Trolley type wire aging annealing furnace

An annealing furnace and trolley-type technology, applied in the field of trolley-type wire aging annealing furnaces, can solve the problems of uneven annealing temperature of wire rods, affecting the tempering performance of wire rods, poor temperature uniformity, etc. Replacing quick effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

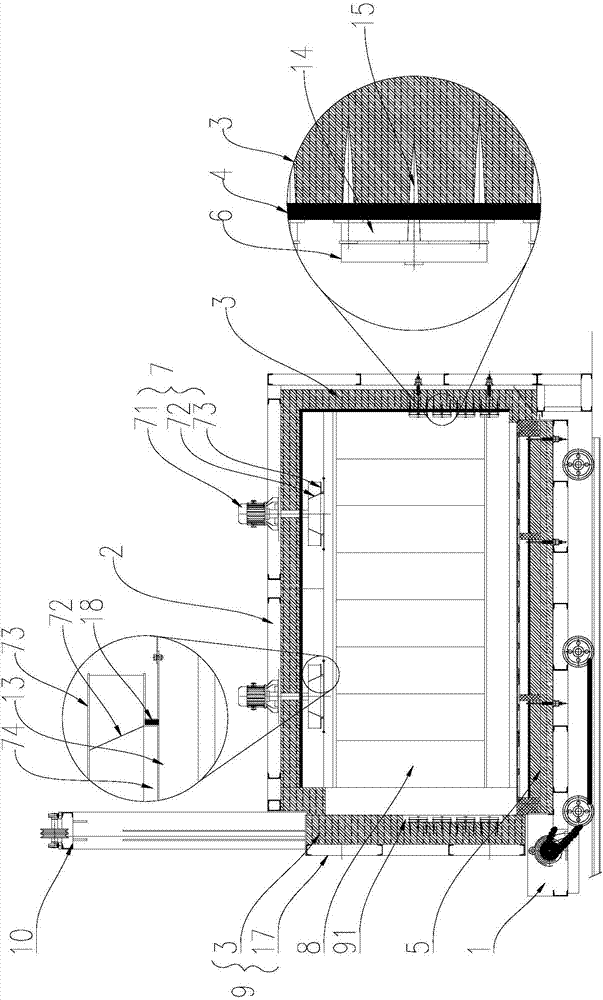

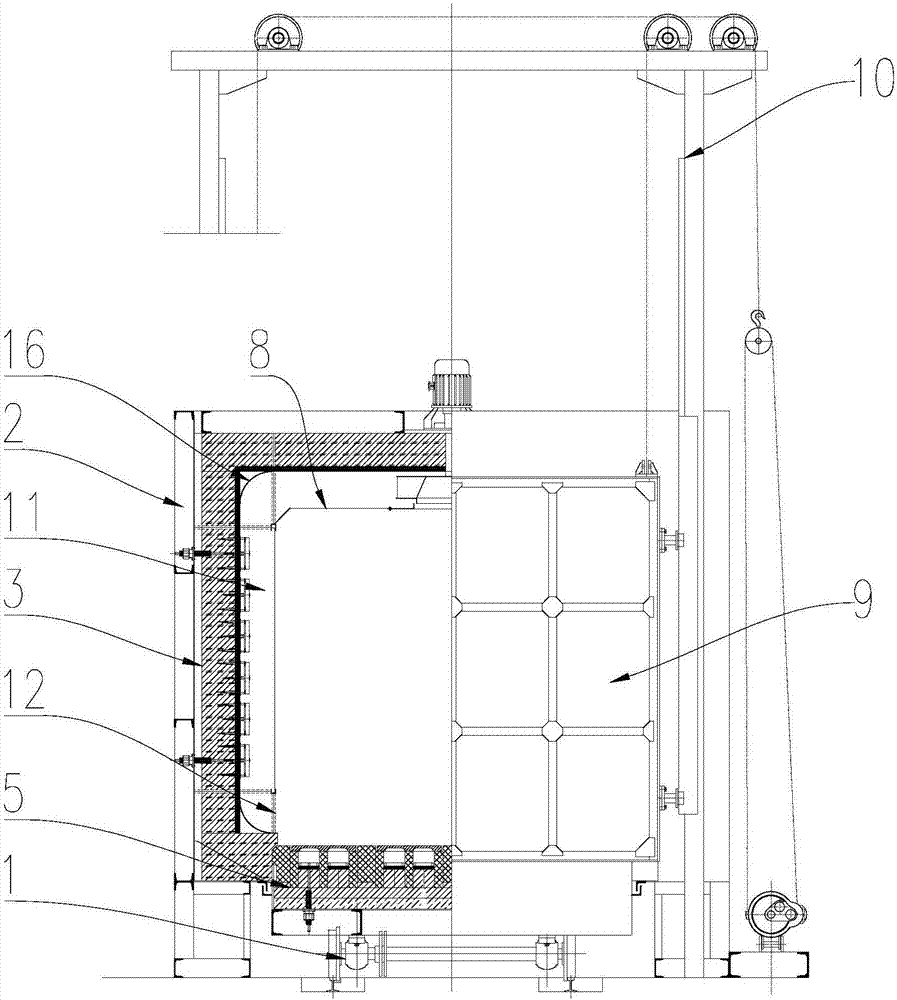

[0042] Such as figure 1 , figure 2 As shown, a trolley 1-type wire rod aging annealing furnace includes:

[0043] Trolley 1,

[0044] Furnace shell 2, set on the trolley 1, is used to maintain the strength of the furnace body, and is welded by channel steel and I-beam

[0045] The lining body 3, the lining body 3 is an insulation layer arranged on the top and side of the furnace shell 2, the lining body 3 is an aluminum silicate refractory fiber structure, and a layer of asbestos board 4 is attached to the inner surface of the lining body 3;

[0046] Underlayment 5, underlayment 5 is formed by laying refractory bricks;

[0047] The heating unit 6 is provided with a ceramic washer 14 between the heating unit 6 and the asbestos plate 4, and the ceramic washer 14 is fixed on the liner 3 by ceramic screws 15,

[0048] A hot air circulation device, the hot air circulation device includes a fan device 7 and a shroud 8;

[0049] Furnace door 9 and lifting mechanism 10;

[0050] ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap