Beverage preparation machine

A beverage preparation and beverage technology, applied in the field of beverage preparation machines, can solve the problems of scaling, short service life, affecting valve sealing, etc., and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

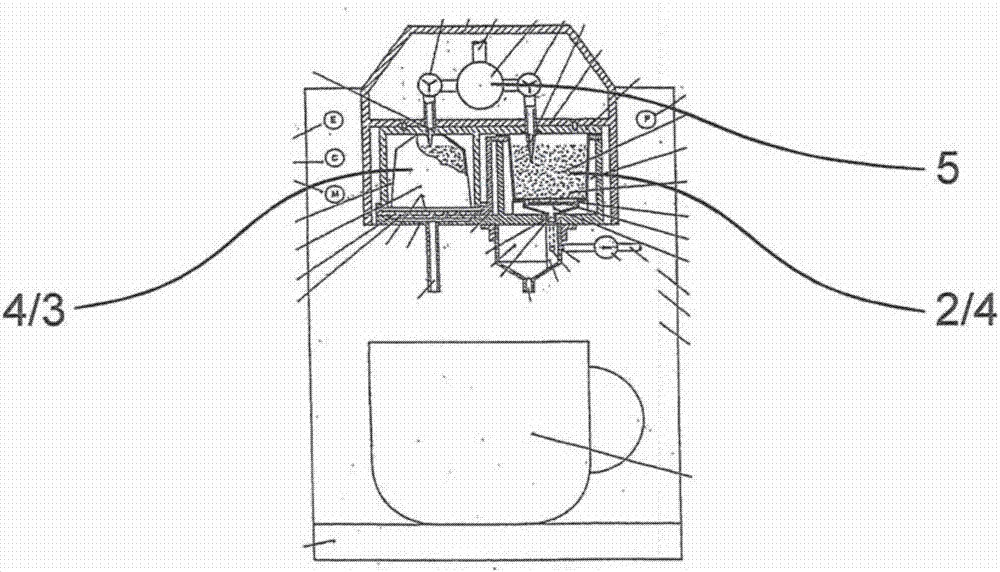

[0041] figure 1 A prior art beverage preparation machine with two brewing chambers 2 , 3 and a switching valve 5 is shown schematically. In each of the brewing chambers 2 , 3 is accommodated a capsule which is filled with a beverage base 4 . Both brewing chambers have injectors, which inject liquid into the respective brewing chamber or the respective capsule. The injector is connected to a switching valve 5 which controls the flow of water to the individual brewing chambers 2,3.

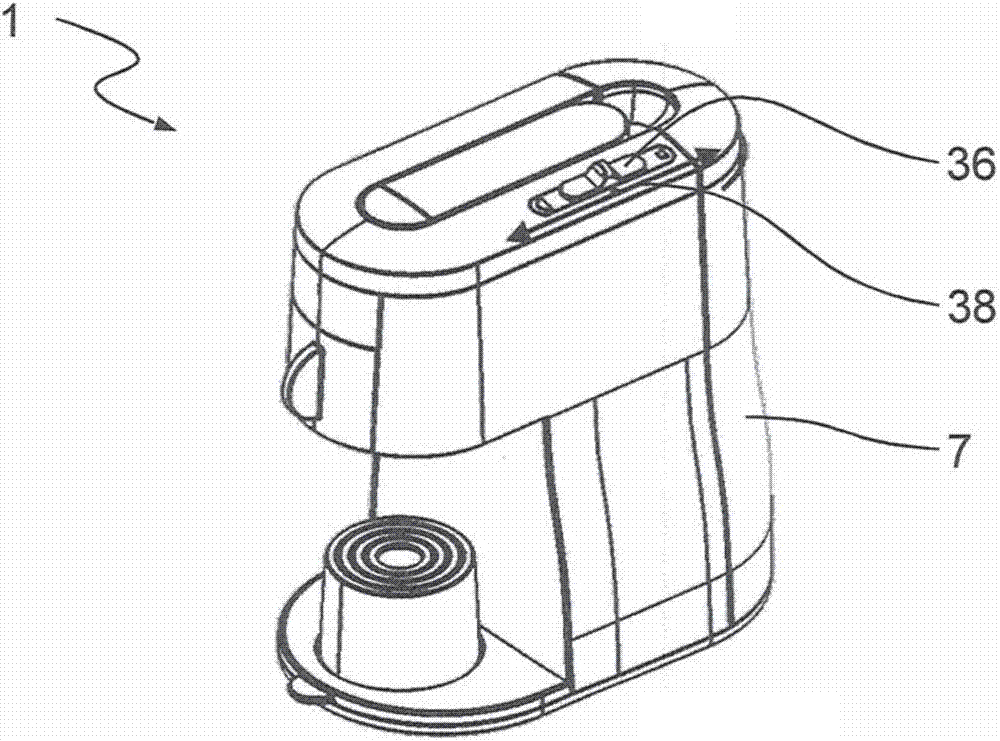

[0042] exist figure 2 The beverage preparation machine 1 according to the invention is shown in perspective view in FIG. Beverage preparation machine 1 as figure 1 There are two brewing chambers (not shown) that can be controlled individually as in the beverage preparation machine of the present invention. For this purpose, the beverage preparation machine 1 is provided with a control 36, by means of which the corresponding brewing chamber can be selected. In this case, the control element 36...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com