Gas intake system of atomic layer deposition device and method of gas intake system

A technology of atomic layer deposition and air intake system, which is applied in the direction of coating, gaseous chemical plating, metal material coating process, etc., can solve the problems of low utilization rate and low production efficiency of atomic layer deposition equipment, and achieve the improvement of utilization rate , Improve efficiency and reduce idle time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

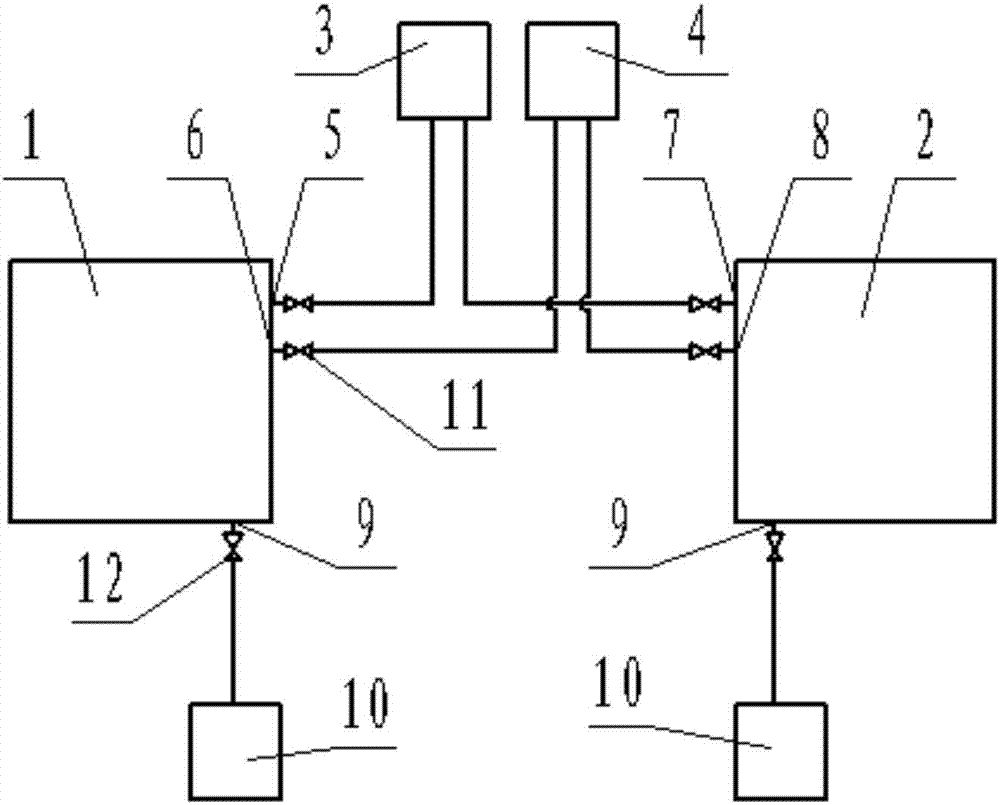

[0030] Embodiment 1: as figure 1 As shown, this embodiment provides an air intake system of an atomic layer deposition apparatus, which includes a first reaction chamber 1 and a second reaction chamber 2 that are independent from each other. The first reaction chamber 1 is provided with a first air inlet 5 and a second air inlet 6, and the second reaction chamber 2 is provided with a third air inlet 7 and a fourth air inlet 8, and the first air inlet 5 A first gas source 3 is connected to the third air inlet 7 through a pipeline, and the first gas source 3 is used to supply gaseous organic sources (such as trimethylaluminum) to the first reaction chamber 1 and the second reaction chamber 2 . The second air inlet 6 and the fourth air inlet 8 are connected with a second gas source 4 by pipeline, and the second gas source 4 is used to supply gaseous water in the first reaction chamber 1 and the second reaction chamber 2, ( It can also match other gaseous organic sources as oxyg...

Embodiment 2

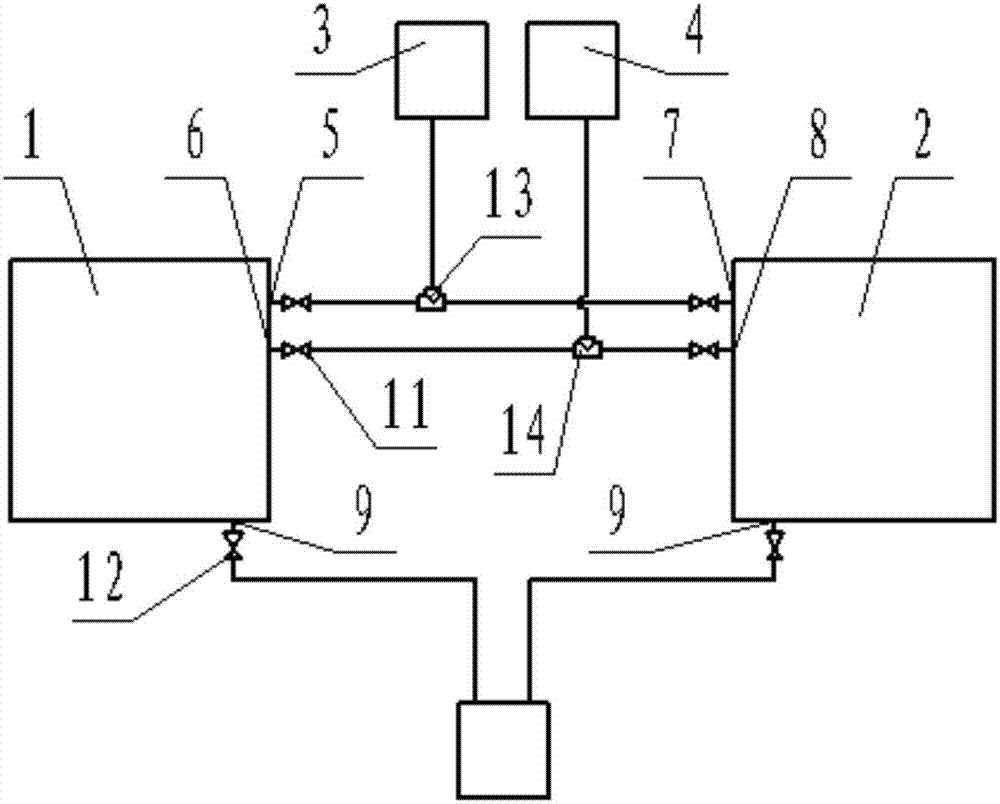

[0038] Embodiment 2: as figure 2 As shown, the difference between this embodiment and Embodiment 1 is that: the two exhaust ports 9 are connected to a vacuum pump 10 through pipelines, and the pipelines between the two exhaust ports 9 and the vacuum pump 10 are respectively provided with an exhaust switch valve. 12. The first air inlet 5, the third air inlet 7 and the first air source 3 are connected with a first three-way valve 13 through a pipeline, and the first air inlet 5 and the third air inlet 7 are connected to the first three-way valve 13. An intake switch valve 11 is respectively arranged between them. The second air inlet 6, the fourth air inlet 8 and the second air source 4 are connected with a second three-way valve 14 through pipelines, and the second air inlet 6 and the fourth air inlet 8 are connected with the second three-way valve 14 An intake switch valve 11 is respectively arranged between them.

[0039]In this embodiment, a three-way valve is used to c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com