A shock-absorbing and isolating system for long-span bridges

A seismic isolation, large-span technology, applied in bridges, bridge construction, bridge parts, etc., can solve the problems that the seismic design of bridges is difficult to meet the design requirements, the plane size is large, and the installation space requirements are high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

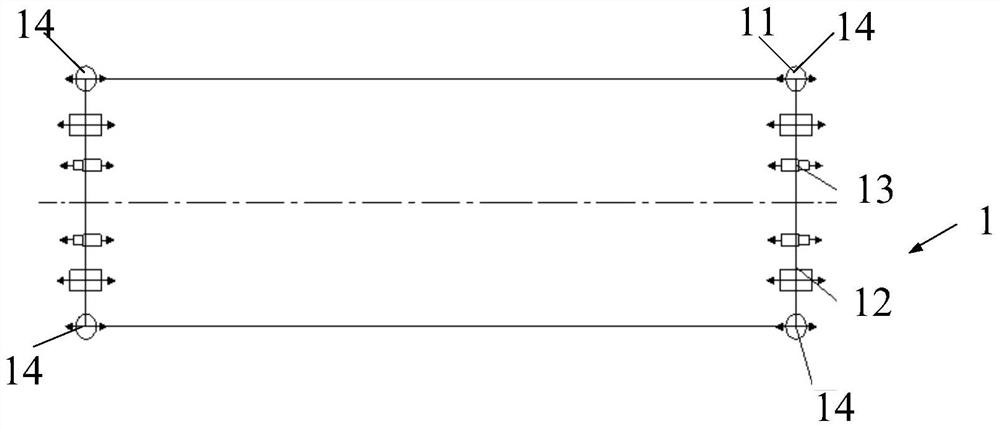

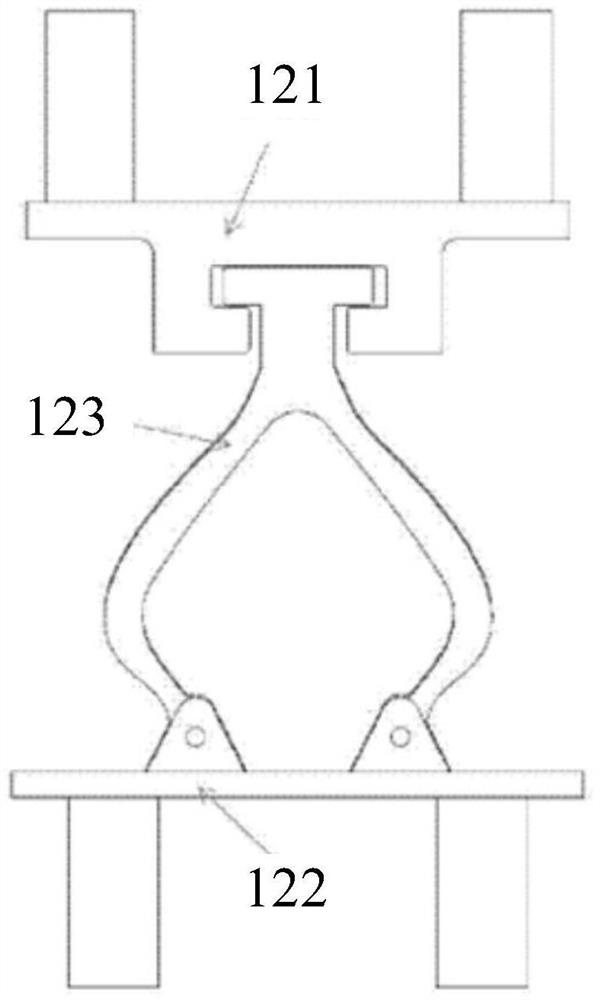

[0030] like figure 1 It shows the present embodiment of the large-span bridge shock absorption and isolation system of the present invention, and the long-span bridge is a bridge with a single-span span greater than 100m. In this embodiment, the large-span bridge shock-absorbing and isolation system includes two sets of main shock-absorbing assemblies 1, and the two sets of main shock-absorbing assemblies 1 are longitudinally and symmetrically arranged along the bridge deck. The damper 12 and the longitudinal damper 13 are equipped with a shear member 111 inside the spherical support 11. When the horizontal load of strong wind and earthquake is applied, the shear member 111 is cut off, and the transverse damper 12 and the longitudinal damper 13 begin to play a role in consumption. can work. like figure 1 , in this embodiment, the large-span bridge shock-absorbing and isolation system is a floating system, wherein the longitudinal spherical bearing 14 is a conventional longit...

Embodiment 2

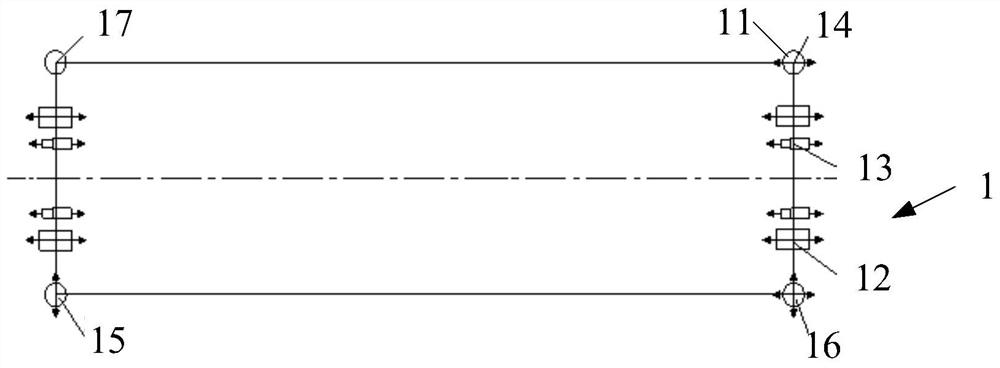

[0039] figure 2 It shows another embodiment of the long-span bridge vibration isolation system of the present invention. This embodiment is basically the same as the previous embodiment, except that the long-span bridge vibration isolation system of this embodiment is a semi-floating system. The spherical bearing 11 is a fixed spherical bearing 17, a longitudinal spherical bearing 14, a transverse spherical bearing 15, a two-way spherical bearing 16, a fixed spherical bearing 17, a longitudinal spherical bearing 14 and a transverse spherical bearing There are shear members 111 in the spherical support 15, and there is no shear member 111 in the two-way spherical support 16. When a large horizontal load is applied, the shear member 111 is cut off, and the transverse damper 12 and longitudinal damper 13 start play an energy-consuming role. Among them, the fixed spherical bearing 17 is a conventional fixed spherical bearing 17, which is used to fix the bridge structure on the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com