Method for Rapid Establishment of Ethylene Polymerization/Copolymerization in Gas Phase Fluidized Bed Reactor

A gas-phase fluidized bed and ethylene polymerization technology, which is applied in the field of conventional chromium-based catalysts to catalyze ethylene polymerization/copolymerization to prepare corresponding polymers, can solve the problems of re-stopping and changing beds, affecting product quality, and difficulty in establishing reactions. The effect of short switching time, low price, and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

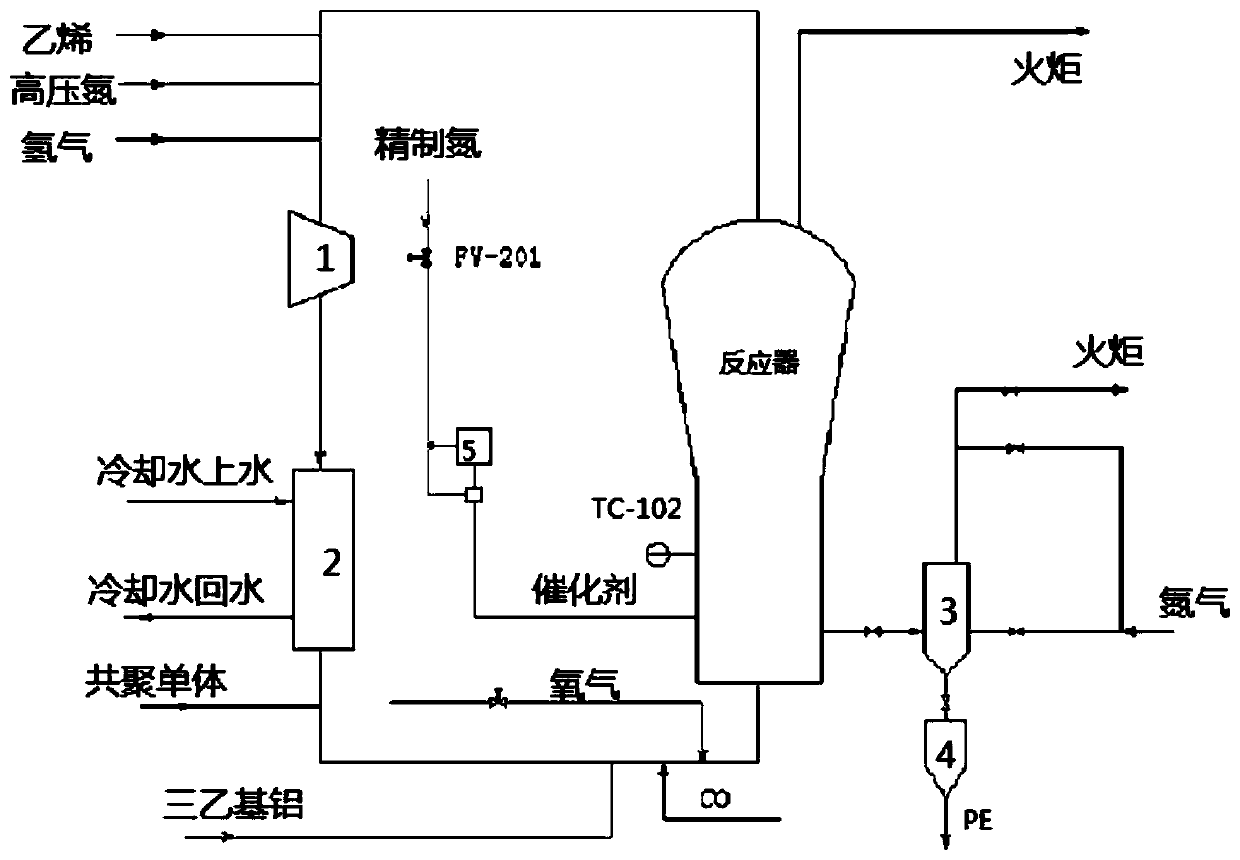

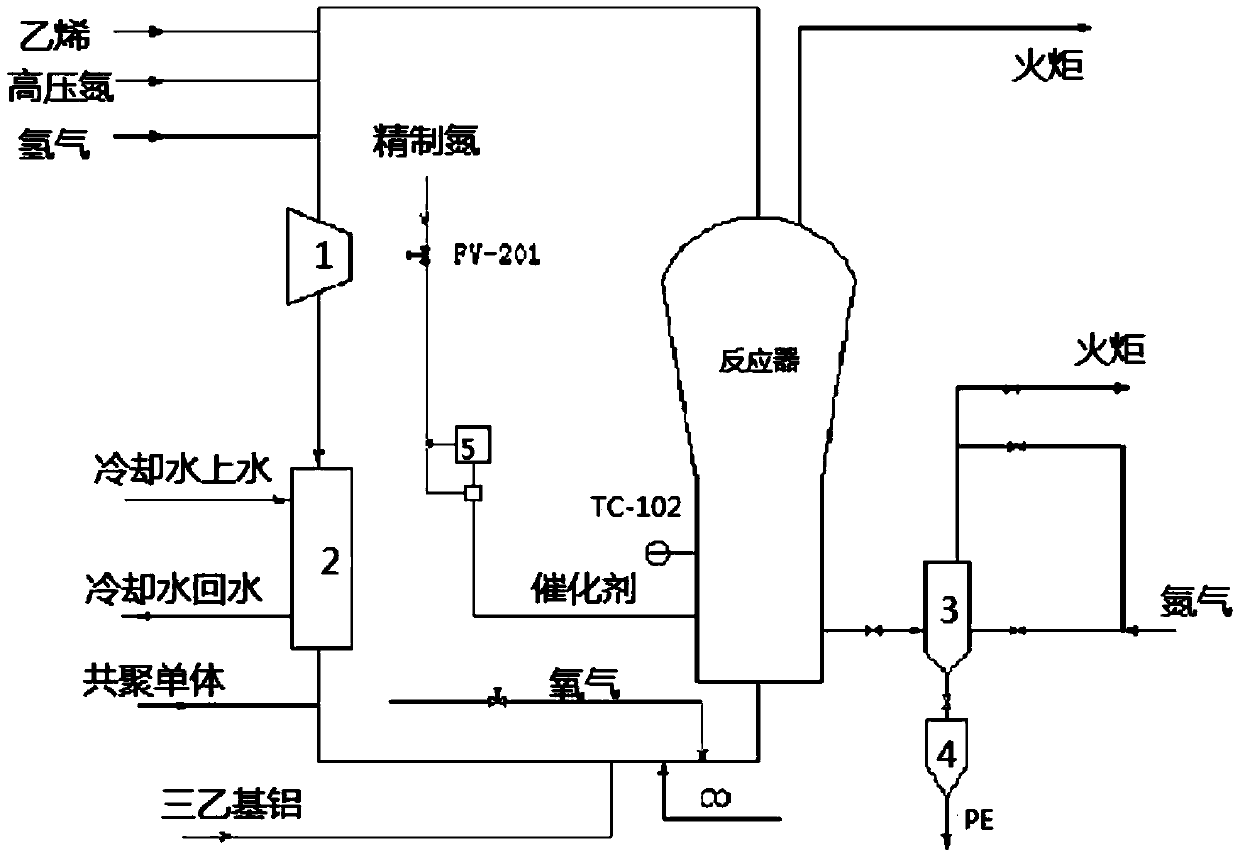

Image

Examples

Embodiment 1

[0047] A method for quickly establishing ethylene polymerization / copolymerization in a 50kg / hr gas-phase fluidized-bed reactor, comprising the following steps:

[0048] After filling 100kg of suitable seed bed into the reactor, after introducing nitrogen to replace the trace amount of water and oxygen in the reaction system, switch to ethylene, hydrogen, comonomer and other circulating gases to adjust the composition, and then add 0.01kg of organic The chromium-based S-2 type catalyst initiates the establishment of the polymerization reaction, and then switches to a conventional chromium-based catalyst, and at the same time stops adding the organic chromium-based S-2 type catalyst, and uses a conventional chromium-based catalyst to catalyze ethylene polymerization / copolymerization to produce the corresponding polymer.

[0049] ① replacement

[0050] a. Nitrogen replacement

[0051] After the bed is installed, control the nitrogen pressure to 0.7MPa, and after 10-20 times of p...

Embodiment 2

[0068] A method for quickly establishing ethylene polymerization / copolymerization in a 50kg / hr gas-phase fluidized-bed reactor, comprising the following steps:

[0069] After filling 100kg of suitable seed bed into the reactor, after introducing nitrogen to replace the trace amount of water and oxygen in the reaction system, switch to ethylene, hydrogen, comonomer and other circulating gases to adjust the composition, and then add 0.01kg of organic The chromium-based S-2 type catalyst initiates the establishment of the polymerization reaction, and then switches to a conventional chromium-based catalyst, and at the same time stops adding the organic chromium-based S-2 type catalyst, and uses a conventional chromium-based catalyst to catalyze ethylene polymerization / copolymerization to produce the corresponding polymer.

[0070] ① replacement

[0071] a. Nitrogen replacement

[0072] After the bed is installed, control the nitrogen pressure to 0.7MPa, and after 10-20 pressure r...

Embodiment 3

[0089] A method for quickly establishing ethylene polymerization / copolymerization in a 50kg / hr gas-phase fluidized-bed reactor, comprising the following steps:

[0090] After filling 100kg of suitable seed beds into the reactor, after introducing nitrogen to replace the trace amount of water and oxygen in the reaction system, switch to circulating gases such as ethylene, hydrogen, and comonomers to adjust the composition, and then add 0.05kg of organic The chromium-based S-2 catalyst initiates the establishment of a polymerization reaction, and then switches to a conventional chromium-based catalyst, while stopping the addition of an organic chromium-based S-2 catalyst, and uses a conventional chromium-based catalyst to catalyze ethylene polymerization / copolymerization to produce the corresponding polymer.

[0091] ① replacement

[0092] a. Nitrogen replacement

[0093] After the bed is installed, control the nitrogen pressure to 0.7MPa, and after 10-20 times of pressure repl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com