mechanized excavation face

A technology of dust removal system and working face, which is applied in dust prevention, safety devices, mining equipment, etc. It can solve problems that affect the driving efficiency, deteriorate the working environment of the driving face, and water in the working area, so as to improve the effect of dust isolation and dust reduction, and slow down The effect of moving speed with the wind and increasing the jet speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

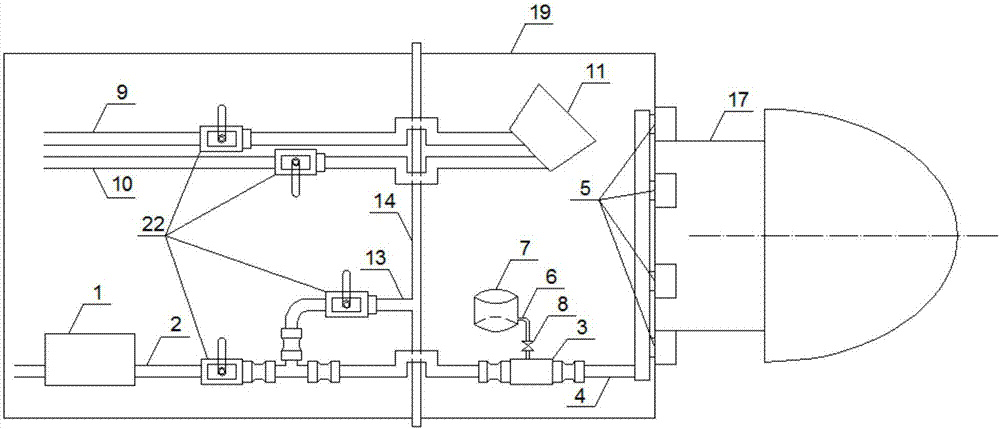

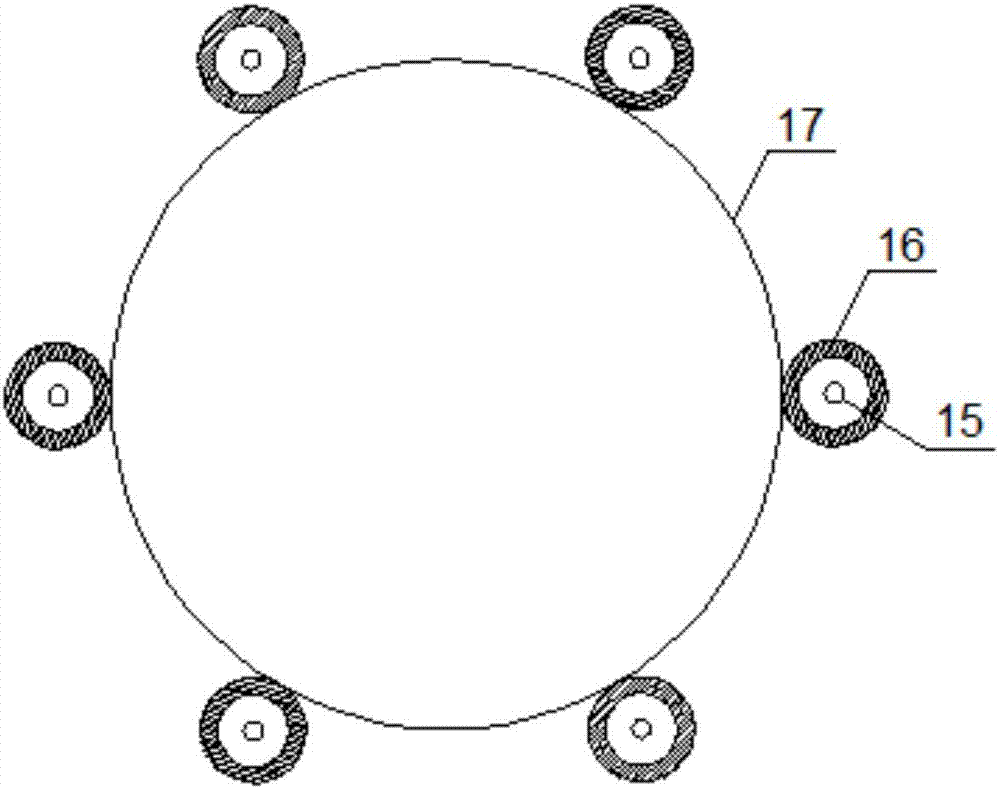

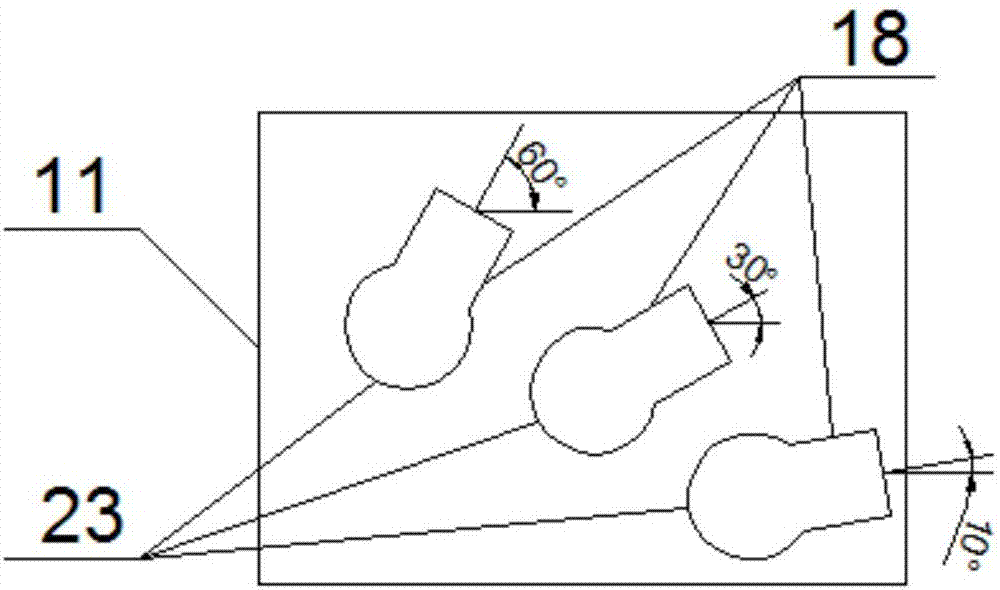

Embodiment 1

[0026] Embodiment 1: as Figure 1-4 As shown, this embodiment provides a stepped atomization partition dust removal system for fully mechanized excavation working faces, including a high-pressure jet atomization dust suppression module, an air atomization dust suppression module, a dynamic pressure atomization dust isolation module; a high-pressure jet atomization dust suppression module Including booster pump 1, high-pressure water pipe 2, dust suppressant automatic adding device 3, dust suppressant solution delivery pipe 4, negative pressure secondary atomization dust suppression device 5, and dust suppressant automatic adding device 3, which are connected in sequence The pipe 6 communicates with the dust suppressant container 7, and the suction pipe 6 is provided with a first regulating valve 8.

[0027] The air atomization dust reduction module includes an air atomization dust reduction device 11 connected with the pressure air pipe 9 and the static pressure water pipe 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com