A method for measuring the fillet radius of shaft parts with multiple fillets on the end face

A technology for shaft parts and fillet radius, which is applied in the field of measuring the fillet radius of shaft parts with multiple fillets on the end face, can solve the problems of unqualified, greatly affecting the accuracy of test results, and the inability to express the measured value, etc., to achieve good results The effect of reliability and measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

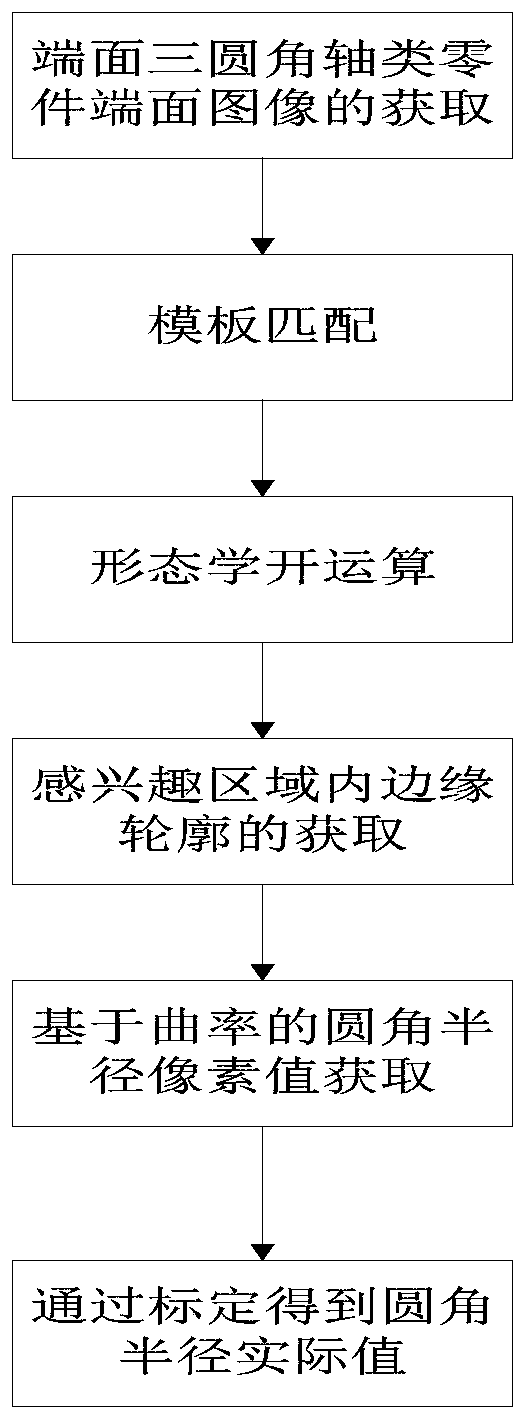

[0042] The invention establishes the mapping relationship between the end face image of the shaft part with multi-rounded corners on the end face to be detected and the template image through template matching, and then eliminates the edge burr interference of the shaft part with multi-rounded corners on the end face to be detected through the morphological opening operation, and then through edge detection The operator and the eight-neighborhood boundary tracking algorithm obtain the contour coordinates of shaft parts with multiple rounded corners on the end face in the region of interest, and obtain the division points of each rounded corner area through discrete point curvature calculations, and obtain each rounded corner by least squares circle fitting The pixel value of the radius is finally calibrated to obtain the actual value o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com