Integrated electric air compressor and fuel battery air inlet system with compressor

An air compressor and compressor technology, applied in fuel cells, electric components, electrical components, etc., can solve the problems of difficult layout of external cables and pipelines, low integration, electromagnetic interference, etc., to reduce electromagnetic interference and reduce assembly Complexity, effect of reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

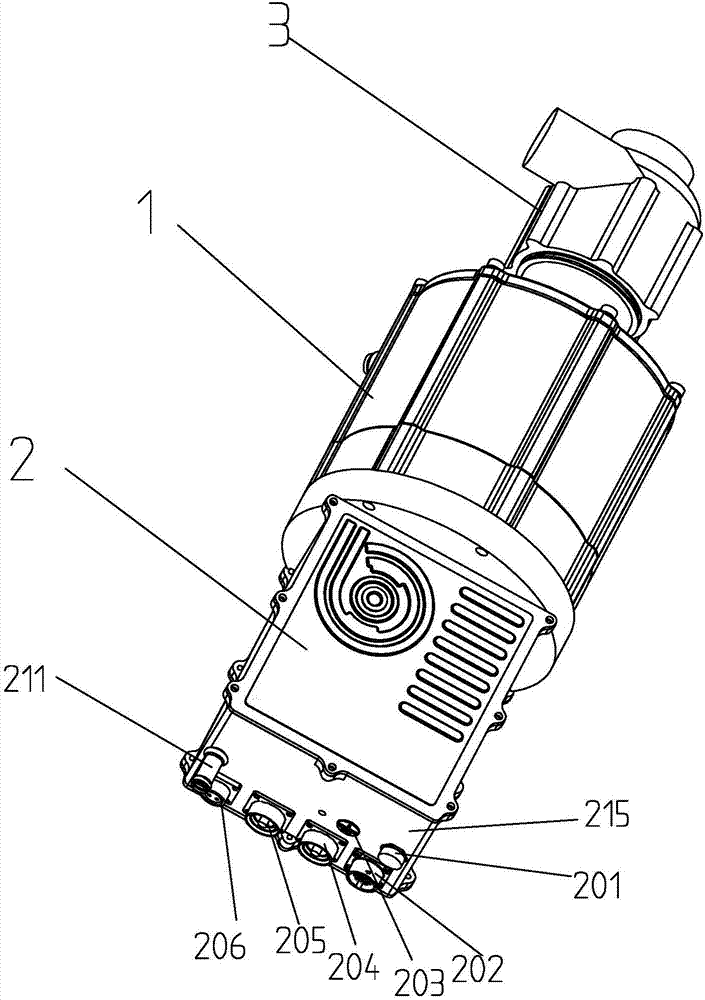

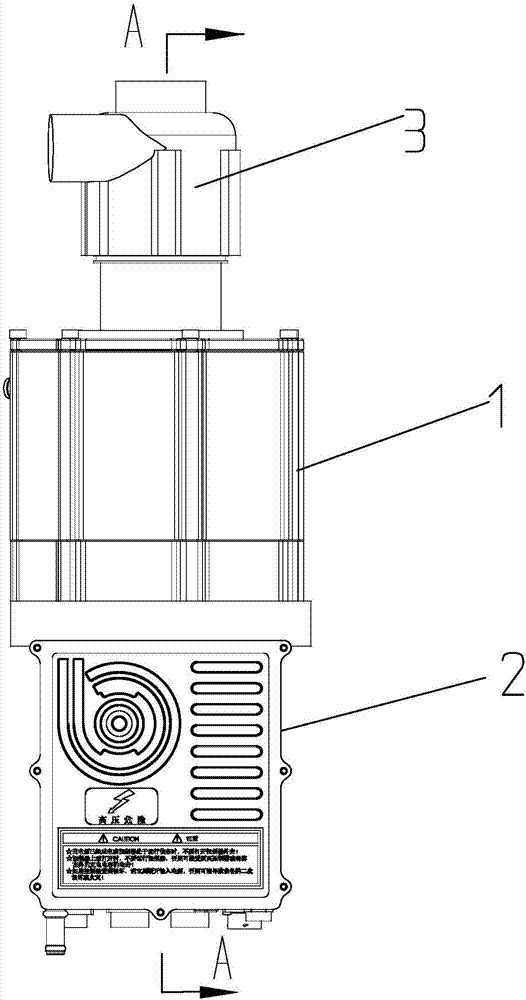

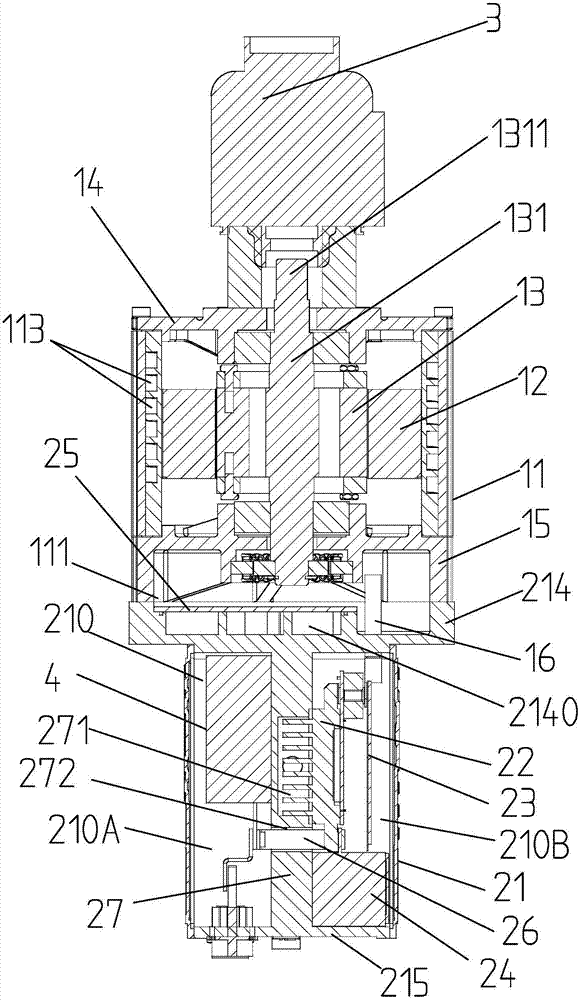

[0057] Such as Figure 1 to Figure 14 As shown, this embodiment provides an integrated electric air compressor, including a motor 1, a motor controller 2, and a compressor assembly 3. The motor 1 and the motor controller 2 form a motor drive system, and the motor 1 is a compressor The assembly 3 provides power. The motor 1 includes a housing 11 with a first liquid cooling channel 113 with a first liquid inlet 111 and a first liquid outlet 112, a stator assembly 12, a rotor assembly 13, a front end cover 14 and a rear end cover 15. The stator assembly 12 and the rotor assembly 13 are installed in the casing 11. The rotor assembly 13 includes a rotating shaft 131, and the end of the rotating shaft 131 extends from the front end cover to form a shaft extension end 1311;

[0058] The motor controller 2 is used to control the operation of the motor, and includes a drive module 22, a control circuit board 23, a capacitor module 24, a box with a second liquid cooling channel 213 with a ...

Embodiment 2

[0076] Such as Figure 15 As shown, a fuel cell air intake system of the present invention includes an air filter, a muffler, an integrated electric air compressor, an air cooler, and a humidifier. The external cold air passes through the filter, muffler, and integrated electric air The compressor, air cooler and humidifier provide compressed air to the fuel cell stack. Such as Figure 16 As shown, the self-starting integrated air compressor adopts the integrated electric air compressor described in the first embodiment, and it also includes a low-voltage power supply, which passes through a DC-DC converter 4 installed in the box. The conversion into high voltage provides the working energy of the start-up phase to the motor drive system.

[0077] Such as Figure 17 As shown, the DC-DC converter is connected with a control switch 200. When the fuel cell system reaches the normal operating voltage, the DC-DC converter 4 is automatically disconnected by the control switch 200, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com