Switching device for electric and manual actuating mechanisms of nuclear drum vacuum valve

An electric actuator, the technology of the actuator, applied in the direction of the valve operation/release device, valve device, engine components, etc., can solve the problems of complex structure of the switching device, high hazard of materials, high price, etc., to achieve enhanced operational flexibility, The effect of meeting operational needs and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

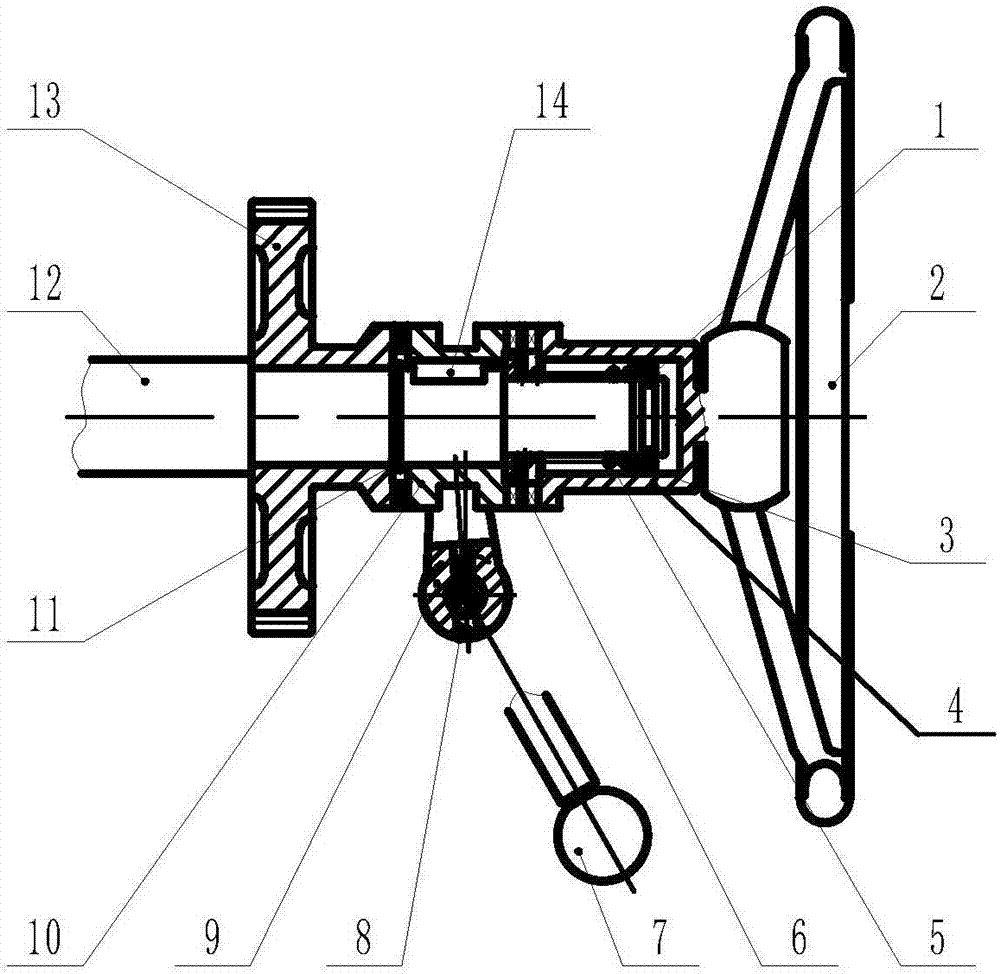

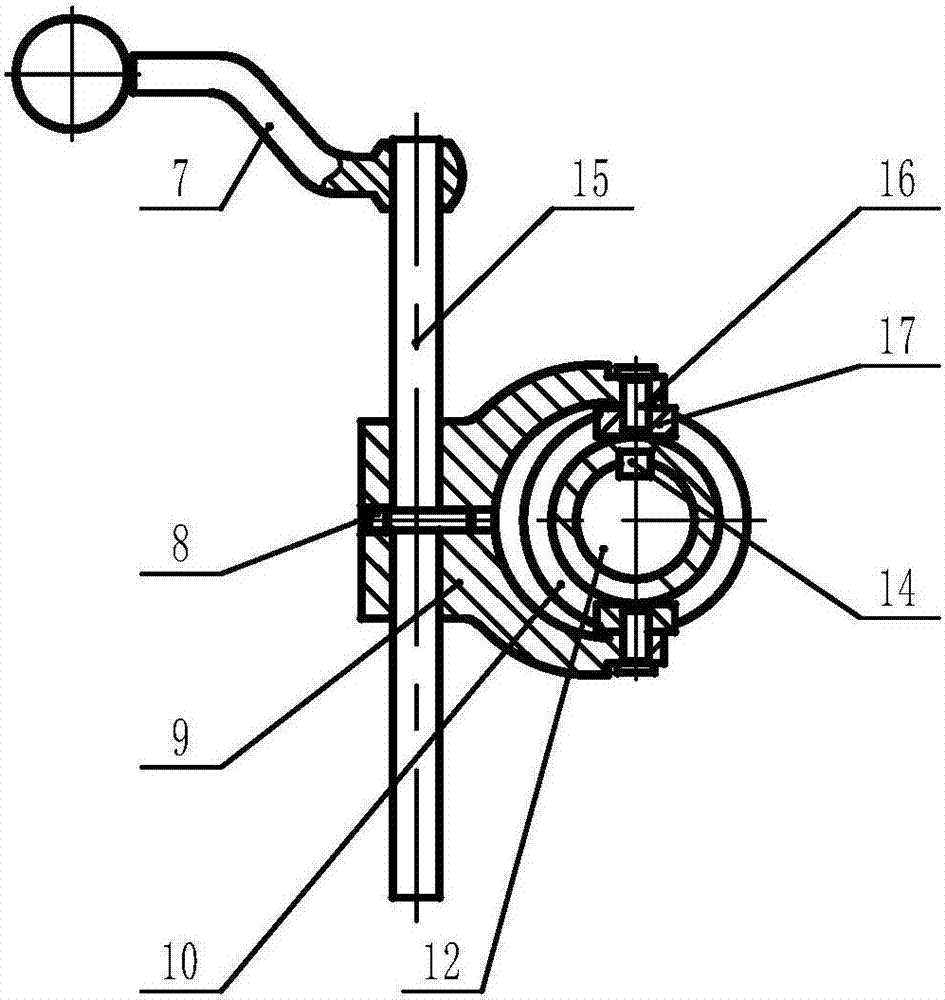

[0016] Such as figure 1 As shown in -2, the switching device of the nuclear drum vacuum valve electric manual actuator of the present invention includes a half washer 1, a hand wheel 2, a spring seat 3, a rear coupling sleeve 4, a spring 5, and a stopper for the first shaft. Ring 6, handle 7, set screw 8, shift fork 9, front coupling sleeve 10, retaining ring for the second shaft 11, worm shaft 12, large gear 13, key 14, shaft 15, pin shaft 16, slider 17 ;

[0017] Large gear 13, retaining ring 11 for the second shaft, front-end coupling sleeve 10, retaining ring 6 for the first shaft, spring 5, spring seat 3, two half washers 1, rear coupling sleeve 4, hand wheel 2 and The worm shafts 12 are coaxial respectively, and are loaded into the worm shafts 12 sequentially from the back to the front. The diameter of the worm shaft 12 decreases in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com