Stamping die guiding and positioning mechanism

A technology of guiding positioning and stamping dies, which is applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., and can solve the problem of low positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

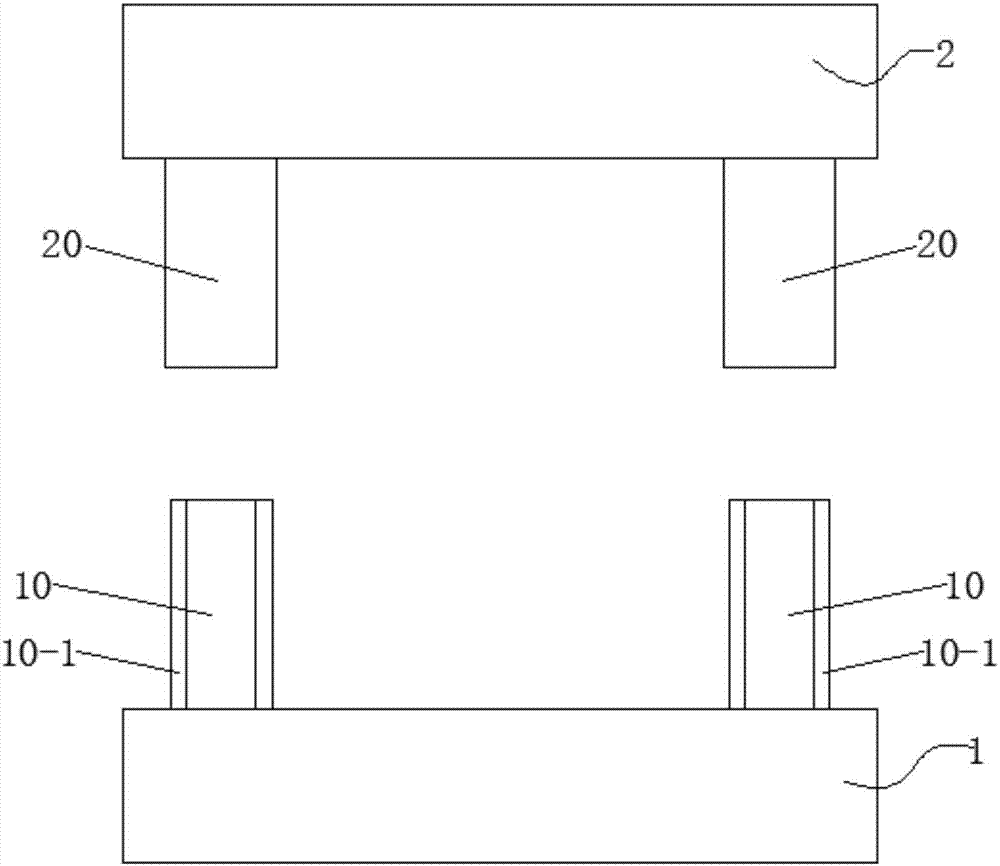

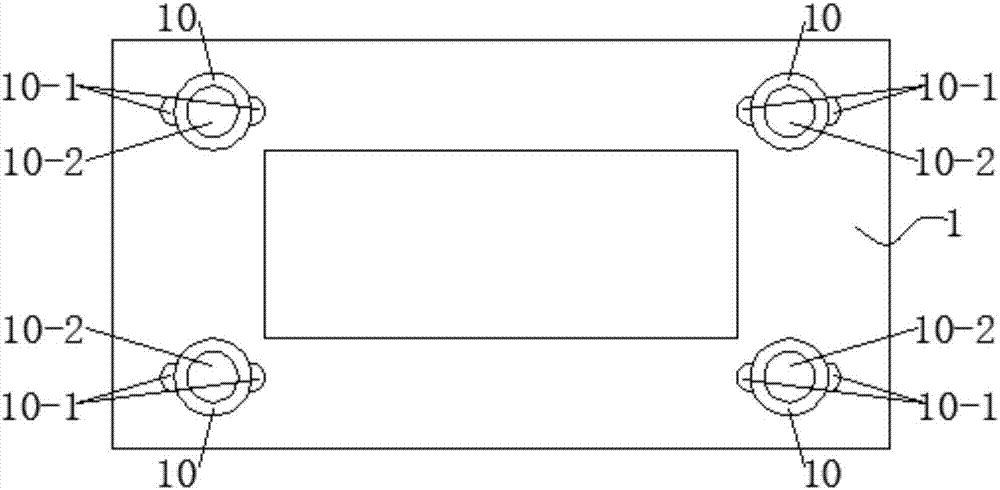

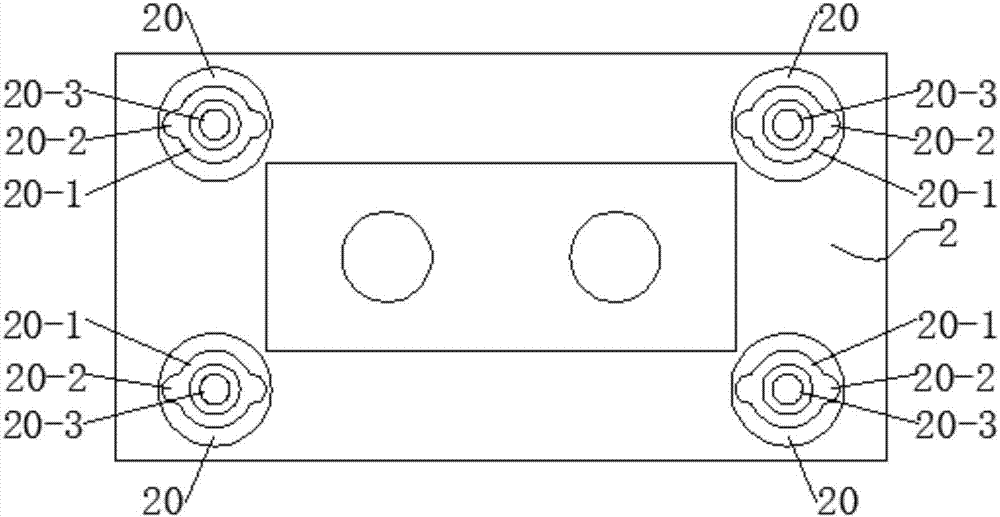

[0026] The stamping die guide positioning mechanism, when the upper mold base 2 and the lower mold base 1 are closed, the guide rod 20-3 on the upper mold base 2 is inserted into the positioning hole 10 in the positioning sleeve 10 on the lower mold base 1 from top to bottom In -2, the diameter of the guide rod 20-3 is the same as the diameter of the positioning hole 10-2, so that the positioning accuracy can be improved by the axis of the positioning sleeve 10 being coaxial with the axis of the guide rod 20-3.

Embodiment 2

[0028] During the clamping process of the upper mold base 2 and the lower mold base 1, the guide groove 20-2 on the inner wall of the guide sleeve 20 is inserted into the positioning bar 10-1 on the outer wall of the positioning sleeve 10 from top to bottom, and passes through a positioning hole 10-1. 2 axes and the axes of two positioning strips 10-1 are co-linear with the axes of a guide rod 20-3 and two guide grooves 20-2 respectively, limiting the lateral displacement of the upper mold frame 2 and the lower mold frame 1, improving In order to improve the precision of the guiding and positioning of the stamping die, avoid the lateral displacement between the upper mold frame 2 and the lower mold frame 1.

[0029] The front end of the guide rod 20-3 has a taper to realize the smoothness of mold clamping; one end of the guide rod 20-3 is provided with an external thread, and the guide rod 20-3 is connected with the upper mold frame 2 through the external thread to ensure The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com