Device for force transfer between chassis frame and carriage body of a rail vehicle

A rail vehicle and chassis technology, applied in the direction of the device for lateral relative movement between the chassis and the bogie, can solve the problems of weakening the damping of the impact, reducing the comfort of the ride, increasing the weight, etc., achieving simple design, easy manufacturing, Minimize the effect of surface pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

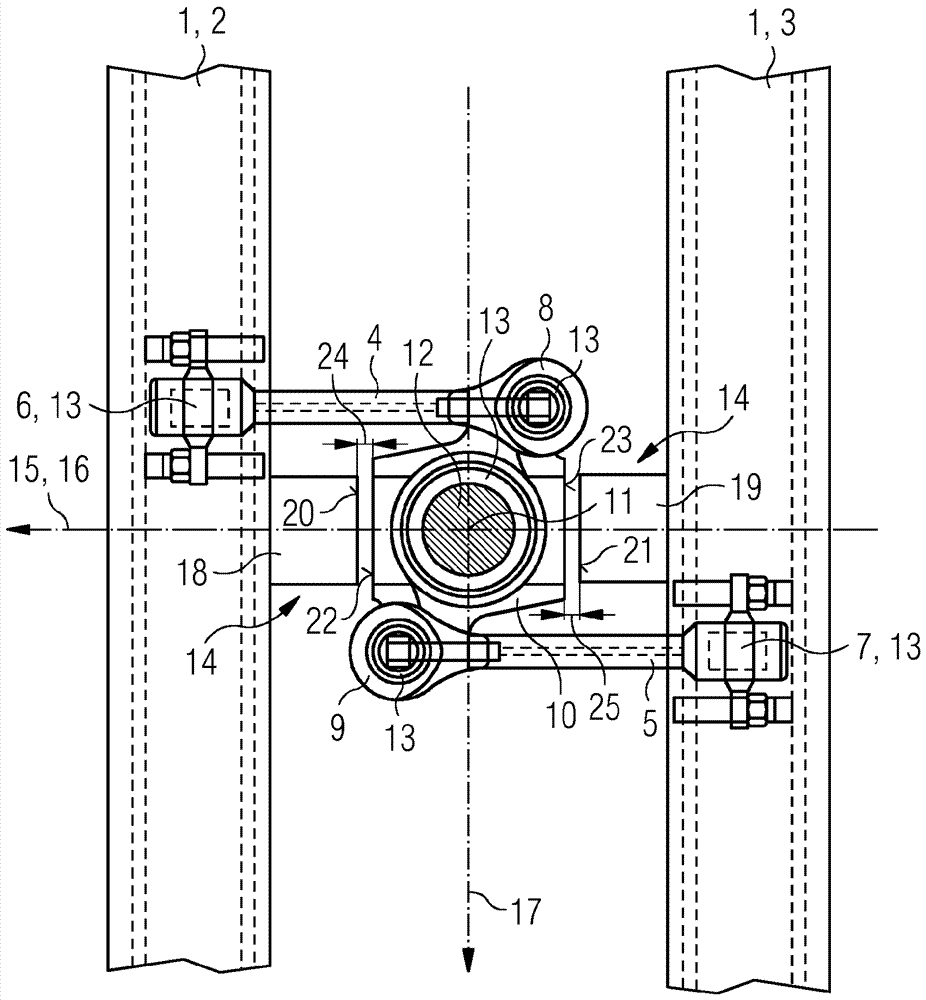

[0032] figure 1 A first transverse arm 2 and a second transverse arm 3 of the chassis frame 1 are shown, wherein the longitudinal members of the chassis frame 1 connecting the two transverse arms 2 , 3 are not shown. In this context, the transverse arms 2 , 3 extend parallel to the transverse direction 17 of the chassis frame 1 and are aligned symmetrically with respect to the longitudinal direction 16 perpendicular to the transverse direction 17 . In this context, the device for force transmission according to the invention between the chassis frame 1 and the carriage body comprises a first double-button link 4 and a second double-button link 5 as well as an intermediate connection point 11 yoke (joch)10.

[0033] The first double-button link 4 includes a first connection portion 6 and a second connection portion 8 , and is connected to the first cross arm 2 via the first connection portion 6 and to the yoke 10 via the second connection portion 8 . Similarly, the second dou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com