A Closed-loop Vector Redundancy Control Method for Inverter in High-speed Operation

A technology of redundant control and frequency converter, applied in vector control system, control system, control generator, etc., can solve the problems of insufficiency, long redundant switching delay time, etc., to achieve short switching process, saving hardware cost, guaranteeing The effect of continuous and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with specific examples and accompanying drawings.

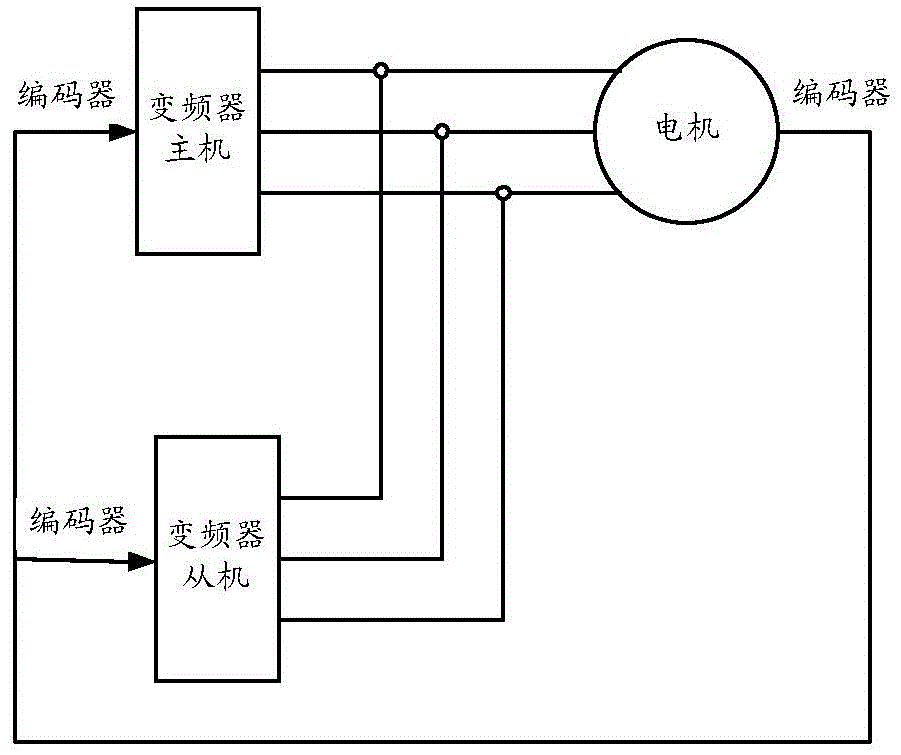

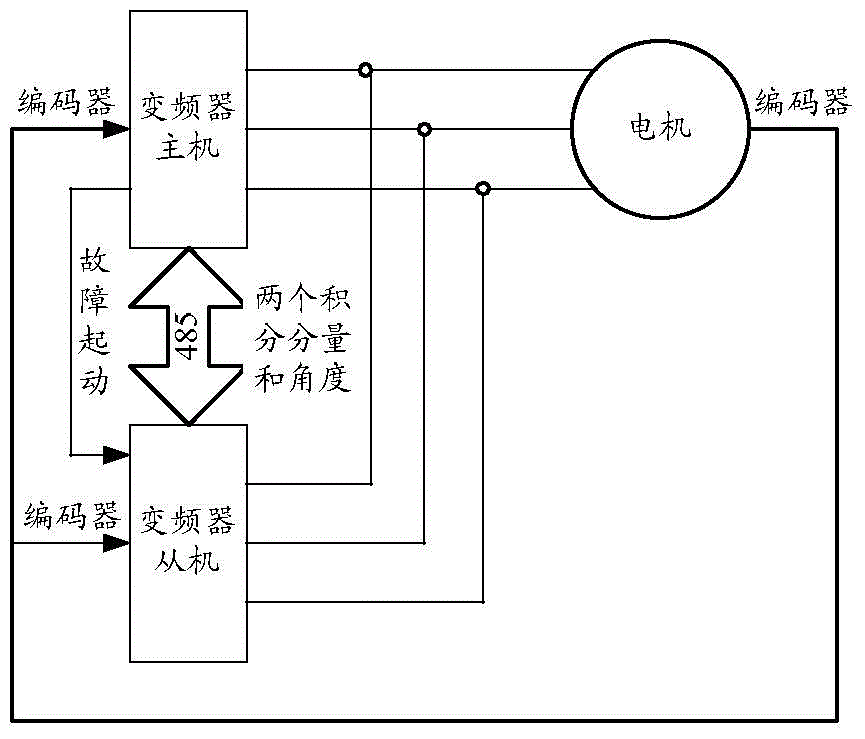

[0023] image 3 It is a schematic diagram of frequency converter closed-loop vector redundancy switching according to an embodiment of the present invention, which includes the following steps:

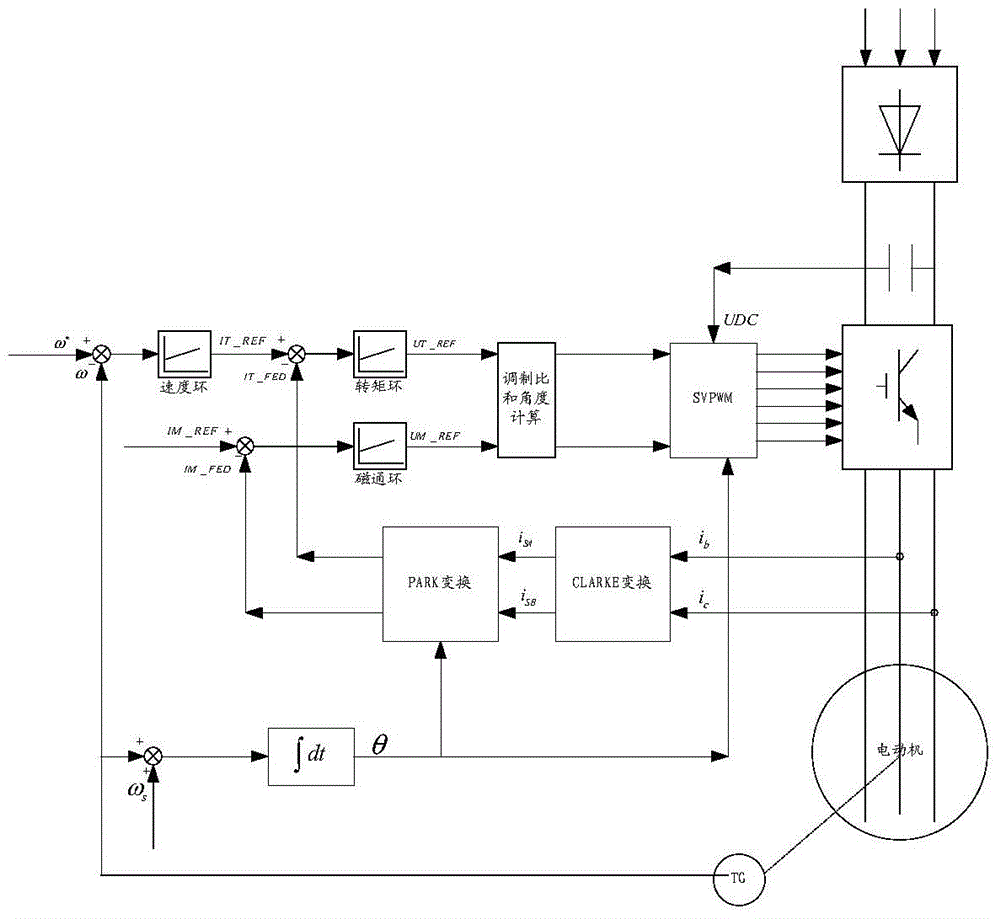

[0024] 1) The frequency converter master (in this embodiment via the 485 bus) periodically sends the integral component of the given value of the excitation voltage, the integral component of the given value of the torque voltage to the slave machine of the frequency converter, and the clip between the synthesized voltage vector and the reference axis A-axis Angle three physical quantities;

[0025] 2) When the inverter host fails, the inverter host (in this embodiment through the I / O port) sends a digital signal to the inverter slave. At this time:

[0026] The slave machine of the inverter takes the integral component of the excitation voltage given value...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com