Cinnabar relief painting forming device

A relief, cinnabar technology, applied in special decorative structures, decorative arts, etc., can solve the problems of human health damage, inhalation of cinnabar dust, etc., to reduce manual operations and avoid damage to human health.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

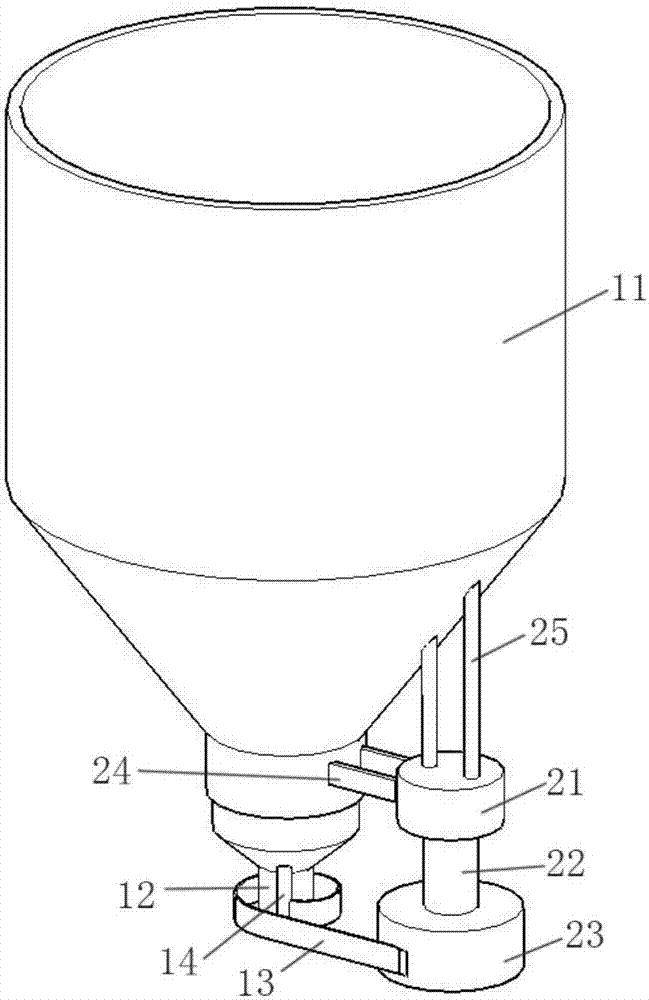

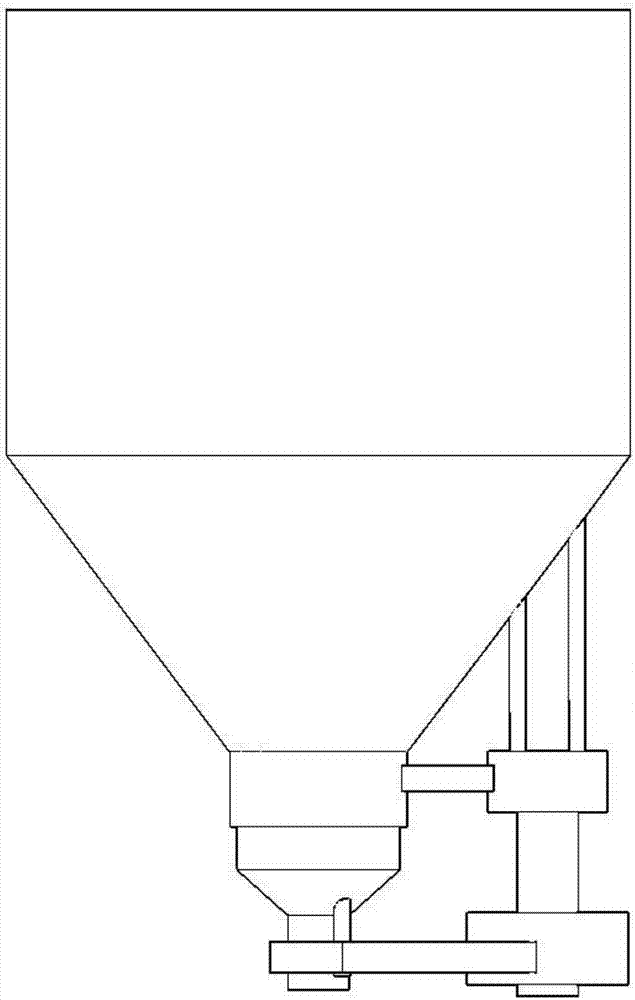

[0018] Such as figure 1 , figure 2 A kind of cinnabar relief painting forming device shown, comprises material bucket 11, discharge opening 12; Said material bucket 11 is the vertebra body bucket shape of upper big and lower bottom, and the bottom of material bucket 11 connects and fixes discharge opening 12, and discharge The mouth 12 is a soft rubber cone, and the outer ring of the lower part of the discharge port 12 is wound with an adjustment belt 13. The inner end of the adjustment belt 13 is on the discharge port 12, and the outer end of the adjustment belt 13 is driven by the adjustment motor 21 through the adjustment shaft 22. The motor 21 is fixed on the bottom side of the bucket 11 through a horizontal fixing rod 24 .

[0019] The horizontal fixing rods 24 are two horizontally juxtaposed.

[0020] The upper end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com