Vessel

A technology for ships and bows, applied in the direction of hull, ship construction, hull design, etc., can solve the problems of large bow wave, large wave resistance, deck area limitation, etc., and achieve the effect of less energy consumption and less resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

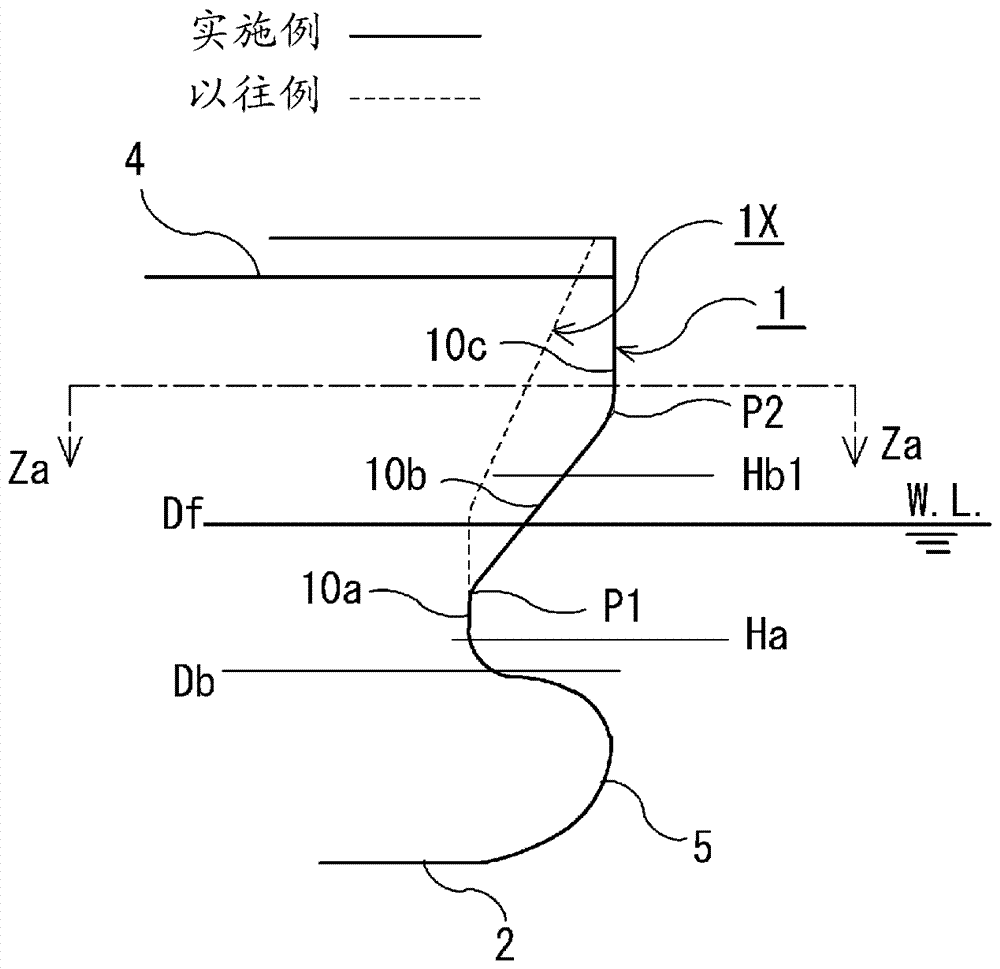

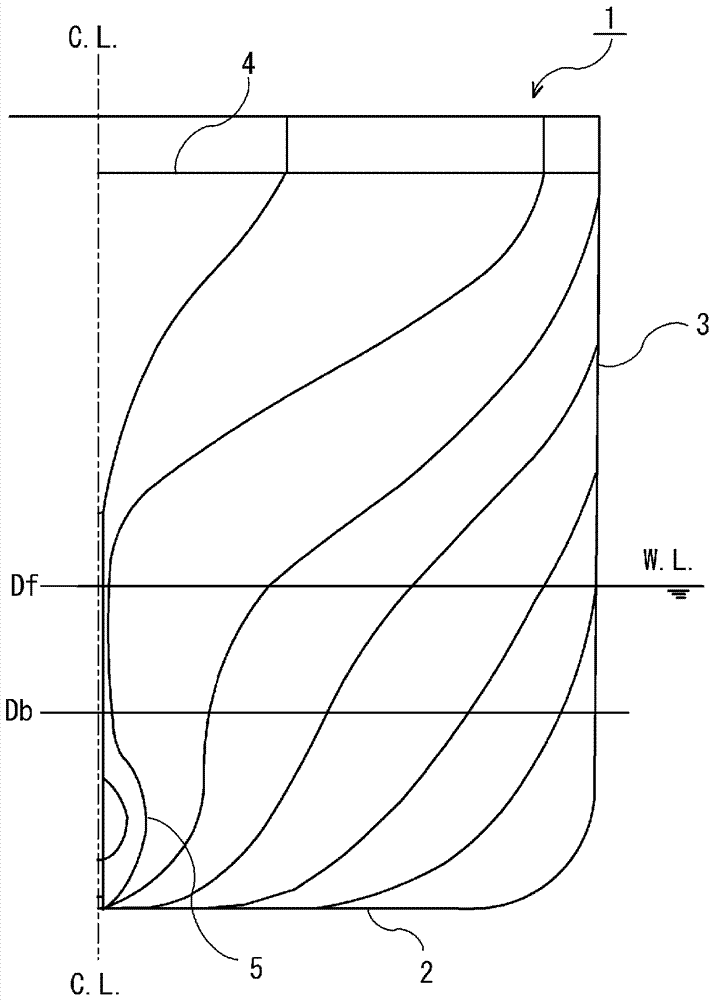

[0037] Hereinafter, a ship according to an embodiment of the present invention will be described with reference to the drawings. The ship of this embodiment is a displacement type ship, where the planned ship speed is Vs, the length between perpendiculars is Lpp, the profile is B, and the columnar coefficient of the front half of the hull is Cpf.

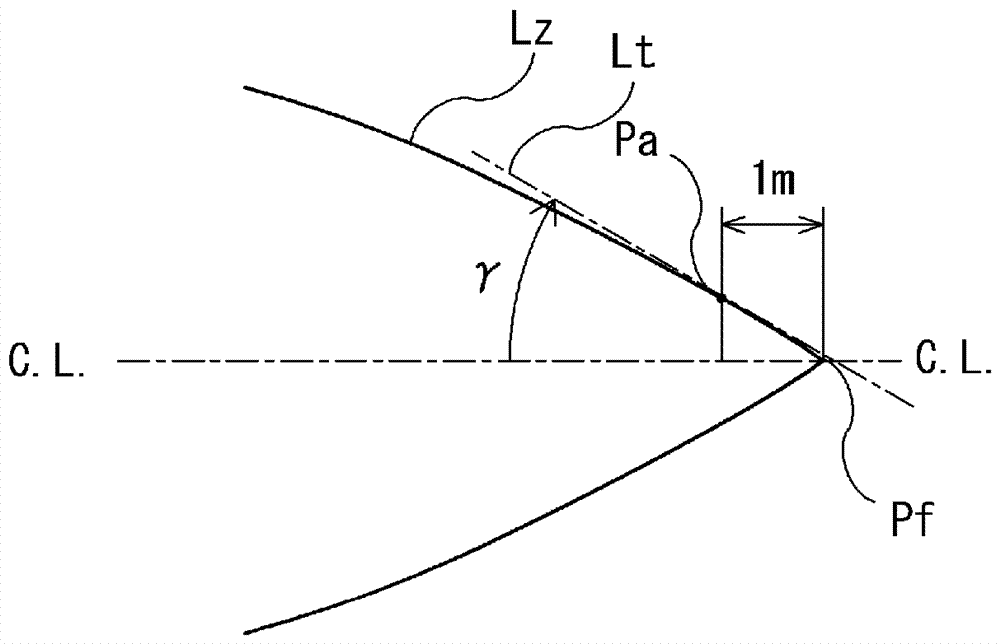

[0038] Under this condition, when the gravitational acceleration is set as g, according to ΔHm=V 2 The ΔHm calculated by / (2g) is set as the maximum water head height ΔHm, and the ΔHs calculated according to ΔHs=0.3×ΔHm is set as the reference water head height ΔHs. In addition, according to γs=tan -1 The angle γs calculated by [0.5×B / {(1-Cpf)×Lpp}] (°: degree) is set as the reference bow angle γs.

[0039] In addition, if figure 1 and figure 2 As shown, the ship 1 according to the first embodiment of the present invention is configured to have a bow bulb 5 below the light-load waterline Db, and set the range of "0<Rs<γs+15°" w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com