Method for improving conjugacy of looping cam mechanism of warp knitting machine

A technology of cam mechanism and conjugation, which is applied in the field of improving the conjugation of warp knitting machine knitting cam mechanism, and can solve the problems of operator skills, high experience requirements, heavy grinding workload, and long time-consuming, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

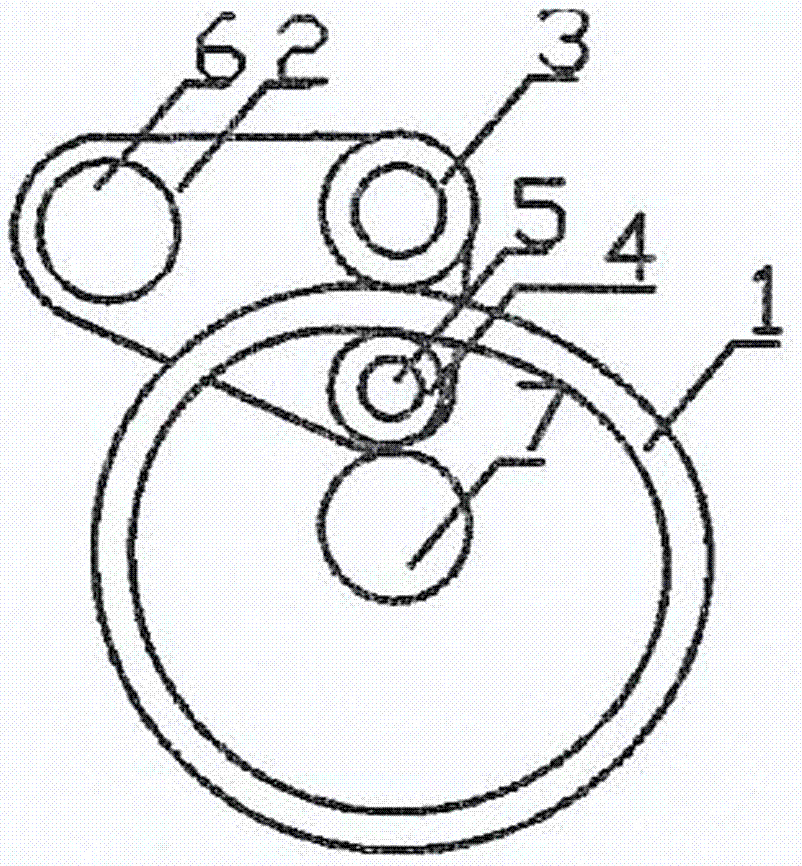

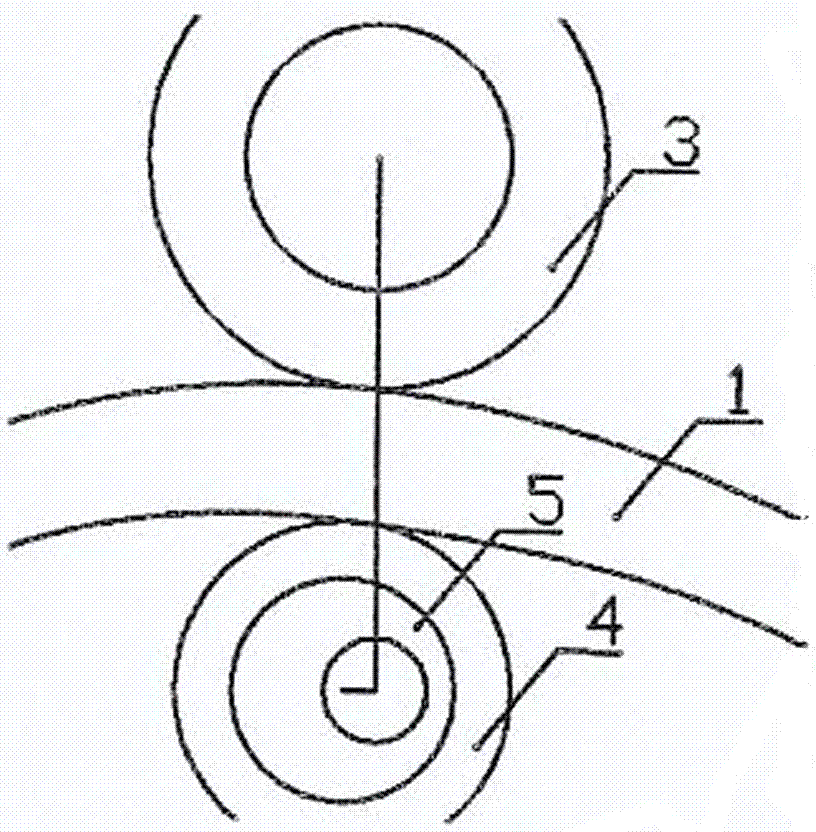

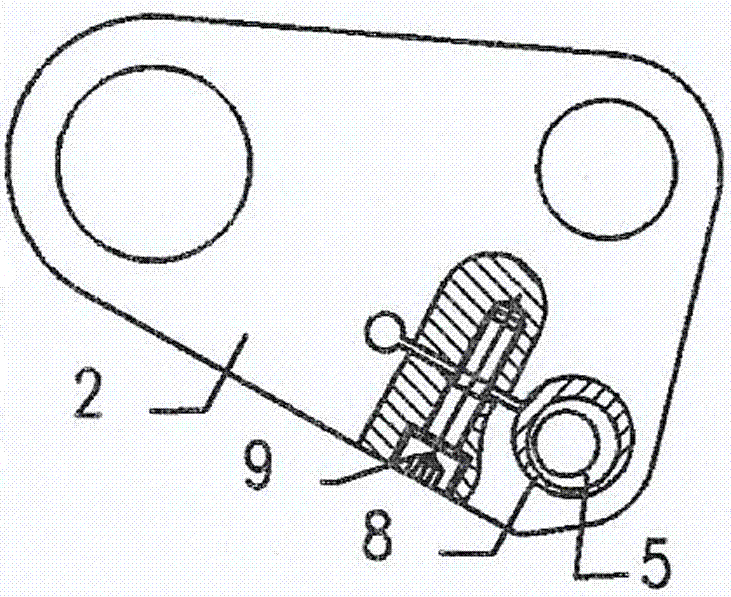

[0044] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

[0045] The method for improving the conjugation of the knitting cam mechanism of the warp knitting machine comprises the following steps:

[0046] 1. An eccentric sleeve 8 is added between the pendulum frame 2 and the eccentric mandrel 5 of the loop forming cam mechanism of the original warp knitting machine:

[0047] Through the joint adjustment of the eccentric sleeve 8 and the eccentric mandrel 5, the adjustment range is a torus, and it is possible to adjust to the optimum point. By adjusting the eccentric sleeve 8, the shafts 6 constraining the pendulum on the frame can be actually changed respectively. The difference in the distance from the center of the two rollers, so as to achieve the purpose of improving the conjugation of the cam mechanism;

[0048] Due to the processing error of related parts, the cam mechanism conjugation deviation is concentrated in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com