Method for building scaffold device in hyperboloid linear cabin

A kind of scaffolding and hyperboloid technology, which is applied in the field of erection of hyperboloid linear cabin scaffolding devices, can solve the problems of increased risk, long period, and prolonging the construction period of the dock, so as to improve safety, speed up construction and shorten the period of the dock Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

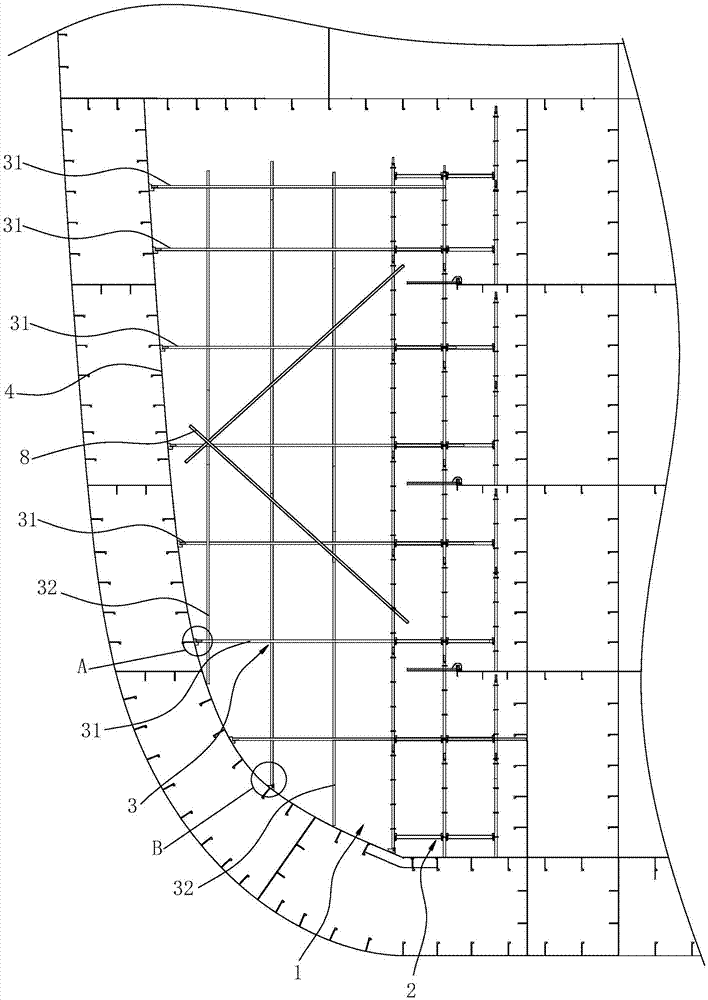

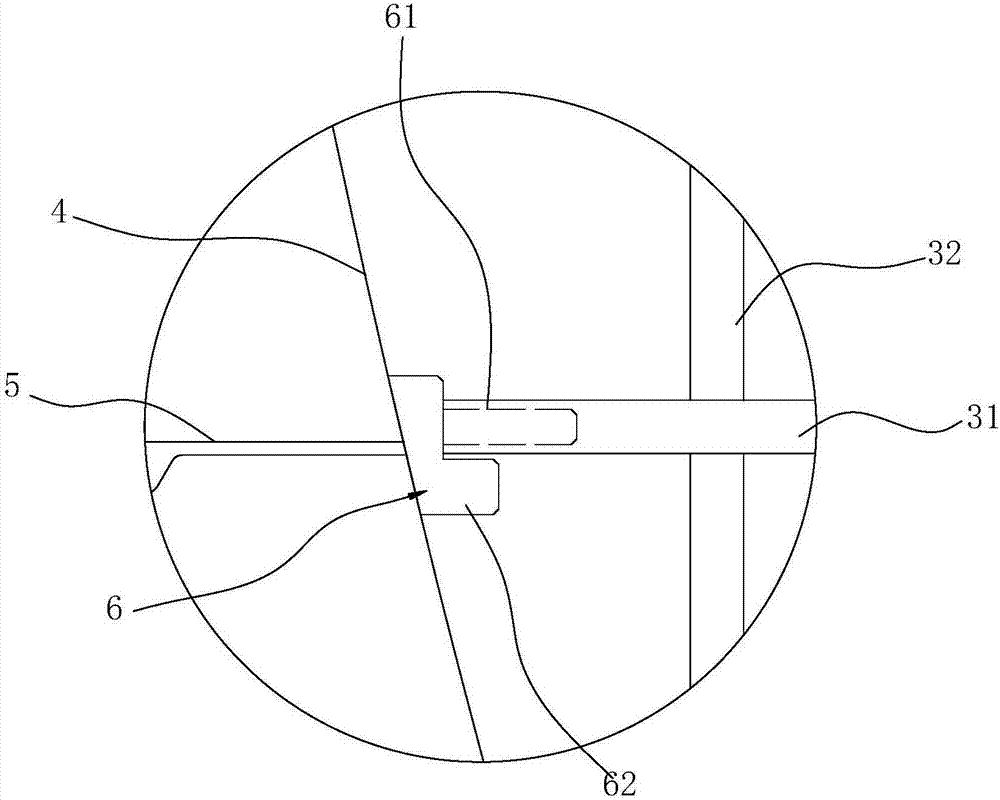

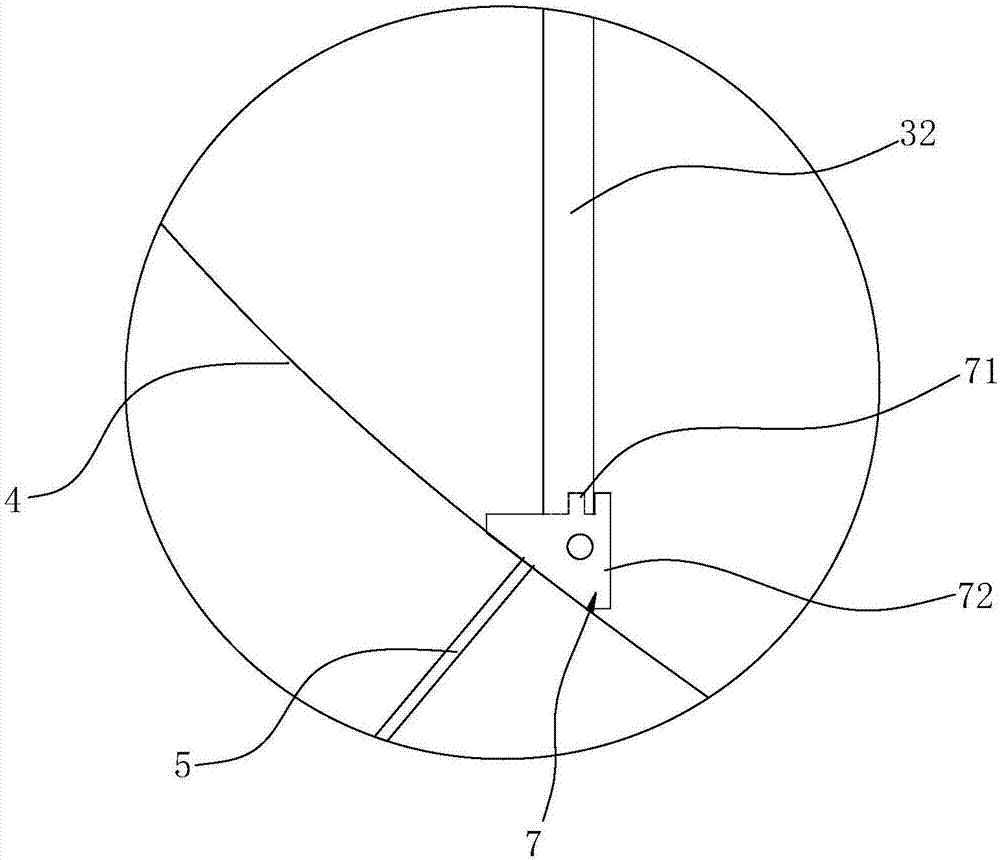

[0029] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0030] like Figure 1~3 As shown, in this embodiment, a method for erecting a hyperboloid linear cabin scaffolding device according to the present invention first installs the scaffolding code on the segment, and then closes each segment in the dock stage and then installs it in the cabin 1 Set up scaffolding inside.

[0031] The dock is an important resource in the shipyard. The installation of the scaffolding is completed before the dock stage, which reduces the time spent on the dock during the construction of the construction platform in cabin 1. When the sections are closed, they enter the docking stage, and scaffolding can be built according to the scaffolding codes installed on the sections, which greatly reduces the time taken to build the scaffolding, speeds up the advancement of cabin 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com