A secondary structure of a permanent magnet linear motor and its potting tooling and potting process

A permanent magnet linear motor and secondary structure technology, applied in electromechanical devices, manufacturing motor generators, electrical components, etc., can solve problems such as scrapping, reducing colloid strength, and poor sealing of internal parts, achieving cost reduction and good protection , The effect of compression potting hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

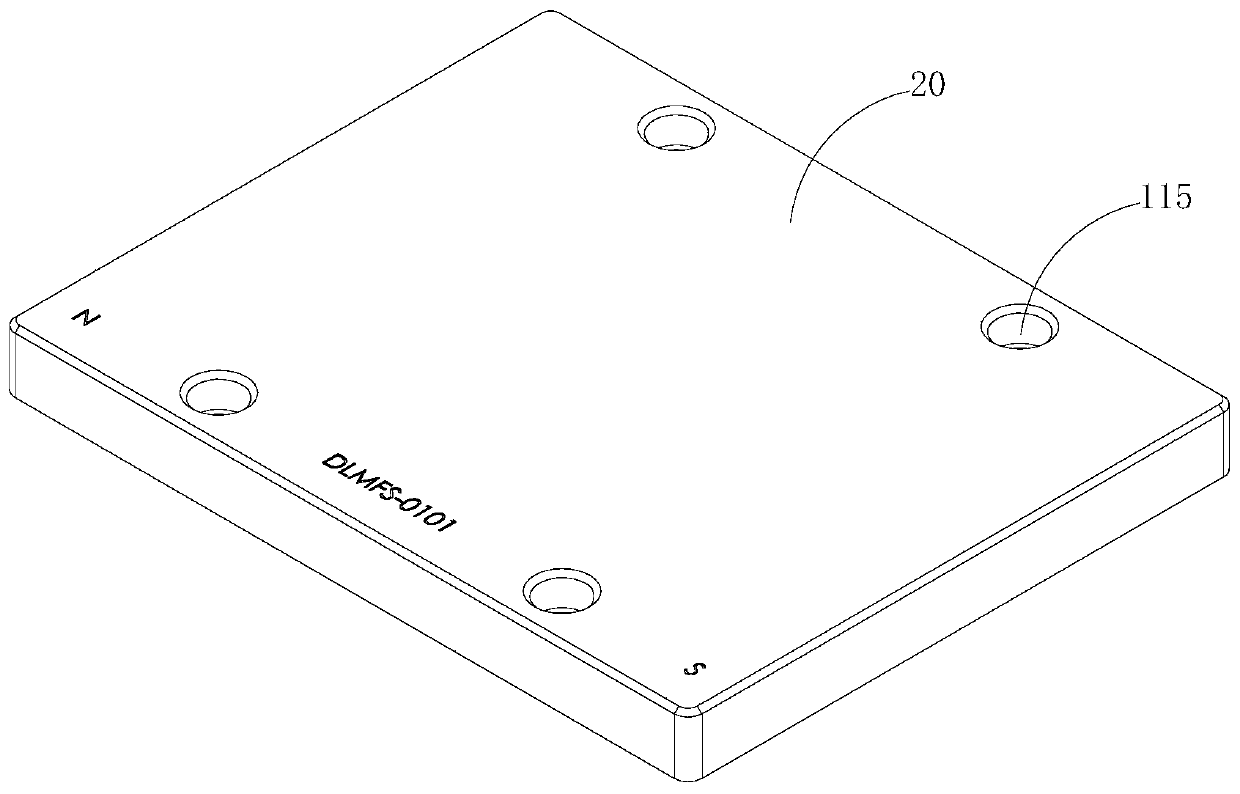

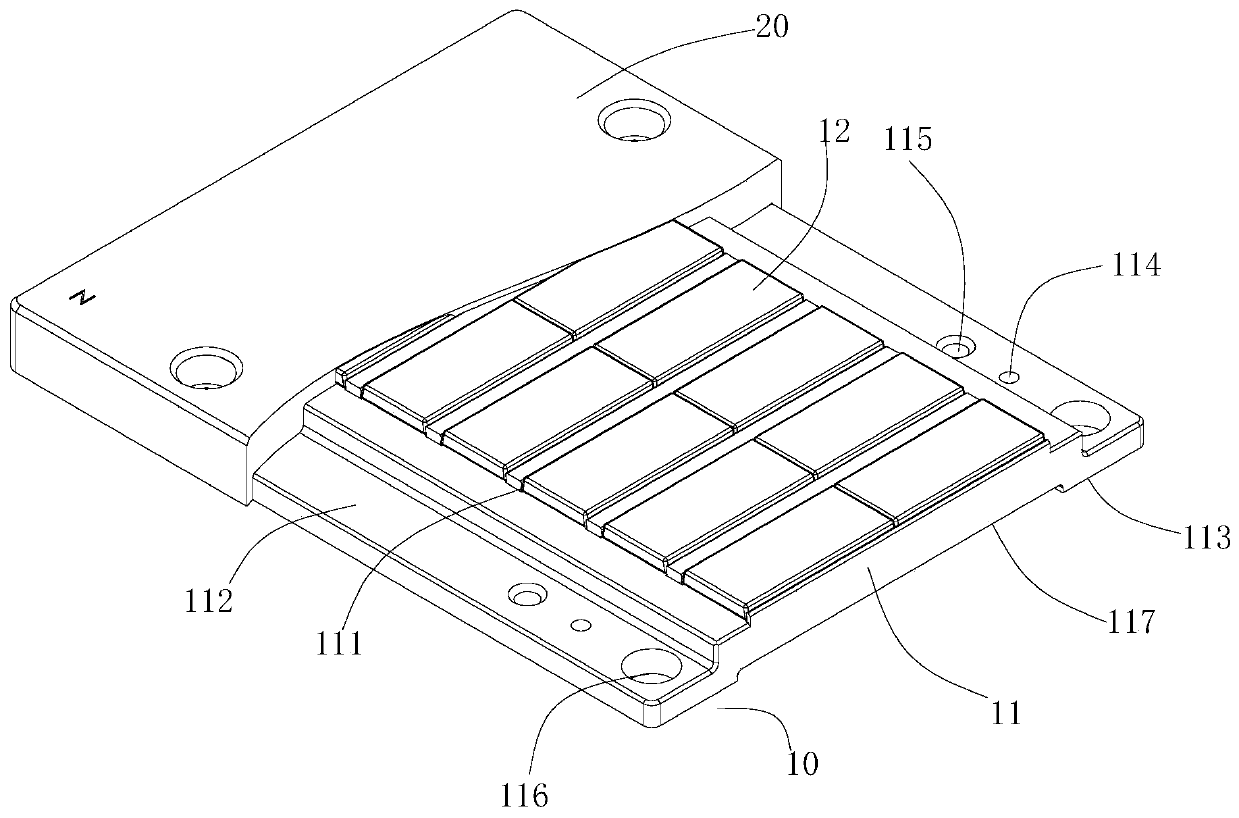

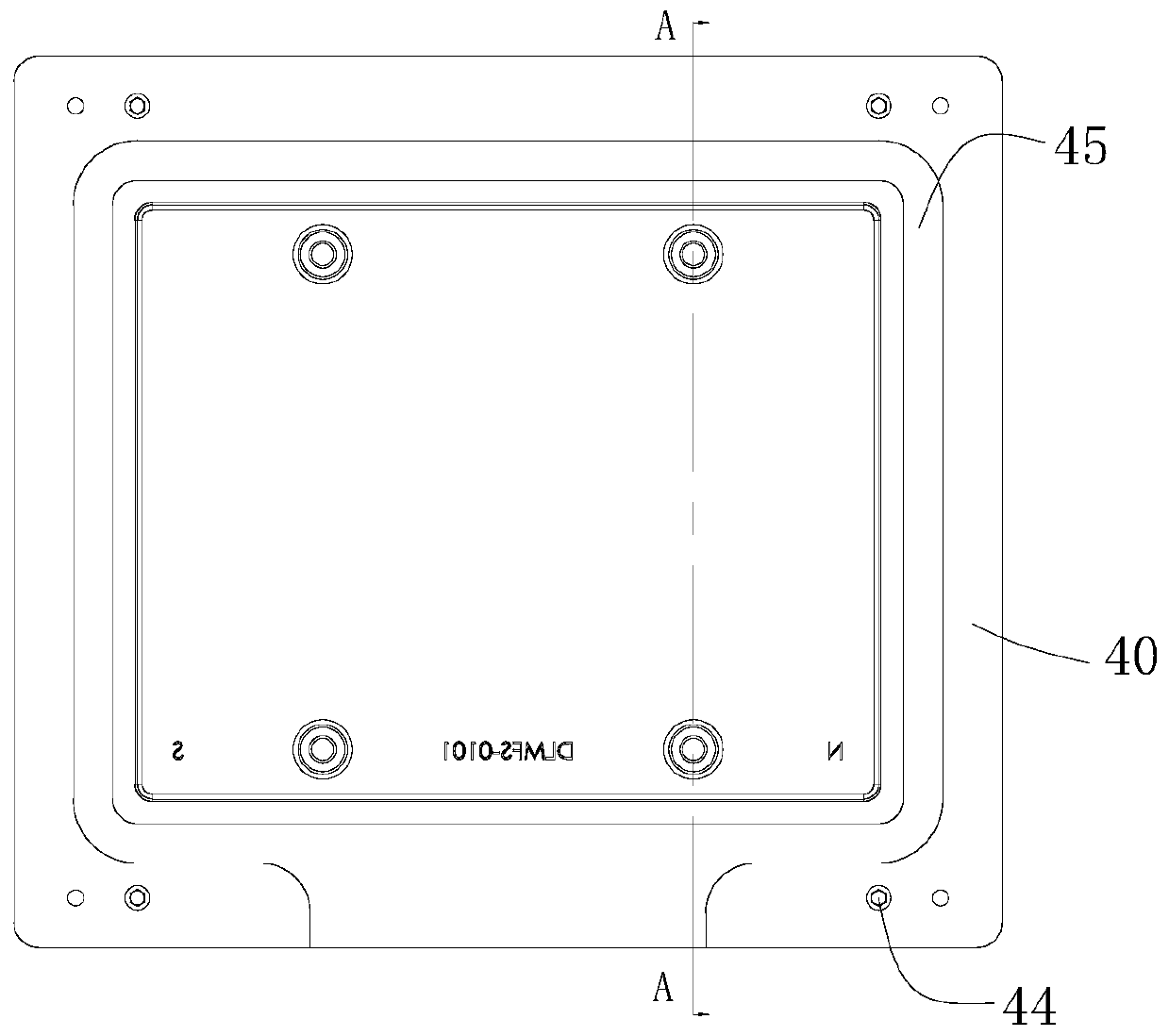

[0061] refer to Figure 1-2 , a permanent magnet linear motor secondary structure, including a secondary body 10; the secondary body 10 includes a magnetic mounting plate 11 and a permanent magnet 12; the upper surface of the magnetic mounting plate 11 is provided with several regularly arranged grooves 111 Each groove 111 is embedded with a permanent magnet 12; the magnetically permeable mounting plate 11 is provided with mounting parts 112 distributed on both sides of the groove 111, and the lower surface of the magnetically permeable mounting plate corresponds to the position of the mounting part 112. Surface 113, by figure 2 It can be seen that, taking the height direction of the magnetically conductive mounting plate 11 as a reference direction, the upper surface of the mounting portion 112 is lower than the upper surface of the permanent magnet 12 arranged in the groove, and the lower surface of the magnetically conductive mounting plate 11 is lower than the upper surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com