a mixer truck

A technology for mixing trucks and aggregates, which is applied to unloading devices, cement mixing devices, clay preparation devices, etc., can solve the problems of slowing down the construction progress, easy splashing of discharge materials, and high use costs, and achieves speeding up the construction progress. , Improve the discharge efficiency, improve the effect of feeding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

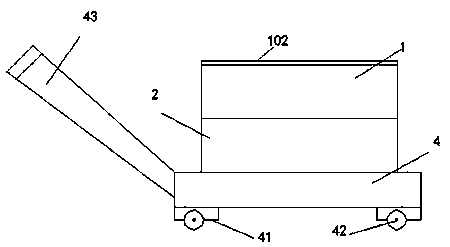

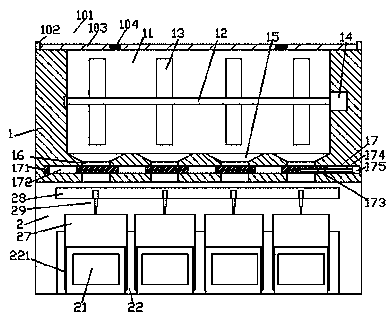

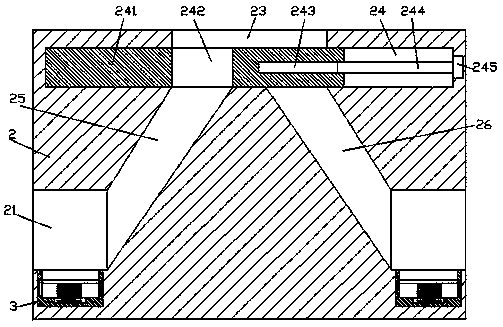

[0024] Such as Figure 1-Figure 6 As shown, a mixing cart of the present invention includes a mixing part 1, a feeding part 2 arranged at the bottom of the mixing part 1, and a frame body 4 arranged at the bottom of the feeding part 2. The bottom end surface of the material part 2 is fixedly connected with the top surface of the frame body 4, corner posts 41 are arranged on the four corners of the bottom of the frame body 4, and rollers 42 are provided at the bottom of each corner post 41, thereby facilitating movement or transportation , the left end surface of the frame body 4 is fixed with an oblique push handle 43, the mixing part 1 is provided with a silo 11, and the bottom of the silo 11 is provided with multiple groups of bucket-shaped grooves 15, and each bucket-shaped The bottom of the groove 15 is provided with a mouth 16, and the mouth 16 is provided with a first sliding groove 17 passing through the mouth 16 and extending to the left and right sides, and the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com