Large swing angle vector nozzle hybrid mechanism

A technology of mixed nozzles and mixed mechanisms, which is applied in the aviation field, can solve the problems of poor rectification and sealing, small rotation angle, difficult axisymmetric convergence and expansion adjustment, etc., and achieve flexible rotation, simple control, rectification and sealing good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

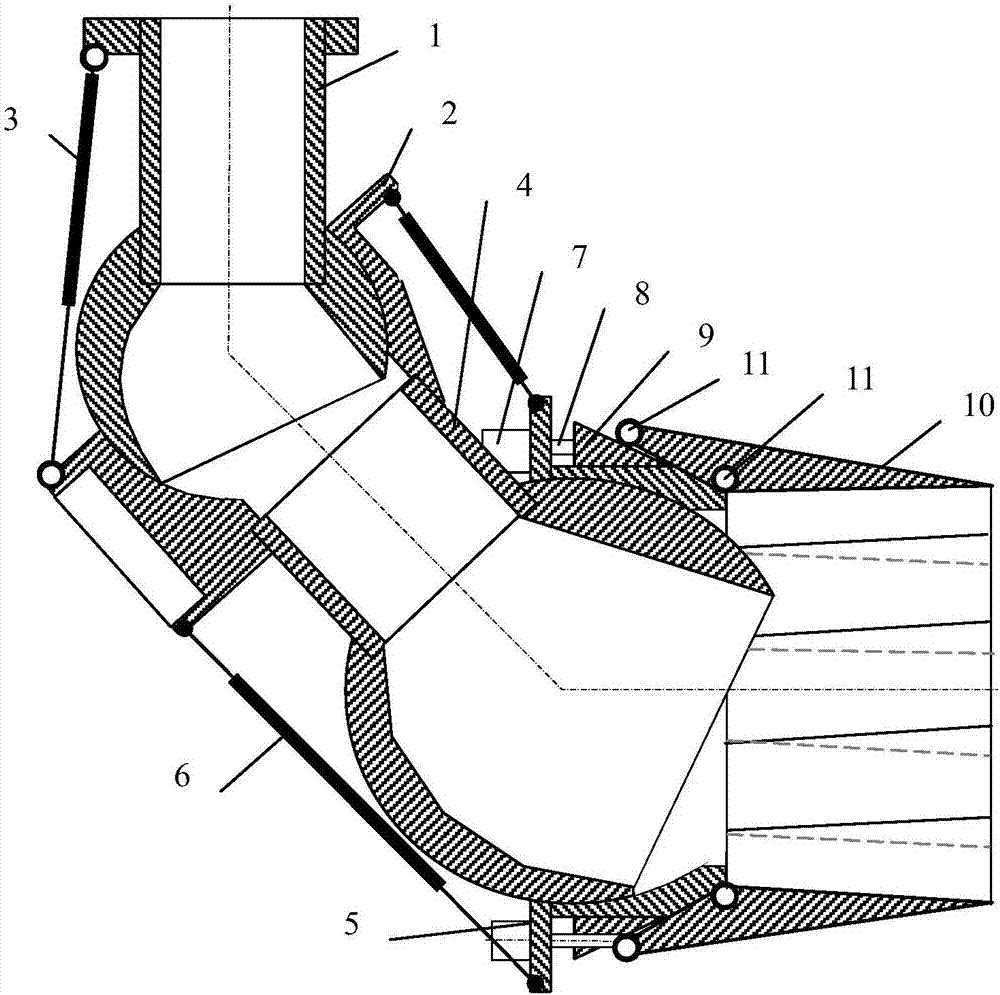

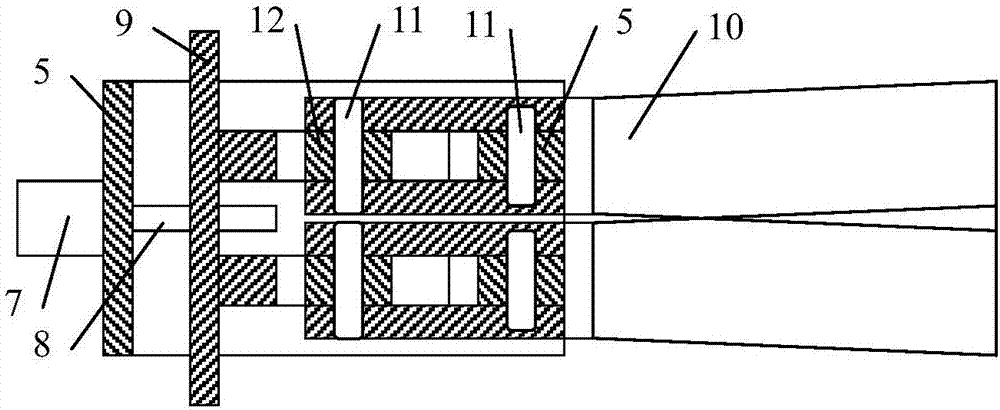

[0015] exist figure 1 In the schematic diagram of the large-swing angle vector nozzle hybrid mechanism shown, the small ball sleeve 1 is a cylinder with a cylindrical boss at the end and a convex spherical surface fixedly connected with the cylinder. The center of the cylindrical part is provided with an axial through hole. The convex spherical surface is provided with a coaxial arc-shaped through hole, the center of the small ball seat 2 is provided with a concave spherical surface hole, and its end is provided with a cylindrical boss, and the axial direction is provided with a coaxial cylindrical through hole. In the concave spherical surface hole at one end of the ball seat; the large ball sleeve 4 is a cylinder and a convex spherical surface fixedly connected with the cylinder, the center of the cylindrical part is provided with an axial through hole, and the convex spherical surface is provided with a coaxial arc-shaped through hole, and the large ball seat 5 The center i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com