Spring fixing seat and spring test device using same

A technology of spring fixing seat and testing device, which is applied in the direction of measuring device, testing of mechanical parts, testing of machine/structural parts, etc. It can solve problems such as easy rotation of the fixing seat, difficult positioning of the fixing seat, and low accuracy of test results. To achieve the effect of improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

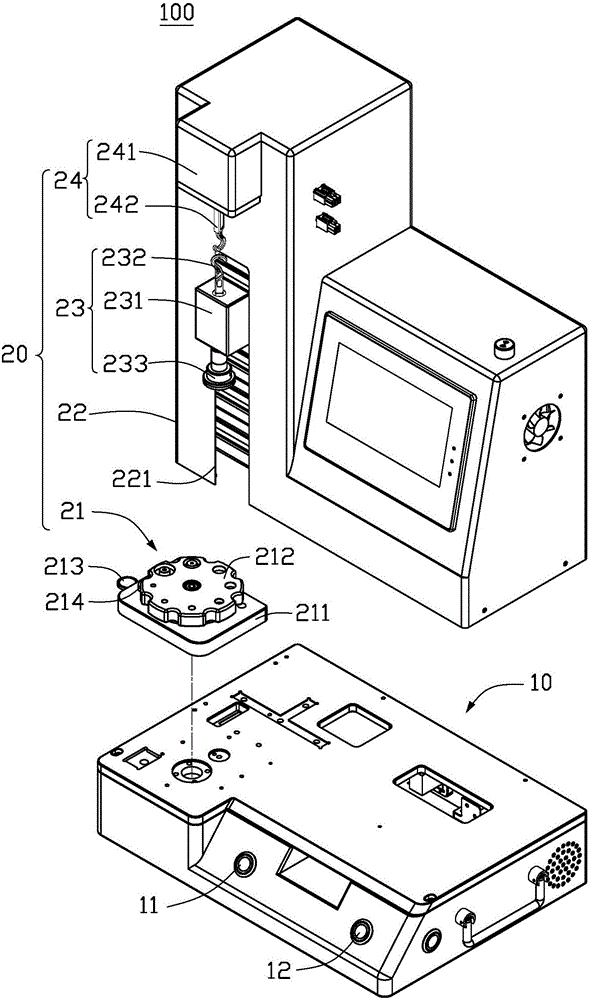

[0038] Please see figure 1 , a structural diagram of a preferred embodiment of the testing device for spring mechanical properties of the present invention, the testing device 100 for spring mechanical properties includes an electric control box 10 , a spring mounting base 20 , and a display 30 . The spring mount 20 and the display 30 are respectively disposed on the upper surface of the electric control box 10 .

[0039] This electric control box 10 is provided with reset button 11, test button 12, some USB interfaces 13 (referring to Figure 11 ), and power socket 14 (see Figure 11 ). Operate the reset button 11 to reset the spring to be tested (referring to the initial position of the spring to be tested before testing). The test button 12 is operated to start the test of the spring to be tested. The USB interface 13 is used to output the test results of the spring to be tested. The power socket 14 is used to provide power. In this embodiment, several USB interfaces ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com