Harness connector and cable connection method

A wire harness connector and cable technology, which is applied in the direction of connection, connection device components, and contact assembly/disassembly, etc., can solve problems such as hidden safety hazards, large external damage to cables, and large volume, and achieve reliable connection. , low cost and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in further detail below in conjunction with the accompanying drawings.

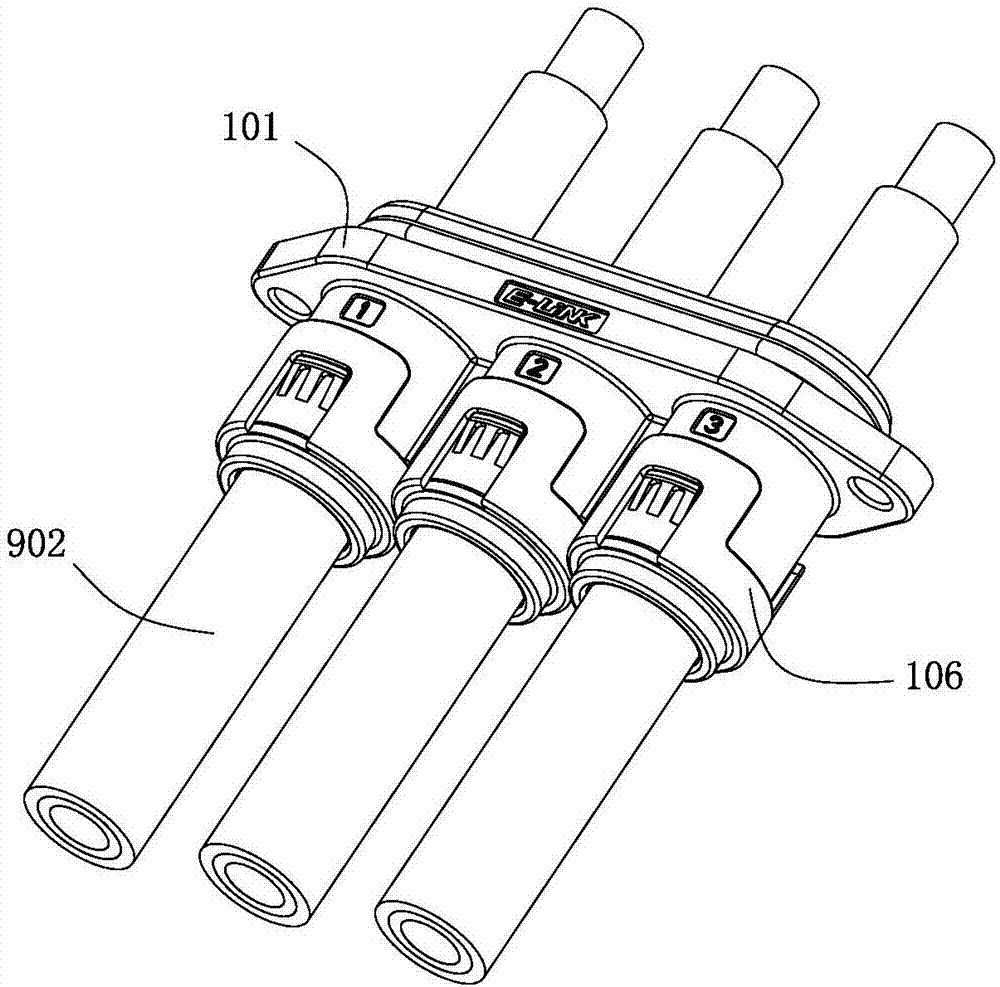

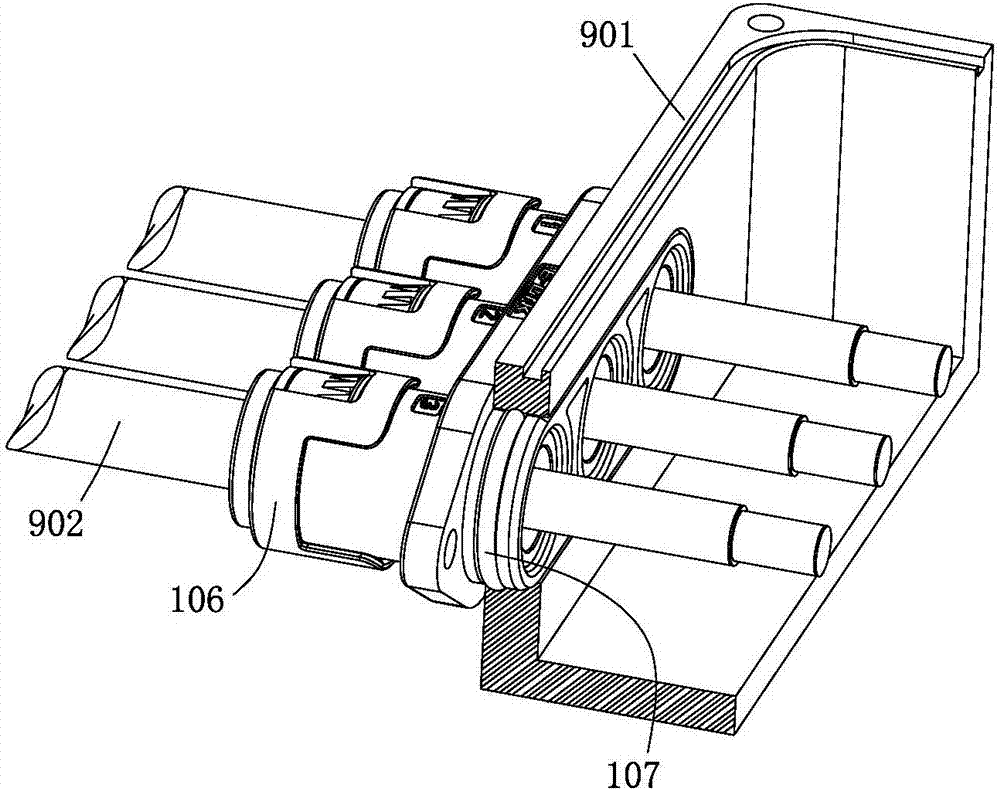

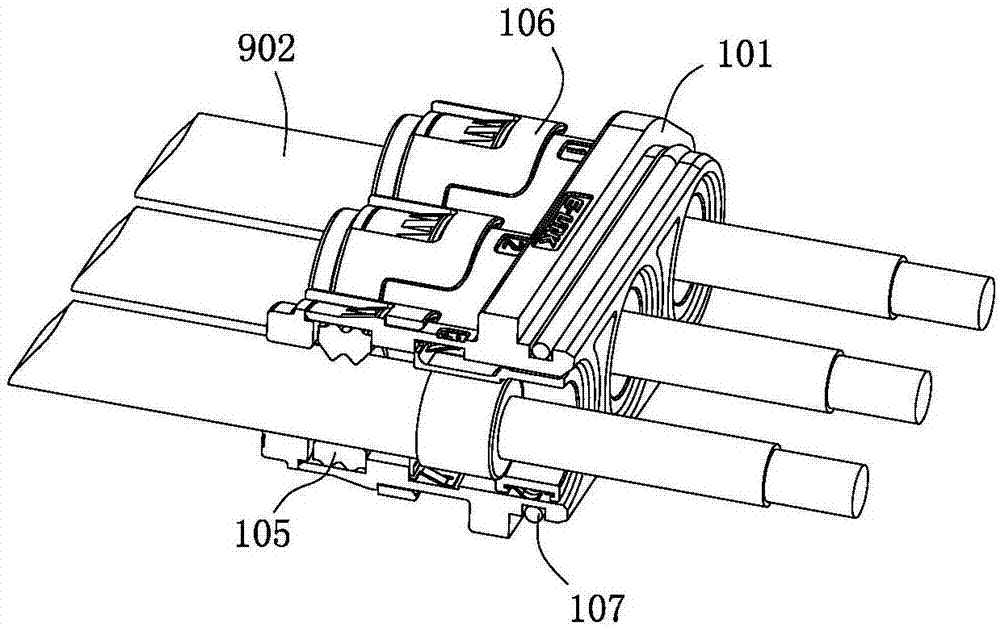

[0042] refer to Figure 1 to Figure 5 , the first embodiment of the present invention is a wire harness connector, including a metal shell 101, the metal shell has an outer edge and a plurality of inner holes, each inner hole is divided into a front section and a rear section by a flange; There is a shielding ring 102, a shielding band 103 sleeved on the front of the shielding ring, and a fixing claw 104 sleeved on the rear of the shielding ring; The part is also provided with a rear cover 106.

[0043] The cable sealing body 105 is made of elastic material and has a ring shape, and ring-shaped ribs are provided on the outer surface and the inner surface. There are at least two annular ridges. On the outside of the metal shell 101 , an annular groove is provided in front of the outer edge, and an outer circular sealing ring 107 is arranged in the annular g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com