Surface milling clamp for double workpieces

A double workpiece, milling surface technology, applied in the direction of manufacturing tools, metal processing mechanical parts, clamping and other directions, can solve the problems of time-consuming and laborious, accumulative error of clamping accuracy, etc., to reduce production costs, quickly switch processing, avoid installation. The effect of clipping cumulative errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

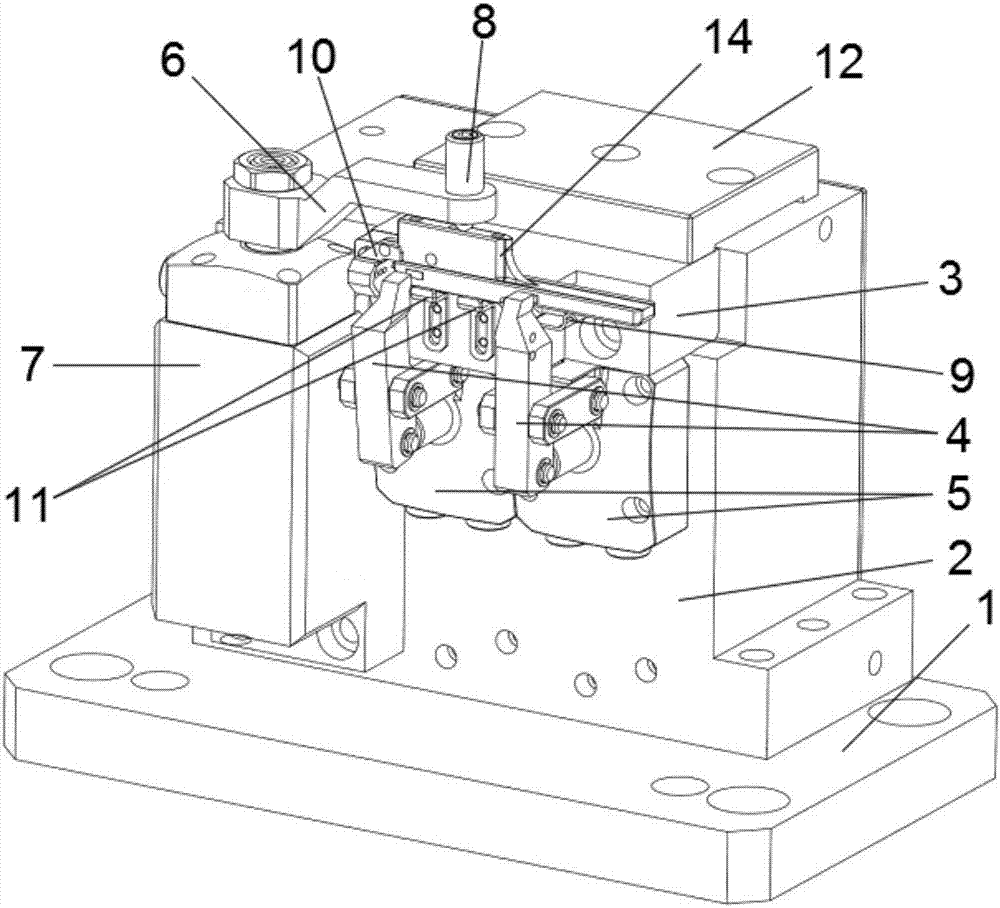

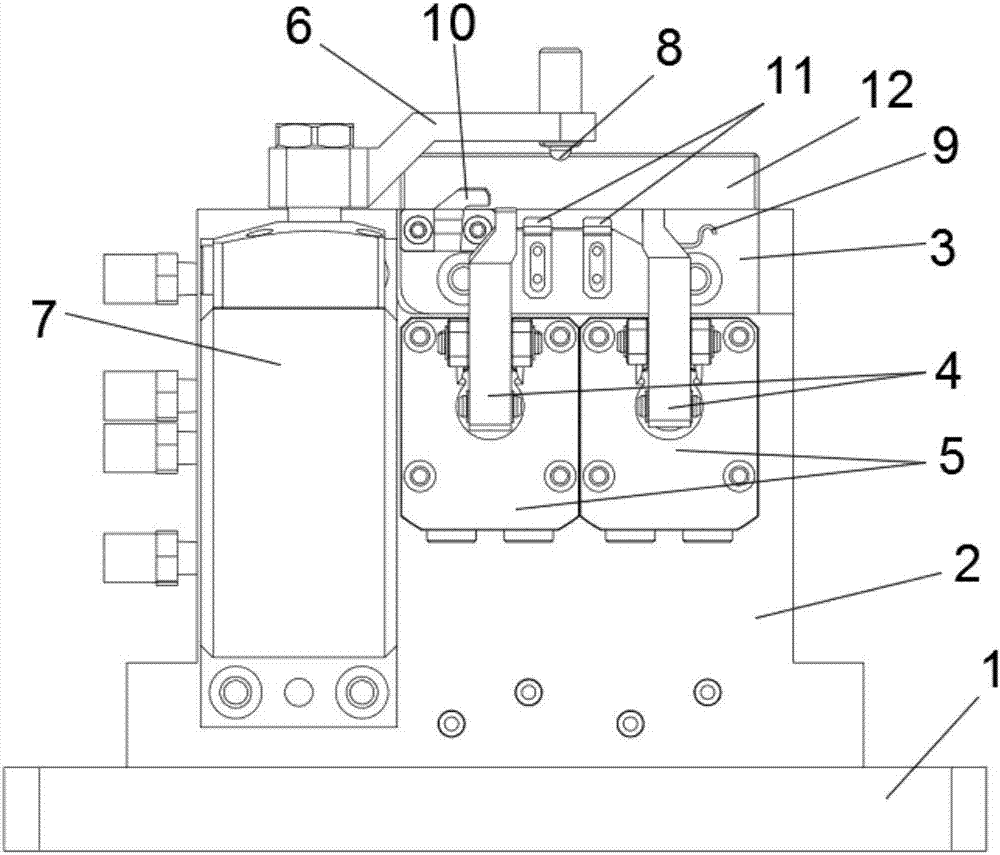

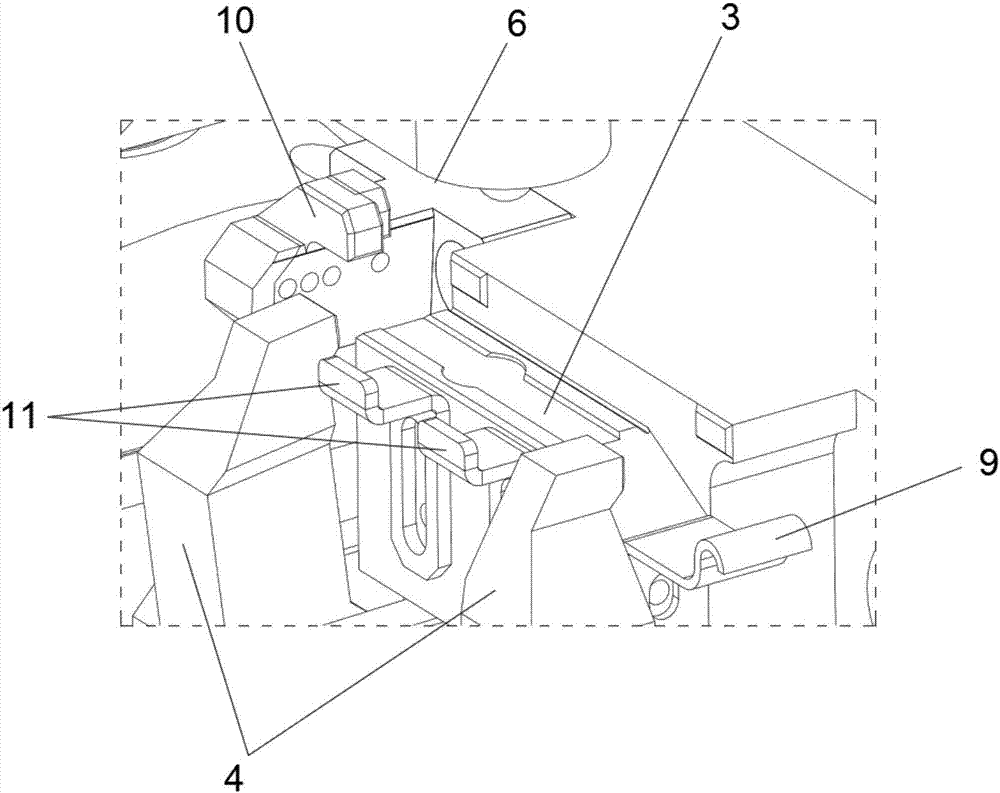

[0019] Such as Figure 1 to Figure 6 As shown, the present embodiment provides a double workpiece milling fixture, which includes a base plate 1; a mounting plate 2 is fixed on the base plate 1; a replaceable support seat is provided on the top of the mounting plate 2; A pressure block 12 is also arranged at the rear of the top surface of the replaceable support seat; the front of the installation plate 2 is located under the replaceable support seat and is provided with a main pressure mechanism 4; the main pressure mechanism 4 is driven by the main pressure cylinder 5 ; The top of the replaceable support seat is also provided with a pre-pressing plate 6; the right end of the pre-pressing plate 6 is provided with an elastic briquetting block 8, and the left end is connected with a pre-pressing cylinder 7; the pre-pressing plate 6 is driven by the pre-pressing cylinder 7 Rotation and lifting action; the replaceable support base includes a fixed end and a loading end; the fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com