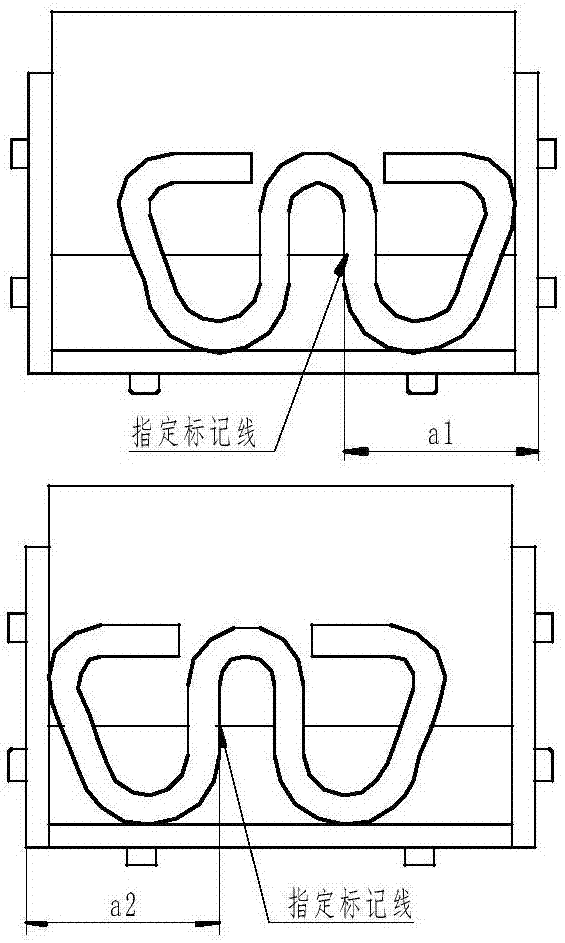

Omega-shaped sliding block type rapid inspection fixture for inspecting degree of symmetry of elastic strip and inspection method

A symmetry and slider-type technology, which is applied in angle/taper measurement and other directions, can solve problems such as inability to quickly detect and cumbersome inspection methods for symmetry indicators, and achieve the effect of simplifying the measurement process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

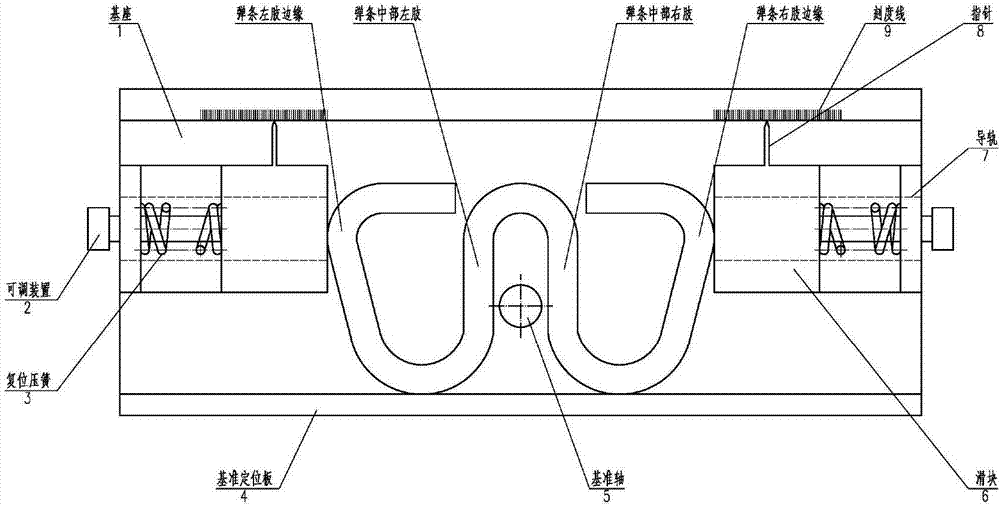

[0014] A kind of ω-type spring bar symmetry slider type quick checker, such as figure 2 As shown, it includes: base 1, adjustable device 2, return pressure spring 3, reference positioning plate 4, reference axis 5, slider 6, guide rail 7, pointer 8, scale line 9, etc., among which:

[0015] Base 1 is the bearing platform of all components;

[0016] The adjustable device 2 is installed on the carrying platform, and can adjust the initial positions of the left and right sliders;

[0017] The return compression spring 3 is a compression spring for the slider reset, and cooperates with the adjustable device to complete the calibration of the initial position of the slider and the automatic reset of the slider;

[0018] The reference positioning plate 4 is the positioning reference when the elastic bar is in place, and is fixed on the carrying platform;

[0019] The reference axis 5 is the positioning reference during the spring strip test, and is fixedly installed on the center...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com