Motor assembling system

An assembly system and motor technology, applied in the direction of assembly machines, electromechanical devices, electric components, etc., can solve the problems of high defective rate of finished products, low assembly efficiency, relying on manual operations, etc., achieve a high degree of automation, reduce manual participation, provide Assembly efficiency and the effect of assembly quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

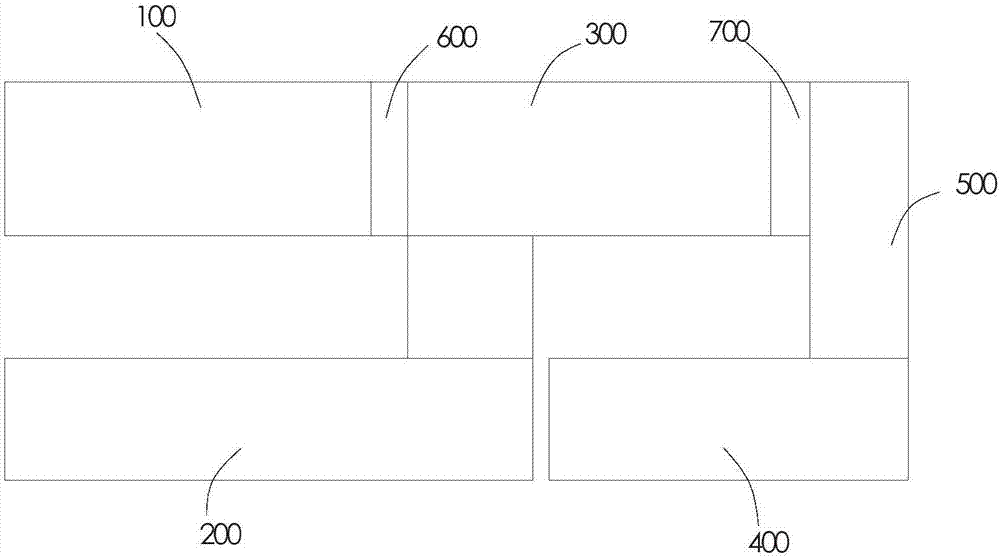

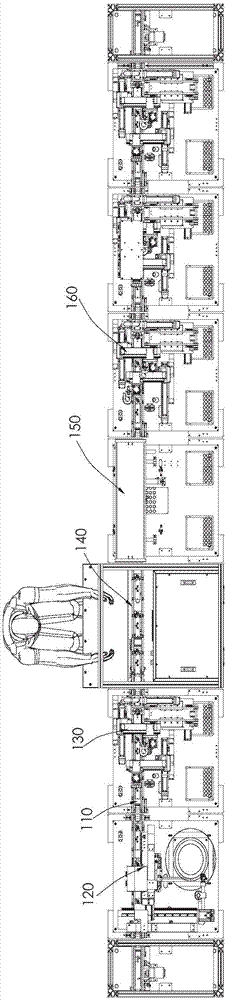

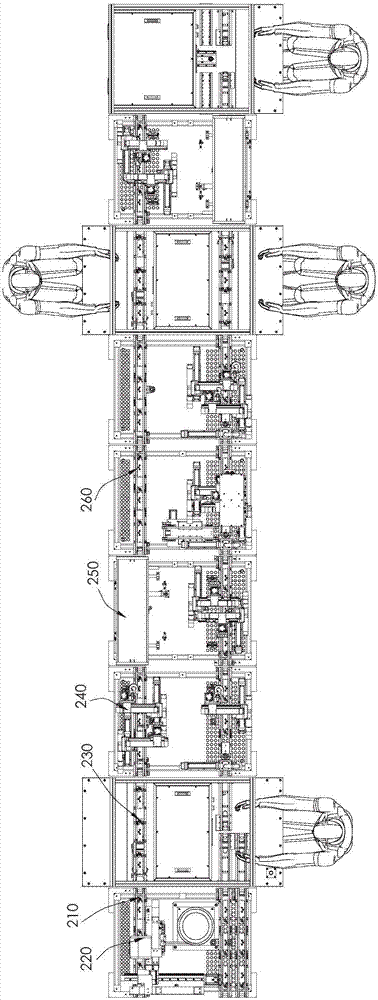

[0053] Such as Figure 1-4 The motor assembly system shown includes a coil and lower reed assembly section 100 , a motor base and a terminal assembly section 200 , a first assembly section 300 , a motor housing, an upper reed sheet and a magnet assembly section 400 , and a second assembly section 500 , the coil and the lower reed assembly section 100 are used to assemble the coil and the lower reed to form a first semi-finished product. The motor base and the terminal assembly section 200 are used to assemble the terminals to the motor base and form the second semi-finished product. The first assembly section 300, the starting end of the first assembly section 300 is connected to the end of the coil and the lower reed assembly section 100 and the end of the motor base and the terminal assembly section 200 respectively, and is used to assemble the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com