Automatic robot

A robot and connection technology, applied in the field of robotics, can solve problems such as low efficiency, slow speed, time-consuming and laborious, and achieve the effect of improving work efficiency, reducing maintenance costs, and reducing procurement costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

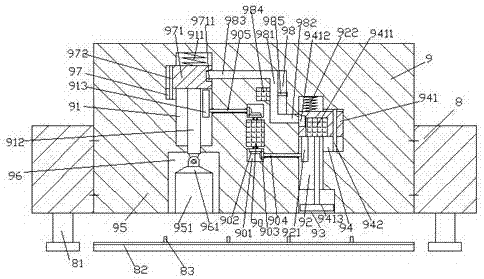

[0013] like figure 1 , figure 2 As shown, an automatic robot of the present invention includes a base body 8 and a main body 9 fixedly installed in the base body 8, a hammer leveling device and a vamp polishing device are arranged in the main body 9, and the hammer leveling device includes a set In the first sinker 95 in the bottom surface of the left side of the main body 9, a hammer flat block 951 is arranged in the first sinker 95, and a second sinker 96 is arranged in the inner top wall of the first sinker 95, The second sinker 96 is provided with a hinge 961 whose bottom is fixedly connected to the top of the hammer block 951, and the main body 9 above the second sinker 96 is provided with a first slide chamber 91, so A first sliding groove 97 is provided in the inner wall on the left side of the first sliding chamber 91, and a first sliding block 971 extended to the right is connected to the first sliding groove 97, and the first sliding block 971 is right The side ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com