Logistics sorting and conveying device

A conveying device and logistics technology, which is applied in the field of logistics sorting and conveying devices, can solve problems such as untimely delivery of goods and staff running back and forth, and achieve the effects of improving efficiency, improving conveying efficiency, and increasing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the drawings.

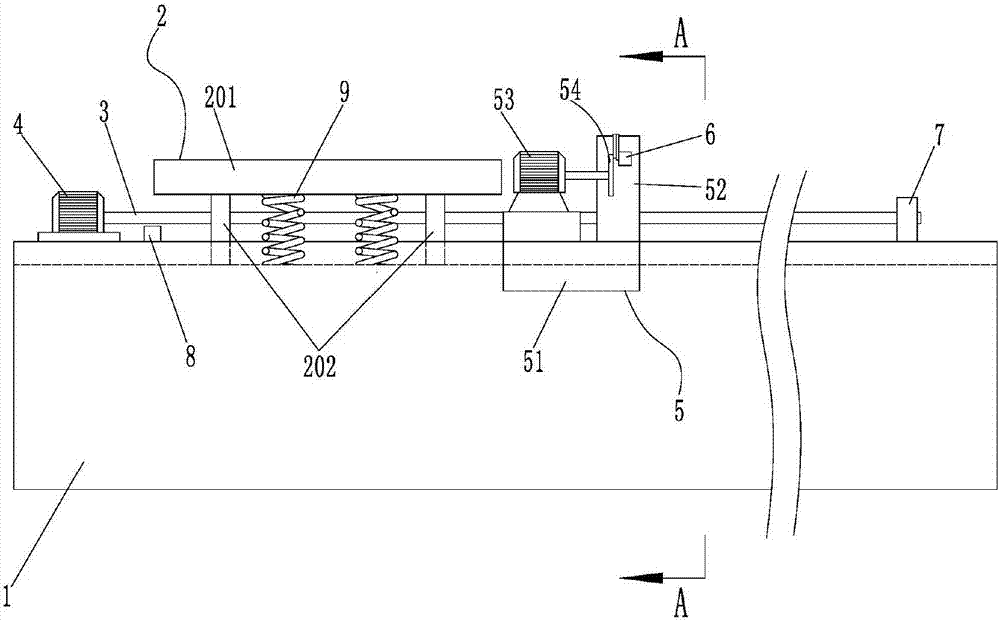

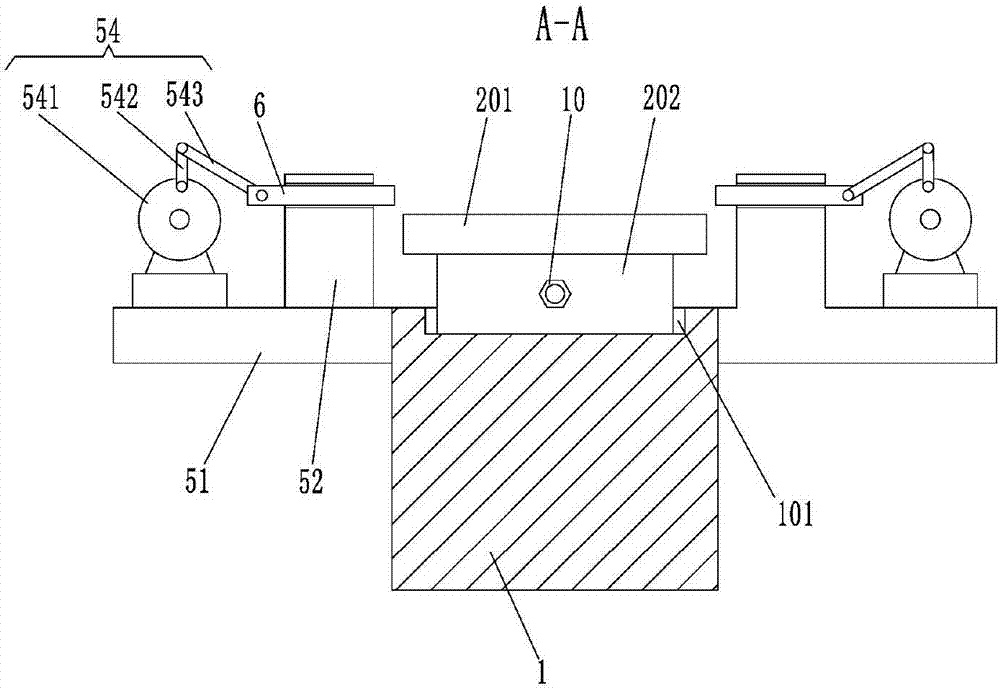

[0015] Such as Figure 1 ~ Figure 2 As shown, a logistics sorting and conveying device according to the present invention includes a base 1, a sliding groove 101 is opened on the base 1, and a transport rack 2 is slid in the sliding groove 101, and the transport rack 2 includes a transport plate 201 and a plurality of support plates 202, the support plate 202 is matched with the sliding groove 101, the transport plate 201 is fixed on the support plate 202; the center of the support plate 202 is pierced with a screw 3, the circumference of the screw 3 An external thread structure is provided on the upper part, and a nut 10 matching the outer thread structure is provided on the support plate 202; and one end of the screw rod 3 is connected with the transport motor 4 installed on the base 1, and the other end of the screw rod 3 It can be rotatably installed on the support 7 fixedly conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com