Skid-proof shoe sole

An anti-slip and anti-slip sheet technology, applied in soles, footwear, applications, etc., can solve the problems of high safety hazards, reduce friction between the sole and the ground, low anti-skid practicability, etc., to improve anti-slip performance, The effect of increasing the excretion rate and improving the friction and anti-slip effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

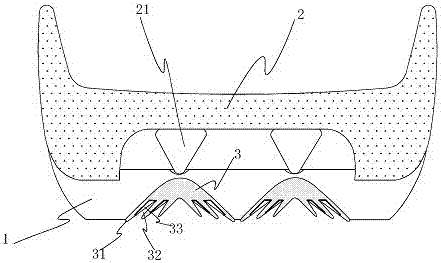

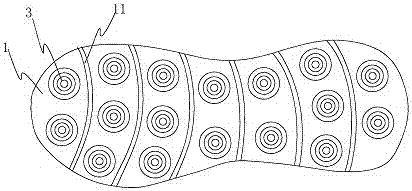

[0013] refer to Figure 1 to Figure 2 , Embodiment 1 of the present invention discloses that a non-slip shoe sole includes a large bottom 1 and a midsole 2 arranged on the large bottom. A plurality of conical protrusions 21 are provided, and the pointed ends of the conical protrusions 21 face the outsole 1; positioning grooves are provided on the upper surface of the outsole 1 corresponding to the positions of the conical protrusions hole, the pointed end of the conical protrusion 21 is placed in the positioning slot; the lower surface of the outsole 1 is provided with a conical slot at a position corresponding to the positioning slot, and The pointed end of the slot faces the positioning slot, and the conical anti-slip part 3 adapted to it is arranged in the conical slot, and the height of the conical anti-slip part 3 is greater than that of the conical slot The height of the conical anti-slip piece 3 is formed by stacking a plurality of conical anti-slip pieces 31 successiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com