Steam boiler

A steam boiler and steam outlet technology, applied in steam generation, steam generation method, steam separation device, etc., can solve the problems of lower energy utilization rate, large floor area, heat loss, etc., to ensure safe use, stable pressure, Effect of reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0022] For the convenience of description, the upward direction of vapor is defined as upward, and the downward direction of water flow is defined as downward.

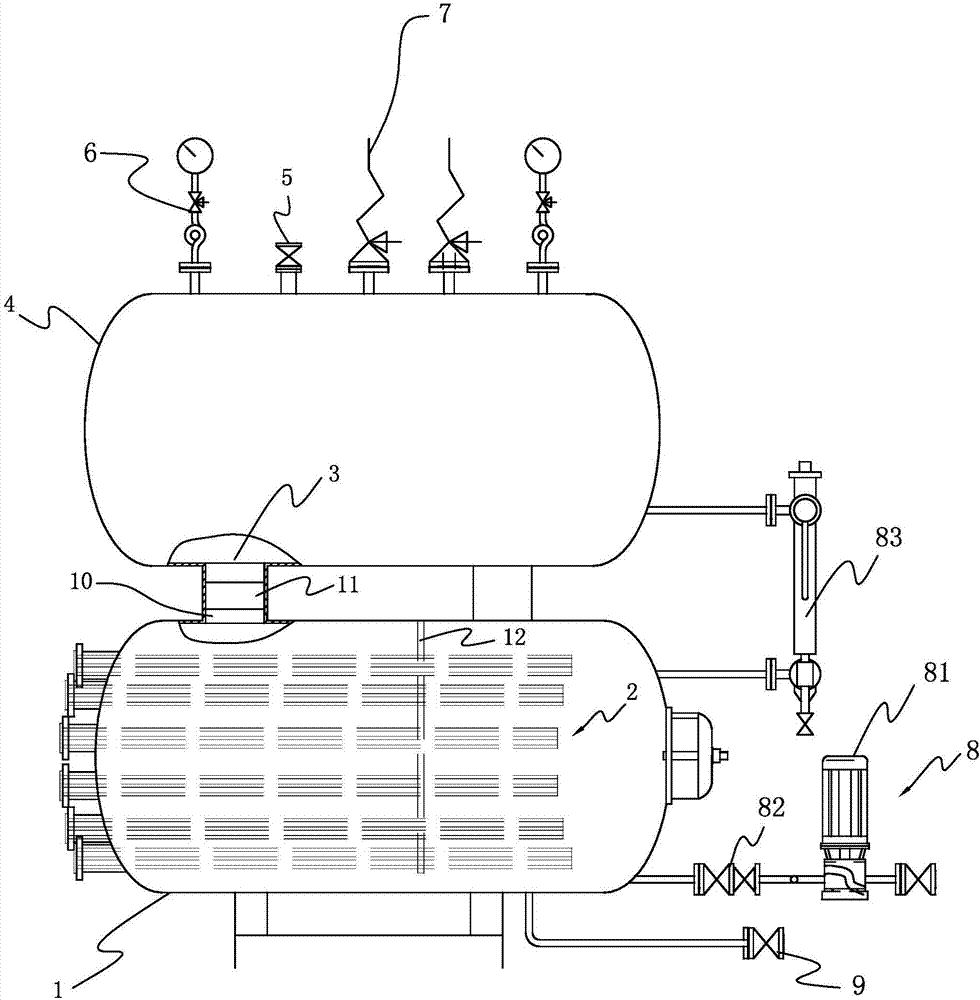

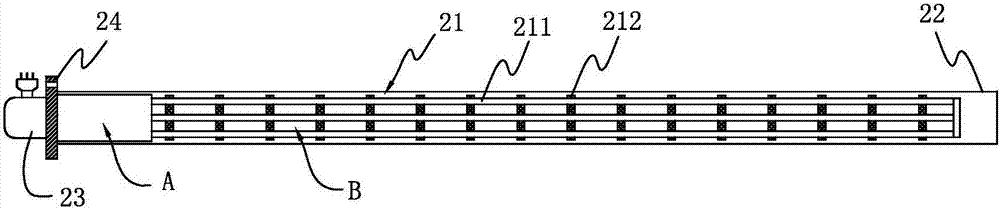

[0023] Such as figure 1 As shown, a steam boiler, the furnace body 1 is a shell, and the water in it is heated through the electric heating radiant tube 2, the electric heating is energy-saving and environment-friendly, it is convenient for automatic control, and the heating speed is fast. The furnace body 1 is provided with a furnace body water inlet and a furnace body steam outlet 3, a steam storage tank 4 is arranged above the furnace body 1, the furnace body steam outlet 3 and the steam storage tank 4 are connected through a support pipe 10, and the support pipe 10 is provided with There is a steam-water separator 11, which separates the steam generated by heating in the furnace body 1, ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap