A novel resonant acoustic nondestructive test device

A non-destructive testing and acoustic technology used in measuring devices, scientific instruments, analysis of solids using sonic/ultrasonic/infrasonic waves, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is described below by way of embodiment.

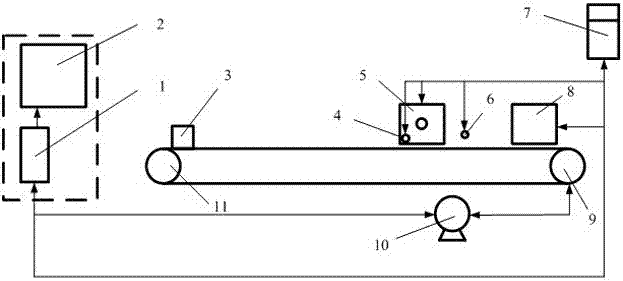

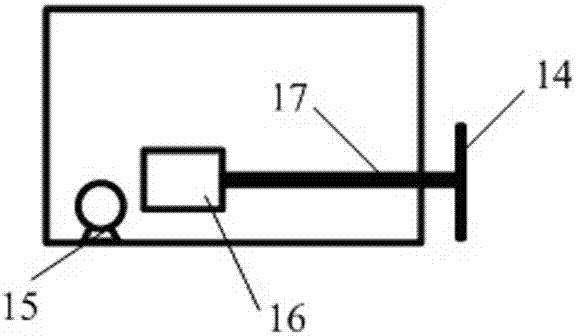

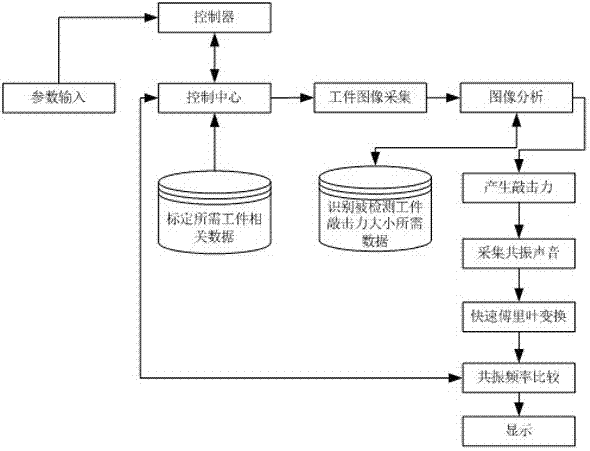

[0024] Such as figure 1 , 2As shown, a resonance non-destructive testing device is provided, and its structure includes: a transmission device, a percussion device, a resonance sound collection device, a signal processing, a control device and a defect workpiece processing device; wherein, the transmission device is composed of a transmission belt 13, a transmission belt driving wheel 9. Conveyor belt driven wheel 11 and variable speed motor 10; the percussion device is composed of CCD sensor 4, intelligent controller 1 for signal acquisition and data processing and automatic percussion hammer 5; the resonance sound collection device is a high-precision microphone 6; The signal processing and control device is an intelligent controller 1 for signal acquisition and data processing; the defect workpiece processing device is figure 1 8 in, its structure is as image 3 shown.

[0025] During work, the work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com