Worm gear structure concurrently serving as limiting mechanism

A technology of limit mechanism and worm gear, which is applied in the field of uranium enrichment, can solve the problems of high machining precision and difficult manufacturing of end cover bosses, so as to save the use of precious metals, save processing man-hours, and facilitate assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

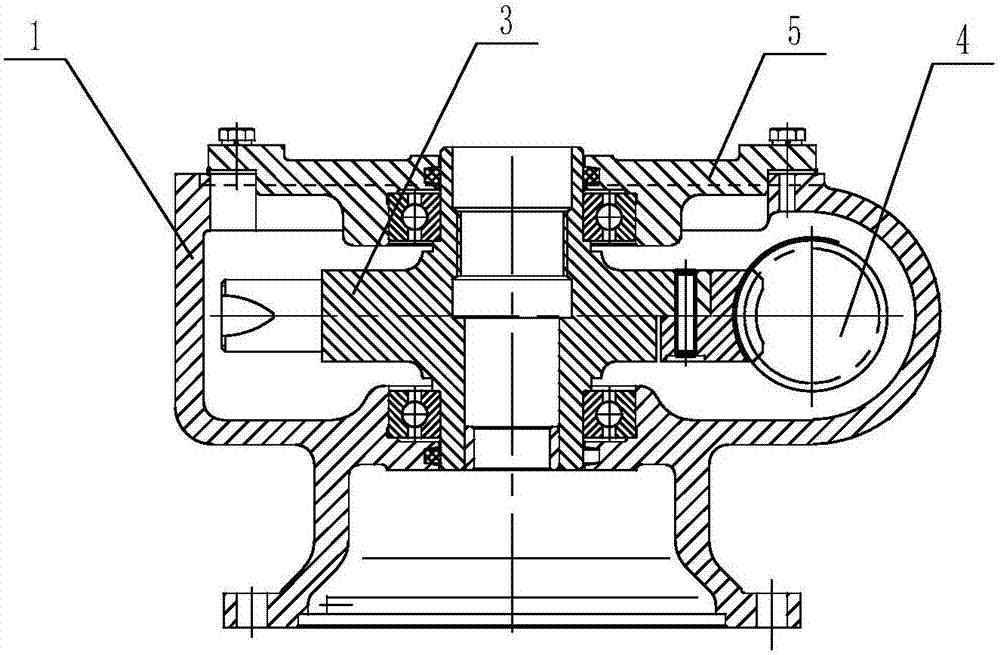

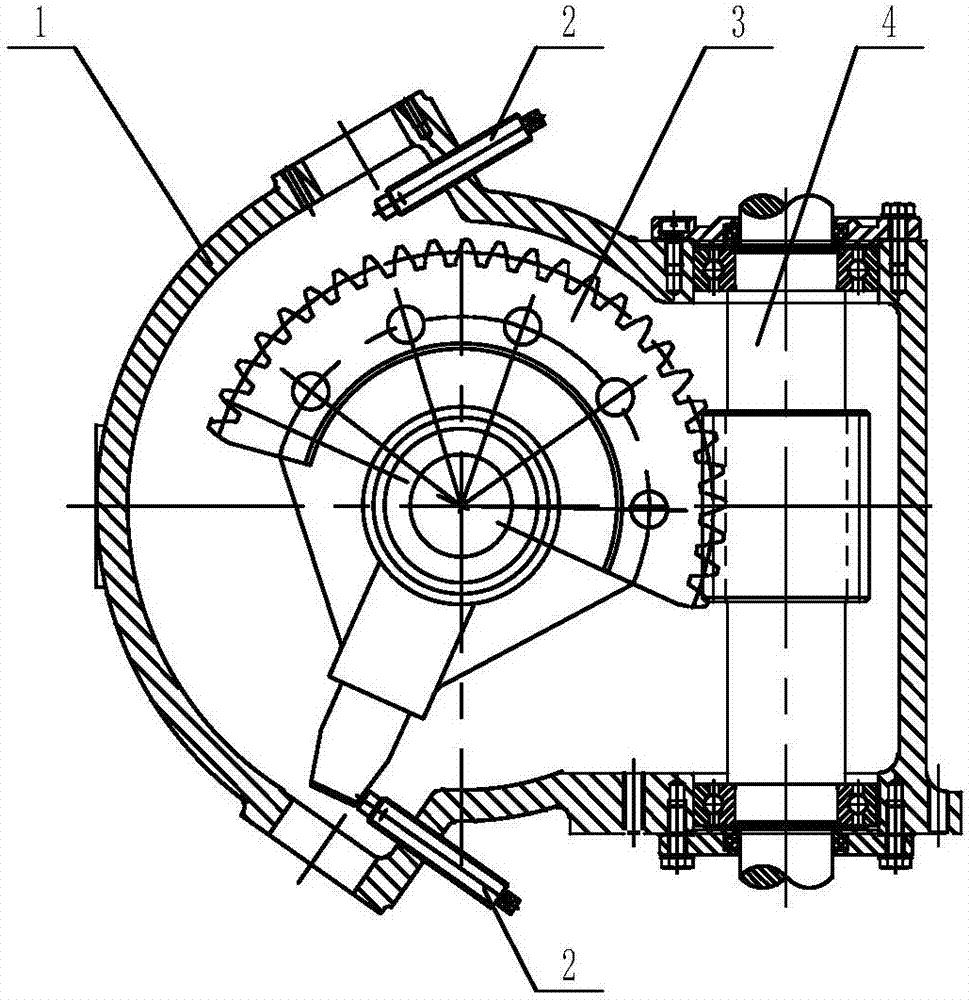

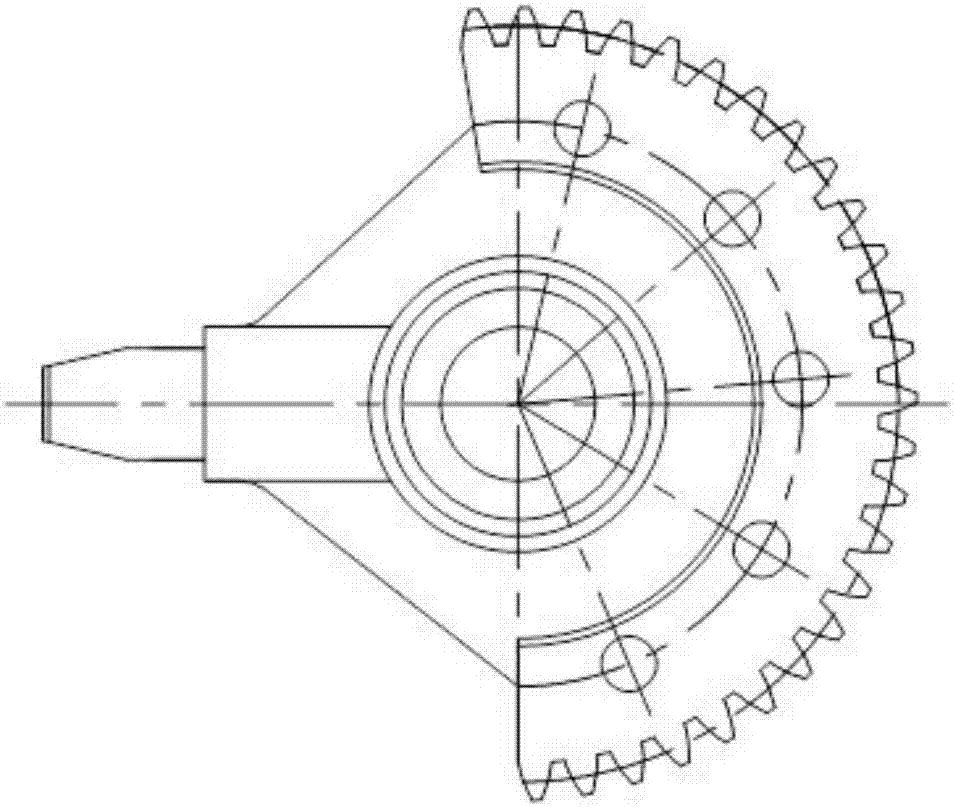

[0018] Such as figure 1 As shown in -3, the worm gear structure that doubles as a limit mechanism of the present invention includes a casing 1, an adjustment screw 2, a worm wheel 3, a worm screw 4, and an end cover 5;

[0019] The box body 1 is a steel casting. The right half of the structure is a hollow cylindrical structure, and the left half is a special-shaped hollow cylindrical structure. The space between the left half and the right half is staggered at 90°. The upper part of the left half is connected to the end cover 5 by bolts. , the lower part connects other components. The worm wheel 3 is arranged on the left half of the box body 1, and the worm 4 is arranged on the right half, and at the same time, it can be ensured that the worm wheel 3 and the worm 4 are in an meshing state. The special-shaped structure of the left half of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com