Test device for determining life of steel wire under coupling effect of corrosion and fatigue, and method thereof

A corrosion fatigue and test device technology, which is applied in the direction of measuring device, testing material strength by applying repetitive force/pulsation force, testing wear resistance, etc., can solve problems such as multiple steel wire test, unsteel wire life test evaluation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing.

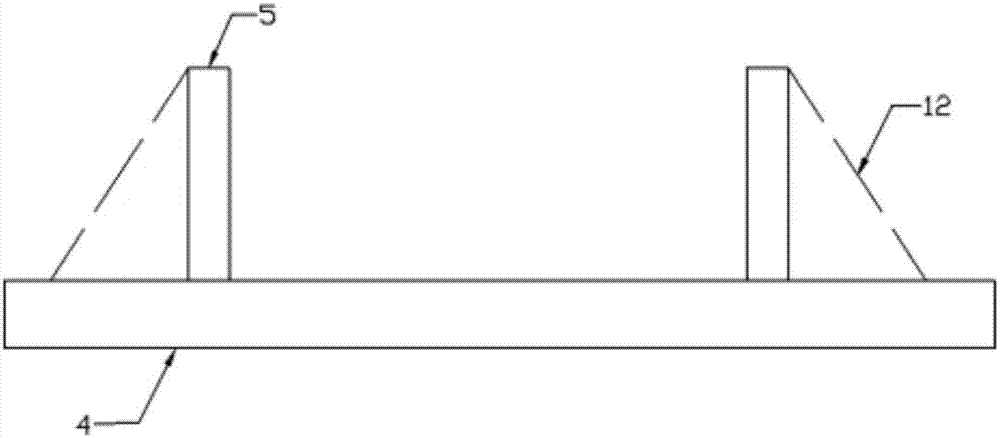

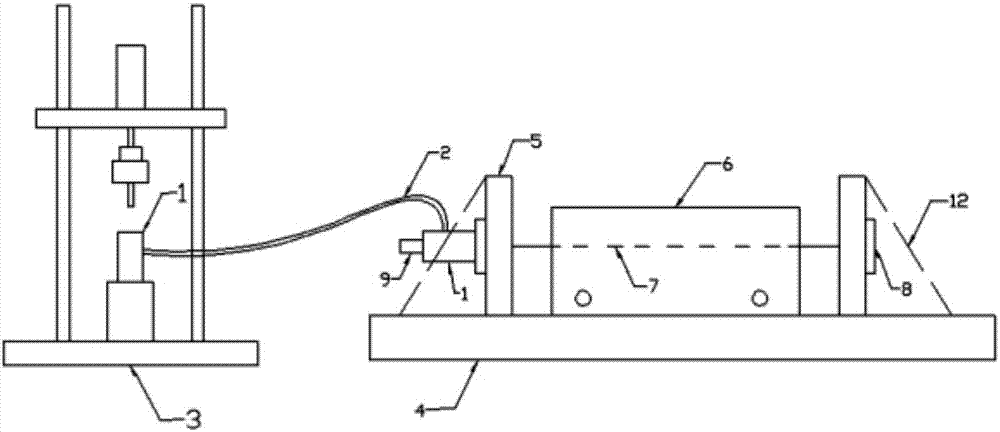

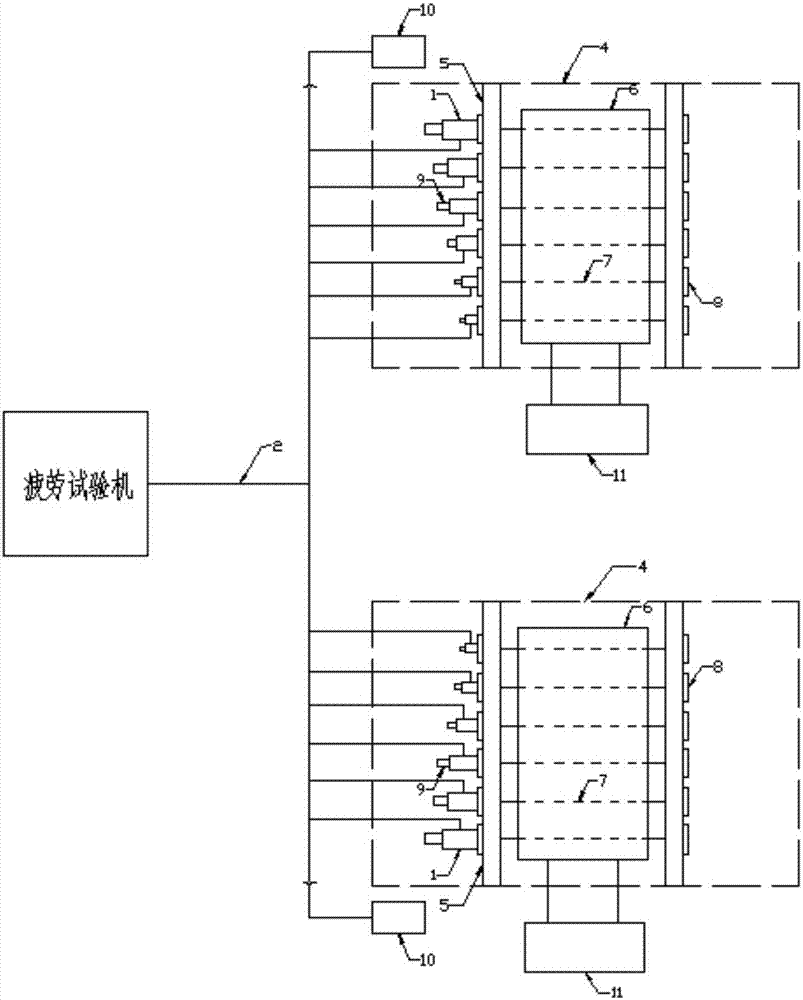

[0022] Such as figure 1 As shown, the reaction frame is designed according to the size and quantity of the steel wires. Its strength can meet the fatigue of multiple steel wires at the same time. It is welded by steel plates, including the column 5, the brace 12 and the support 4. The diagonal brace 12 is connected and fixed to the support 4, and the side of the column 5 is connected to the hydraulic jack 1, and the hydraulic jack 1 is connected to the oil circuit 2. The number of the columns 5 is two, and the two columns are vertically arranged on the support 4 at intervals. Above, the column 5 has a round hole to connect the anchor 8, the anchor 8 is used to fix the hydraulic jack 1 and the steel wire 7, and the hydraulic jack 1 is also provided with a sensor 9; image 3 As shown, the corrosion circulation container is made up of the corrosion container 6, the circulatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com