Bearing blank automatic turnover mechanism

A technology of automatic inversion and shaft blank, applied to conveyor objects, transportation and packaging, etc., can solve problems such as conveyor bumps, shaft blank deformation, conveyor impact, etc., to achieve no impact and bumps, improve continuity and The degree of automation, the effect of smooth and reliable flipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

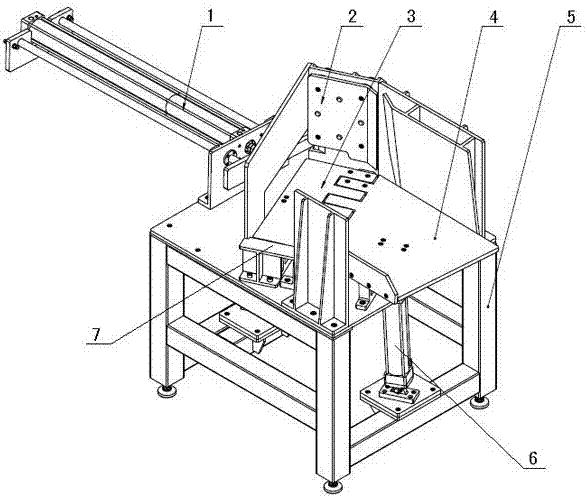

[0008] The present invention will be further described below in conjunction with the accompanying drawings.

[0009] The base 5 is welded with carbon steel sections, and the height-adjustable feet are installed at the bottom. Two flat plates on the base 5 are fixedly turning over push pedal 3 and turning over material receiving plate 4, and turning over pushing pedal 3 and turning over material receiving plate 4 lower ends are connected with turning cylinder 6 respectively.

[0010] The limit buffer plate 2 is connected to the support at the back by 4 groups of guide shafts and linear bearings, and 4 hydraulic buffers are fixed on the support, and the ends of the buffer are pushed against the back side of the limit buffer plate. In this way, when the shaft blank rolls and hits the limit buffer plate, the hydraulic buffer has just played the role of buffer limit.

[0011] The overturning push plate 3 and the overturning material receiving plate 4 are made of 304 stainless stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com