Automatic needle insertion equipment

A pin insertion device and automatic technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of high repetition rate, easy hand damage, easy brain fatigue, etc., and achieve good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

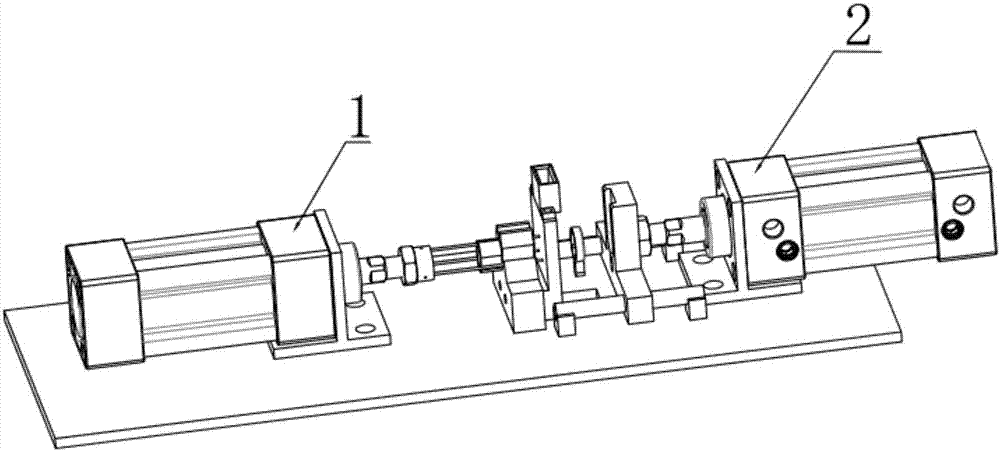

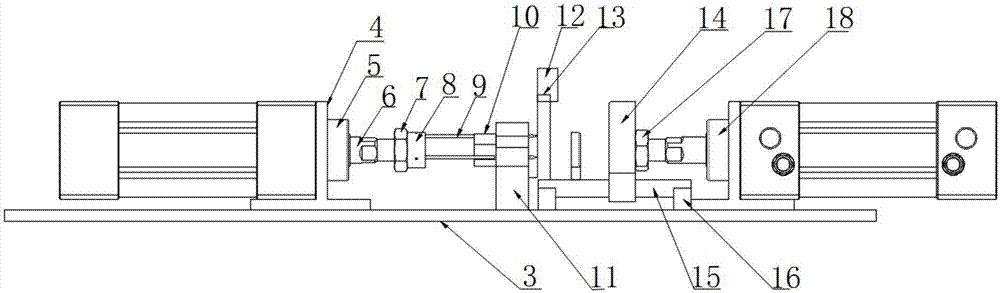

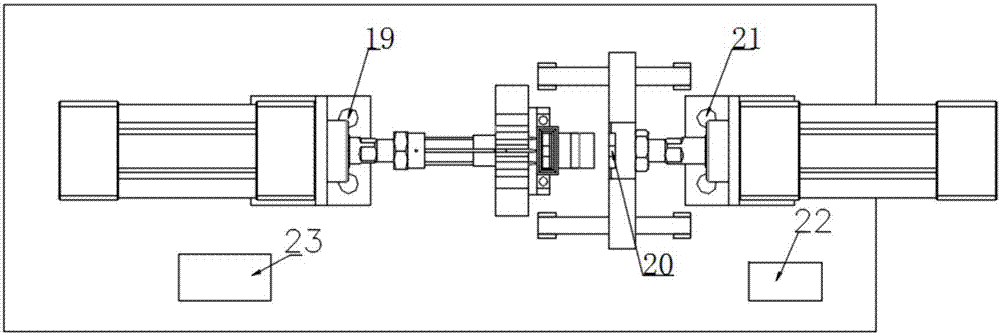

[0020] Such as figure 1 , 2 , 3, an automatic pin insertion device, including a pin insertion device 1, a discharge device 2, a base 3, a control system module 22, and a distribution box 23. The pin insertion device 1 includes: a fixed plate 4, a pin cylinder 5, a telescopic shaft 6, a clamping nut 7, a ferrule 8, a thimble rod 9, a push rod 10, a bracket 11, and a pin cylinder fixing plate hole 19; The fixed plate 4 is a 10mm thick T-shaped steel plate, which is integrally cut from structural steel; the pin cylinder 5 is fixed on the fixed plate 4, and the tail of the pin cylinder is in contact with the base 3; The telescopic shaft 6 is fixed on the pin cylinder 5; the clamping nut 7 is in contact with the side of the telescopic shaft 6, and the clamping nut 7 tightly withstands the ferrule 8; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com