Vamp flattening structure used in shoemaking process

A leveling and process technology, applied in the field of wrinkle removal tools, can solve the problems of increasing scrap rate, low leveling efficiency, worse leveling effect, etc., to avoid damage, improve efficiency, and avoid damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

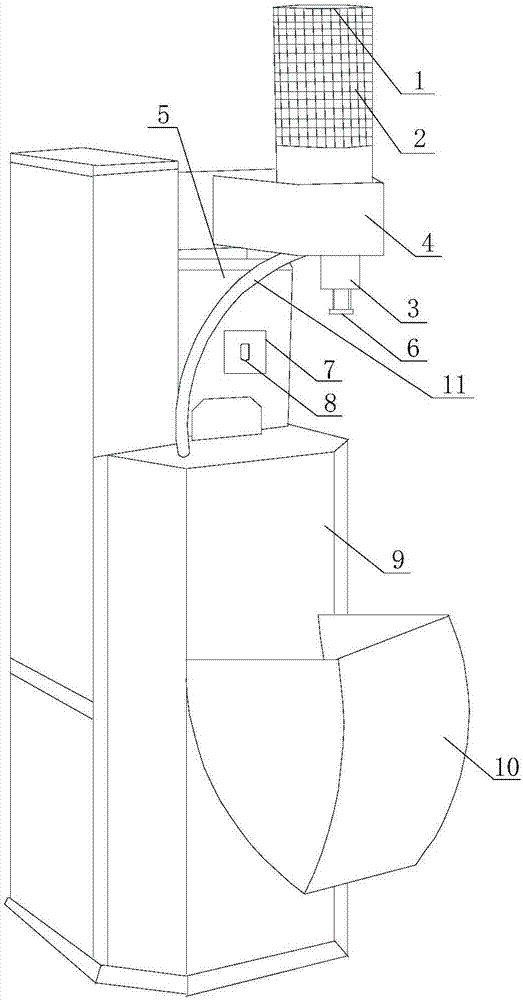

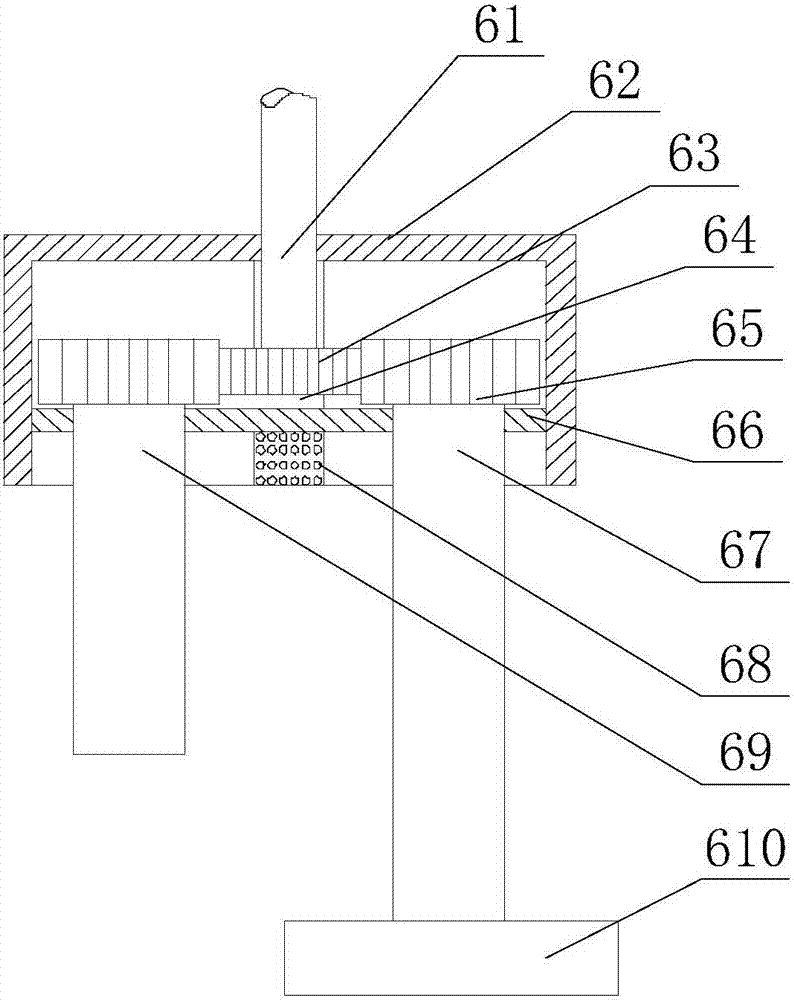

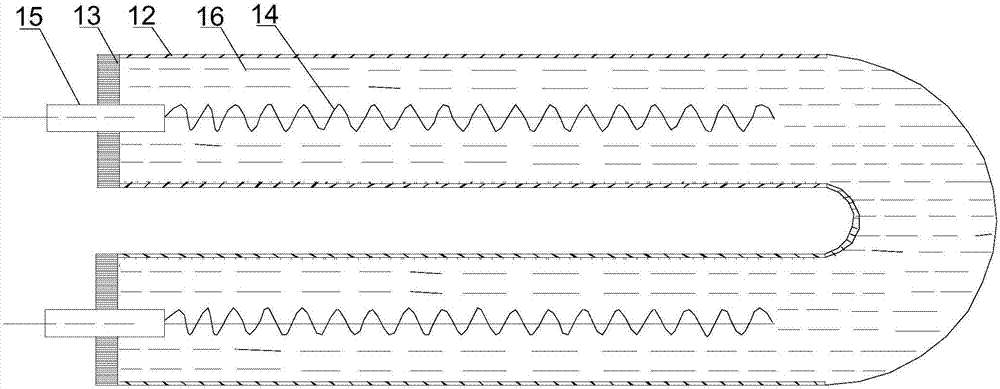

[0024] Such as Figure 1~3 As shown, this embodiment includes a body 9 and a mounting base 4 and a water tank 5 fixed on the side wall of the body 9. A fan, a motor, and an air inlet pipe 1 are provided at the upper end of the mounting base 4, and a flat surface is provided at the lower end of the mounting base 4. The assembly 6 and the water tank 5, the air inlet pipe 1 communicates with the air inlet end of the fan, and the output end of the motor movably penetrates the mounting seat 4 and then is linked with the leveling assembly 6. A duct 11 is provided on the side wall of the water tank 5, and the duct 11 An atomizer is provided at the end of the body; a collection frame 10 is also fixed on the body 9, and the frame of the collection frame 10 is directly below the flattening assembly 6; the flattening assembly 6 includes an opening fixed on the lower end of the mounting seat 4 The cylinder 62 facing the horizontal plane, one end of the rotating shaft 61 is connected with th...

Embodiment 2

[0028] Such as Figure 1~2 As shown, in this embodiment, the water tank 5 is also provided with a temperature sensor 7 and an alarm 8 connected to each other. The temperature sensor 7 is placed in the water tank 5 and the alarm 8 is placed outside the water tank 5. Due to the higher requirements of the wrinkle removal process, the processing time is more time-consuming, and the demand for the water in the water tank 5 is greater. When the water level in the water tank 5 is low, the temperature sensor 7 set in the water tank 5 transmits the water level information to the alarm 8, and the alarm 8 prompts the alarm in time, and the operator promptly replenishes the water, avoiding the lack of water. The empty consumption of the atomizer helps to maintain the equipment and improve the efficiency of the equipment.

[0029] Preferably, the extension section of the air outlet pipe 64 is placed between the first roller 67 and the second roller 69, so that the hot air and mist that overf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com